Omni-directional mobile robot for machine tool table changeover

An omnidirectional mobile and robotic technology, applied in the field of omnidirectional mobile robots and large CNC machine tools, can solve problems such as affecting the efficiency of machine tools and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

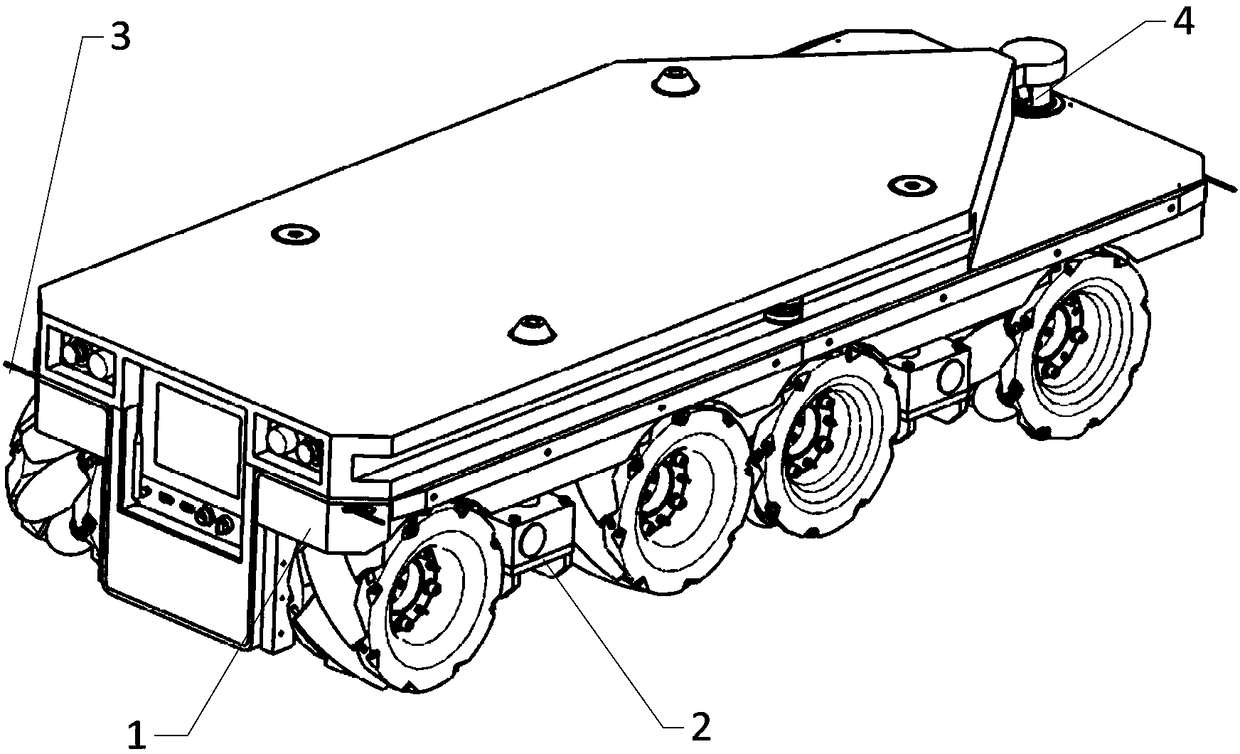

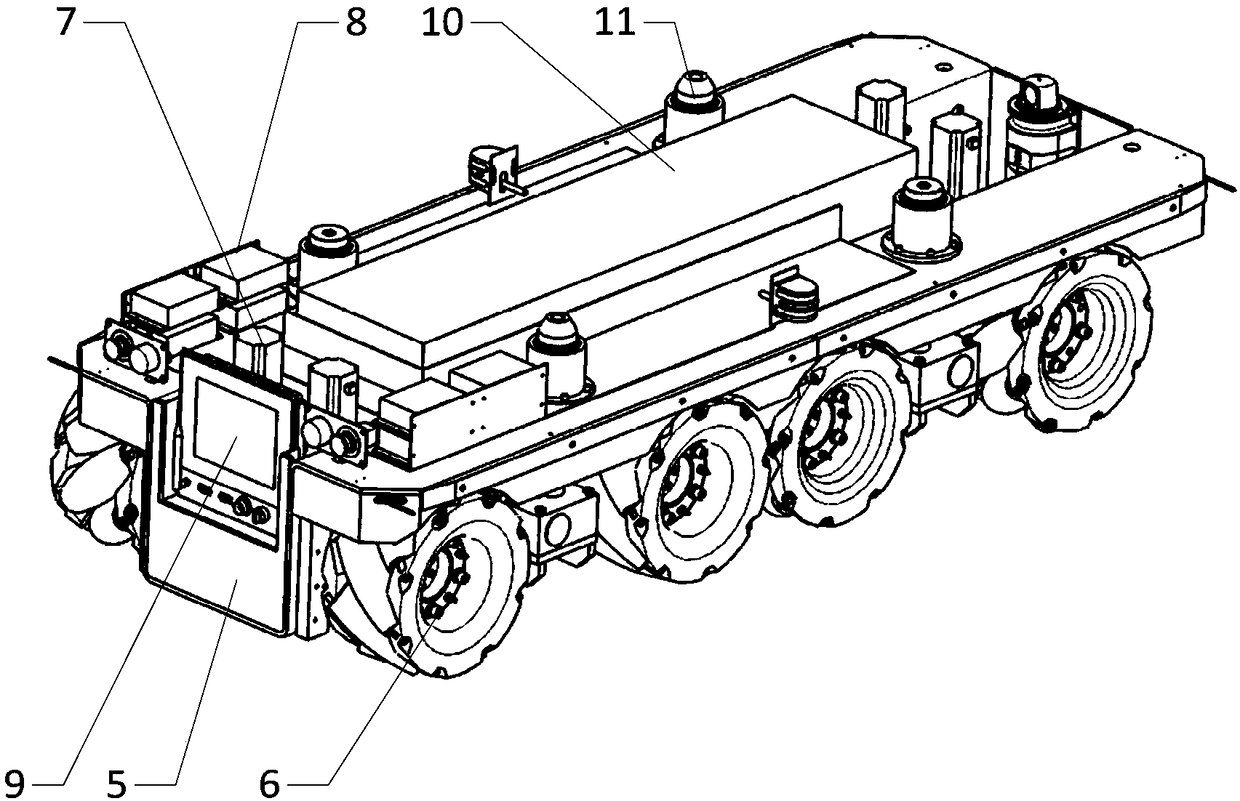

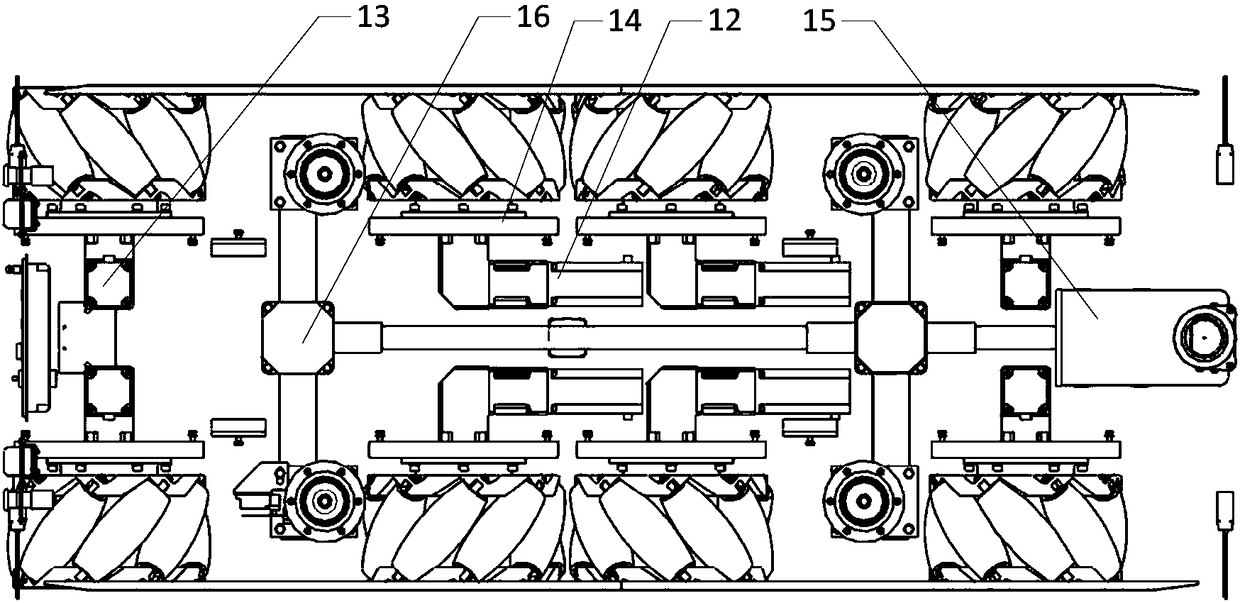

[0021] Such as figure 1 As shown, the embodiment of the present invention provides an omnidirectional mobile robot for machine tool workbench replacement, including a mecanum wheel omnidirectional mobile chassis 1, a four-legged synchronous lifting screw jack suit 2, a whisker sensor 3 and Laser reflective positioning and navigation sensor 4;

[0022] Such as figure 1 , figure 2 As shown, the omnidirectional mobile chassis 1 with mecanum wheels is used as the walking mechanism of the omnidirectional mobile robot; the four-legged synchronous lifting screw jack set 2 is fixedly installed on the chassis frame 5 of the omnidirectional mobile chassis 1 with mecanum wheels ; Four cat whisker sensors 3 are installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com