Gas separation device and method based on front and rear depropanization double-tower process

A front depropanizer and rear depropanizer technology, which is applied in the purification/separation of hydrocarbons, chemical instruments and methods, climate sustainability, etc., can solve the problems of low thermal energy level, high energy consumption, and high thermal energy level. The effect of reducing the thermal energy level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

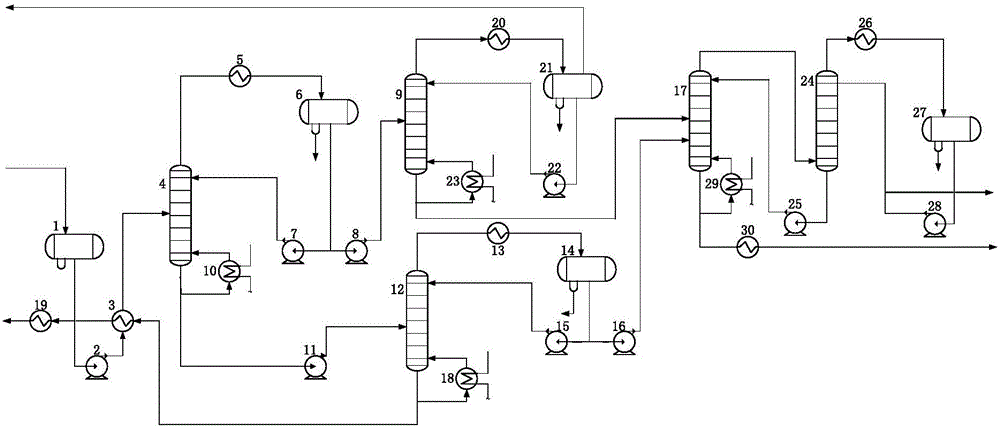

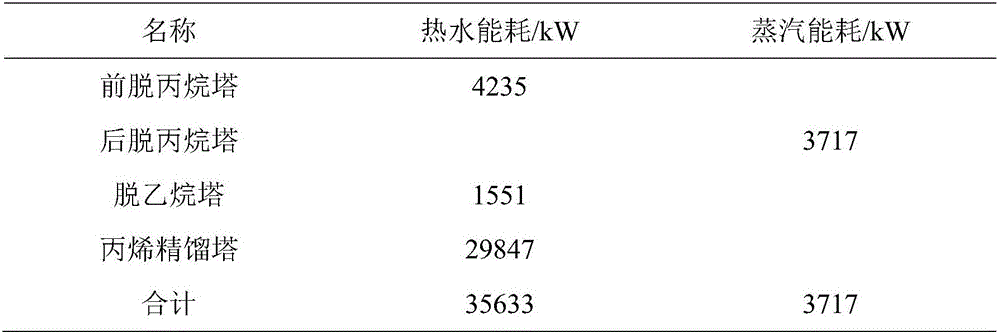

[0026]Taking a certain gas separation device as an example, the process described in the present invention is adopted. Feed amount is 50000kg / h, feed composition: ethane 0.2%wt%, propane 11.5%wt%, propylene 41.3%wt%, n-butane 6.3%wt%, isobutane 13.6%wt%, n-butene 3.4% wt%, 1-butene 13.5% wt%, cis-2-butene 4.6% wt%, trans-2-butene 5.6% wt%. The theoretical plate number of the front depropanizer is 65, the feeding position is the 25th plate, the operating pressure is 1.7MPag, the output of the top of the front depropanizer is 17000kg / h, and the C3 content of the produced product is controlled above 99.6%wt% ; The output at the bottom of the front depropanizer is 33000kg / h, and the C4 content of the extracted product is controlled above 71.2%wt%. The theoretical plate number of the deethanizer is 47, the feeding position is the 19th plate, the operating pressure is 2.65MPag, the output of the deethanizer is 251kg / h, and the carbon dioxide content of the produced product is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com