Press fitting type clothes ironing device

A press-fit, garment technology, applied in washing devices, wrinkle-removing and flattening equipment, textiles and papermaking, etc., can solve the problems of crushed buttons, difficulty in grasping the degree of fit between the heating plate and the ironing board, and poor ironing. , to achieve a high degree of automation, good ironing effect, and improve the effect of ironing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

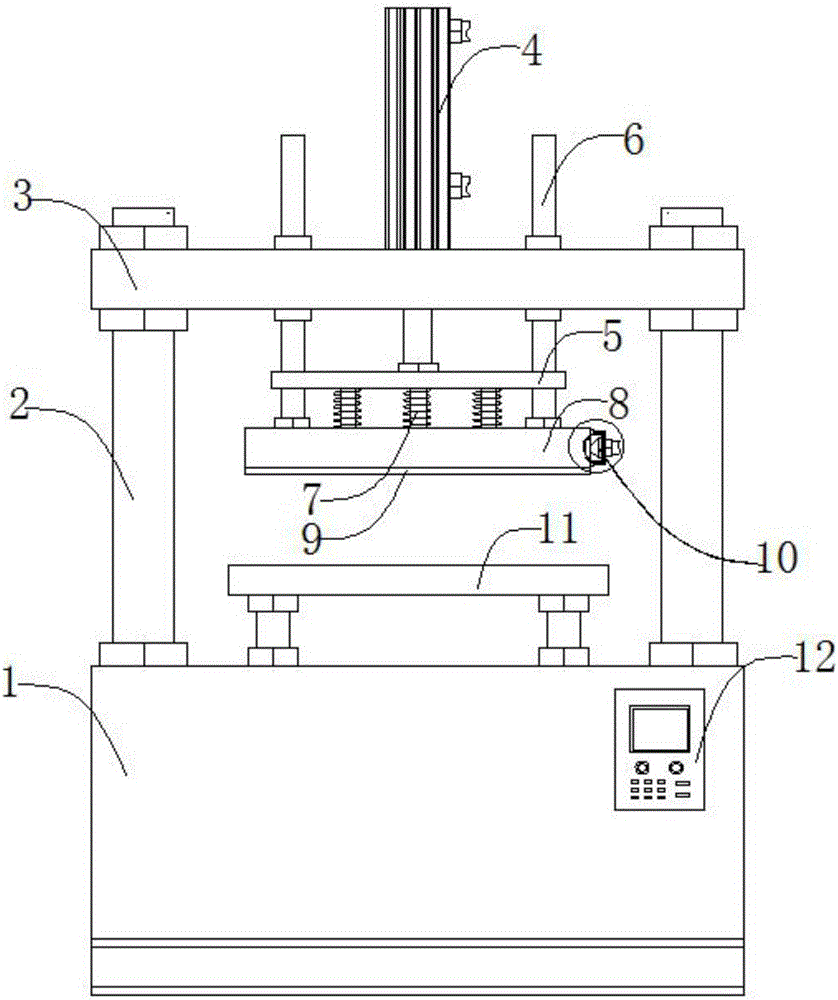

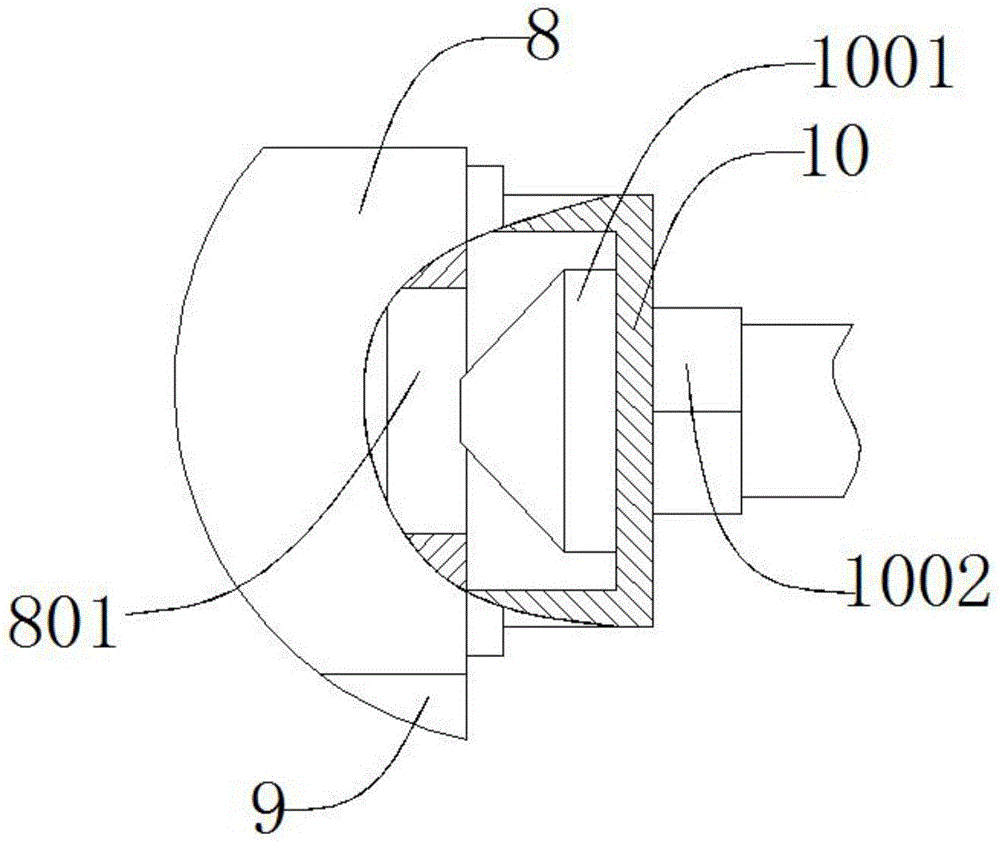

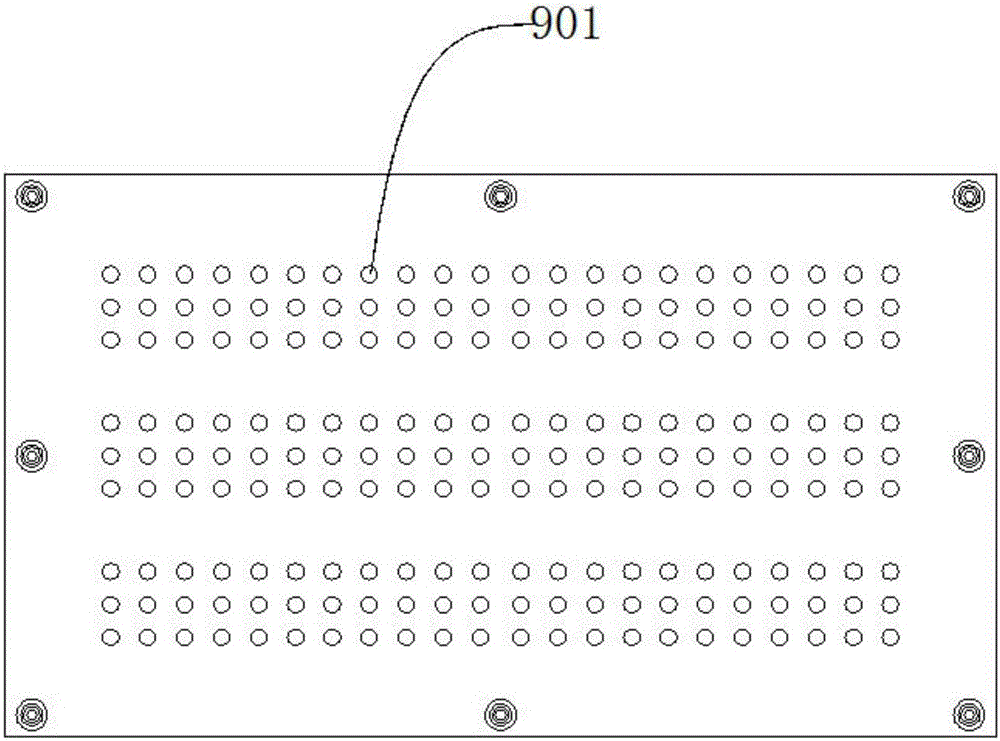

[0022] Such as figure 1 , figure 2 , image 3 As shown, a press-fit clothing ironing device includes a machine base 1, a column 2, a supporting plate 3, a cylinder 4, a sliding plate 5, a guide rod 6, no less than 3 pieces of springs 7, a steam box 8, and an upper heat conducting Plate 9, buffer box 10, lower heat conducting plate 11, controller 12, the column 2 is located at the upper end of the machine base 1, the column 2 is threadedly connected with the machine base 1, and the supporting plate 3 is located at the upper end of the column 2, The supporting plate 3 is threadedly connected with the column 2, the cylinder 4 is located at the upper end of the supporting plate 3, the cylinder 4 is threadedly connected with the supporting plate 3, the sliding plate 5 is located at the lower end of the cylinder 4, and the sliding The plate 5 is threadedly connected with the cylinder 4, the guide rod 6 runs through the supporting plate 3 and the sliding plate 5, the guide rod 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com