New Fatigue Resistant Steel Wire Rope Production Line and Its Production Process

A production process and steel wire rope technology, applied in the new fatigue-resistant steel wire rope production line and its production process, can solve the problems of long service life, lower production efficiency, and impact on service life, so as to improve fatigue resistance, prolong service life, physical The effect of performance tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

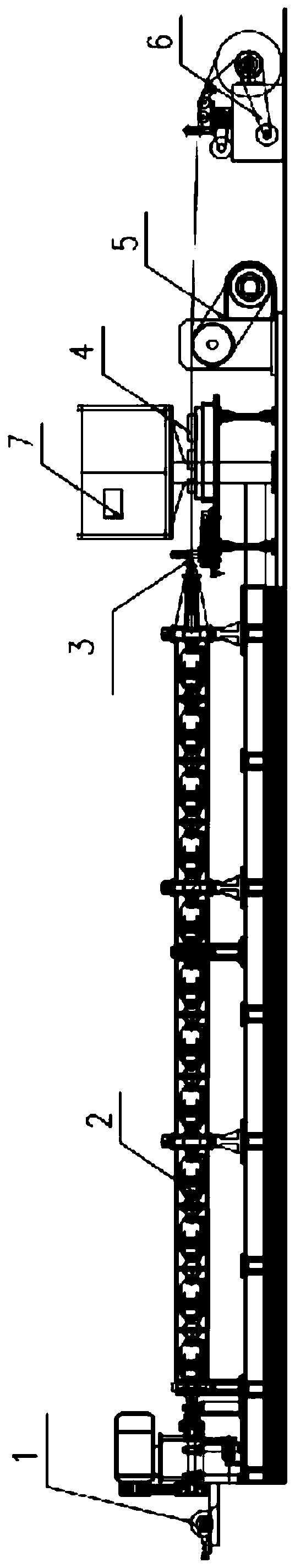

[0071] Such as Figure 1-6 As shown, the new fatigue-resistant steel wire rope production line sequentially includes a wire drawing device 1, a twisting device 2, a rope closing device 3, a shaping mechanism 4, a traction device 5, and a winding device 6. There is a fatigue-resistant oil dripping device at the closing mouth of the wire mold. The fatigue-resistant oil dripping device is installed here, so that the oil on the wire rope can be evenly and fully penetrated.

[0072] The traction device 5 is a servo traction meter counting device.

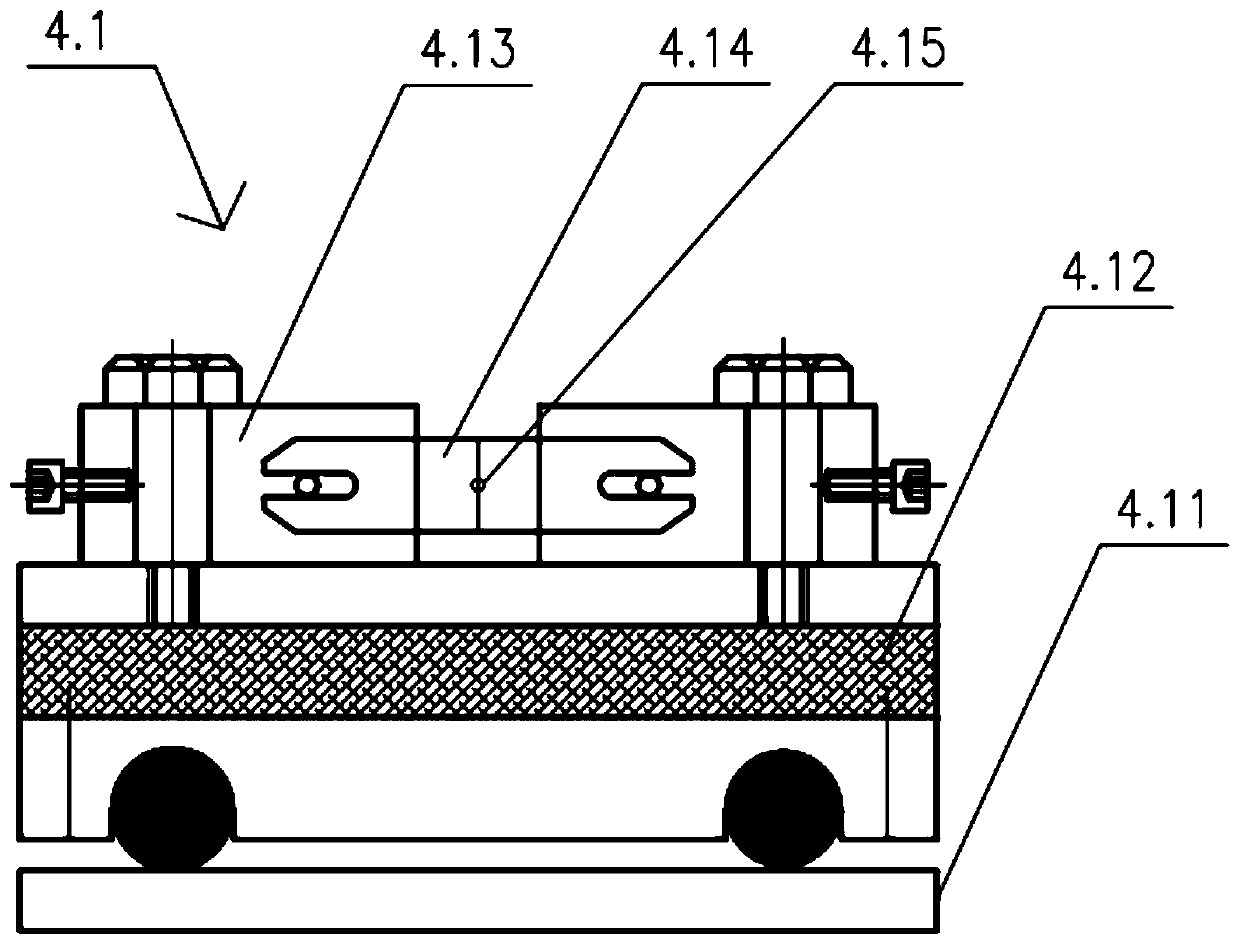

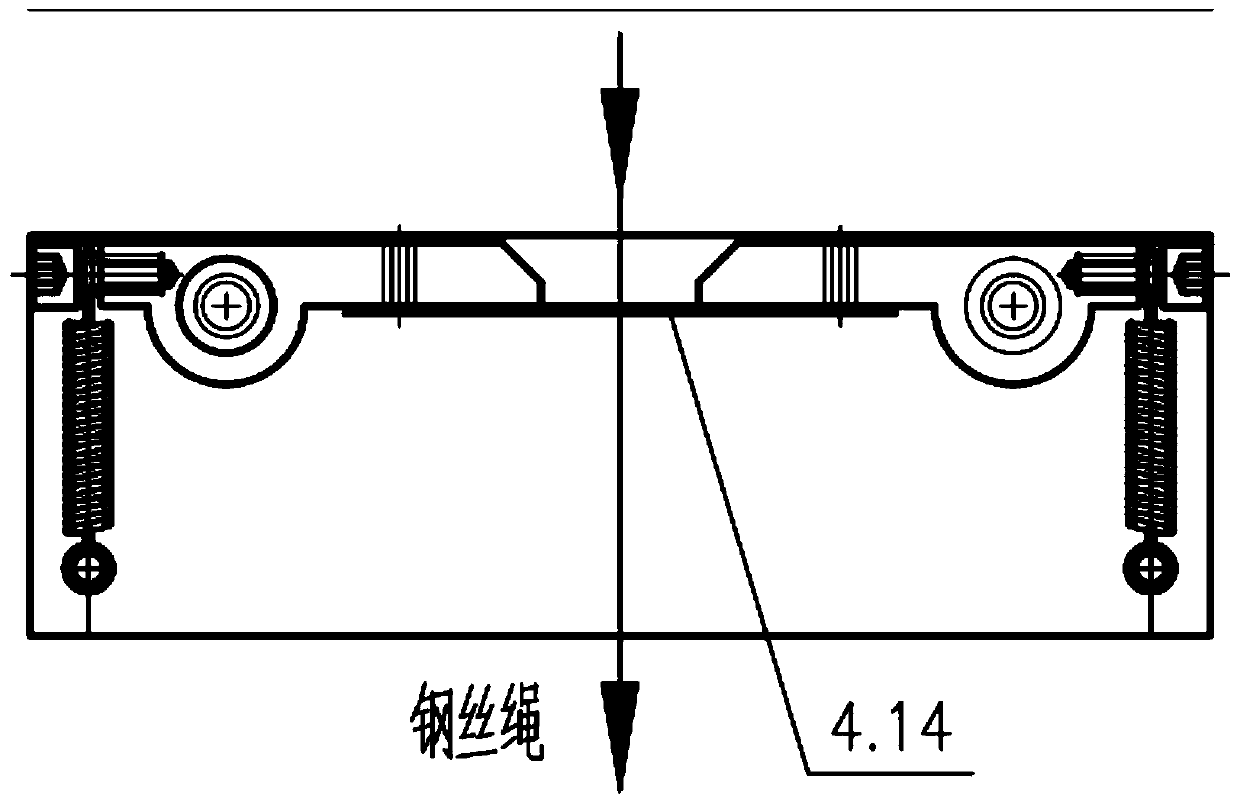

[0073] The shaping mechanism 4 sequentially includes a burr detection device 4.1, a rough shaping device 4.2, and a fine shaping device 4.3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com