Door plate sealing mechanism

A sealing mechanism and door panel technology, applied in the field of doors, can solve the problems of door wear, gap between the door and the floor, and the door panel does not have sound insulation and sealing, so as to achieve accurate control, improve reliability, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

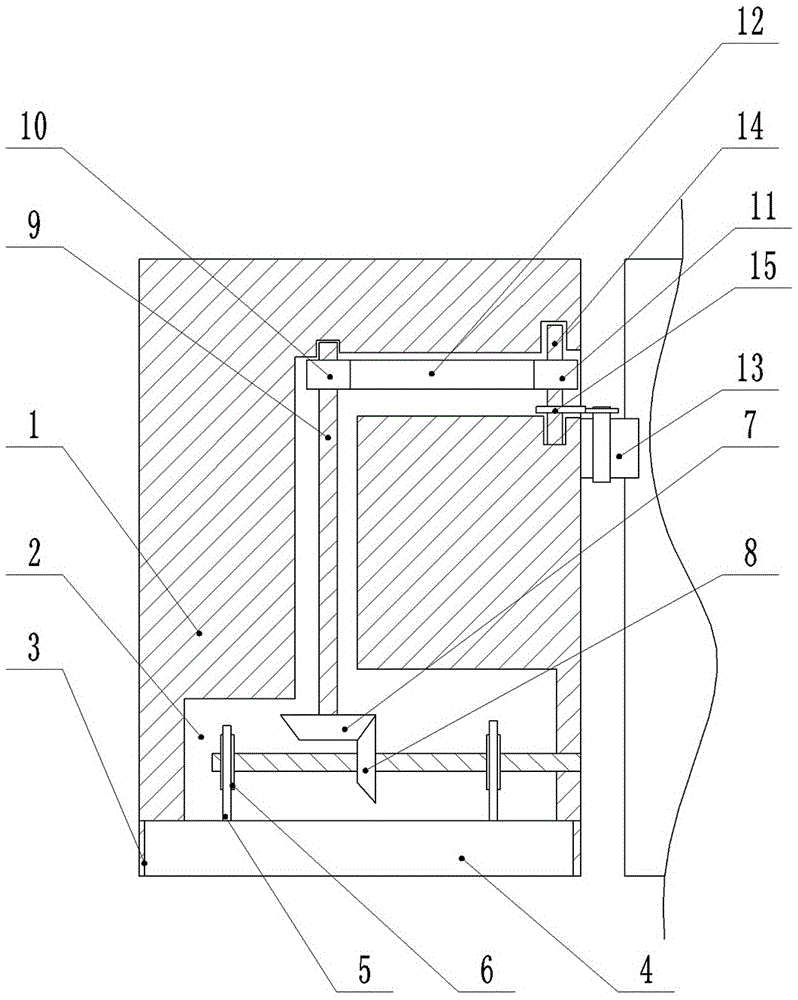

[0026] Basic as attached figure 1 Shown: a door panel 1 sealing mechanism in this scheme is arranged on the door panel 1. A mounting slot 2 is opened in the door panel 1, and a sealing unit is installed in the mounting slot 2, and the hinge 13 is welded with a transmission gear and a transmission tooth path The left side is matched with the sealing unit. The sealing unit includes a second gear 15 matched with the transmission gear. The second gear 15 has a first transmission shaft 14 in interference fit. The upper part of the first rotating shaft is in interference fit with a first pulley 11, A second pulley 10 is installed on the left side of a pulley 11, and a conveyor belt 12 is connected between the first pulley 11 and the second pulley 10.

[0027] The second pulley 10 is provided with a second transmission shaft in interference fit. The lower part of the second rotating shaft is in interference fit with a first bevel gear 7 arranged horizontally. The first bevel gear 7 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com