Underground sliding sealing tool, infinite extension drilling device and drilling method thereof

A sliding sealing and sealing device technology, which is applied in the drilling driving device, drilling equipment and method, drilling equipment and other directions in the wellbore, can solve the problems of limited drilling extension ability, improve the rock breaking efficiency and reduce the rock breaking efficiency. Difficulty, the effect of reducing the number of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

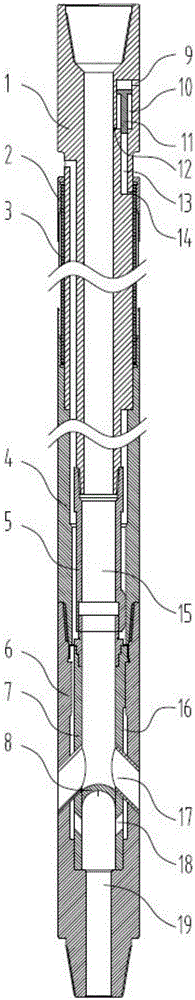

[0039] Such as figure 1 and 2As shown, this embodiment provides a downhole sliding sealing tool, including a downhole power device and a sealing device installed on the downhole power device. The downhole power device includes an upper mandrel 1, a middle mandrel 4, and a lower mandrel 6. Wherein the upper mandrel 1, the middle mandrel 4 and the lower mandrel 6 are all hollow structures. In this embodiment, the hollow part at the top of the upper mandrel 1 is a tapered structure with a wide top and a narrow bottom, and the inner surface of the tapered structure is screwed with the drill pipe 20 . The middle mandrel 4 is an axially symmetrical structure, the upper part of the middle mandrel 4 is fixedly connected with the lower part of the upper mandrel 1 through an internal thread, and the lower part of the middle mandrel 4 is fixedly connected with the upper part of the lower mandrel 6 through an external thread. The lower part of the lower mandrel 6 is threadedly connected...

Embodiment approach 2

[0041] Such as figure 1 As shown, the first embodiment is further optimized, the lower casing 7 is installed in the lower mandrel 6, and the lower casing 7 and the middle mandrel 4 are fixed by the rubber fixing sleeve 5 of the packer, wherein , the hollow part below the lower shell 7 in the lower mandrel 6 constitutes the lower central flow channel 19, the gap between the lower mandrel 6 and the lower shell 7 forms the flow channel 16 between the double walls, and the upper central The flow channel 15, the lower central flow channel 19 and the flow channel 16 between the double walls communicate with each other. As a preference of this embodiment, the inner diameter of the upper central flow channel 15 is larger than the inner diameter of the lower central flow channel 19 .

[0042] Such as figure 1 As shown, this embodiment is further optimized, a plug 8 is set in the middle of the lower central flow channel 19, the upper central flow channel 15 communicates with the outer...

Embodiment approach 3

[0044] To further optimize Embodiment 1 or Embodiment 2, a plunger cylinder 13 is provided at the bottom of the piston cylinder 10, the piston cylinder 10 communicates with the plunger cylinder 13, and the piston in the piston cylinder 10 is connected to the piston cylinder 13. The plunger 11 is integrally connected, and the lower part of the plunger barrel 13 is provided with an oil injection hole for delivering pressurized hydraulic oil from the piston barrel 10 to the gap between the upper mandrel 1 and the rubber barrel 3 of the open hole packer 14. As a preference of this embodiment, the inner diameter of the piston barrel 10 is larger than the inner diameter of the plunger barrel 13 .

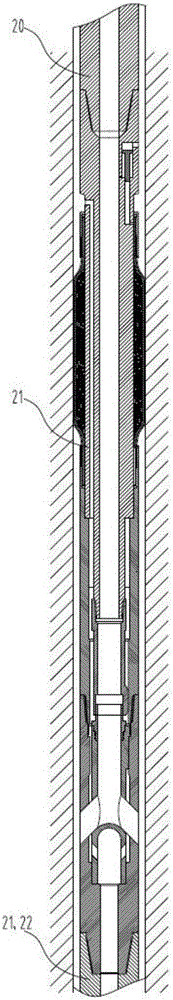

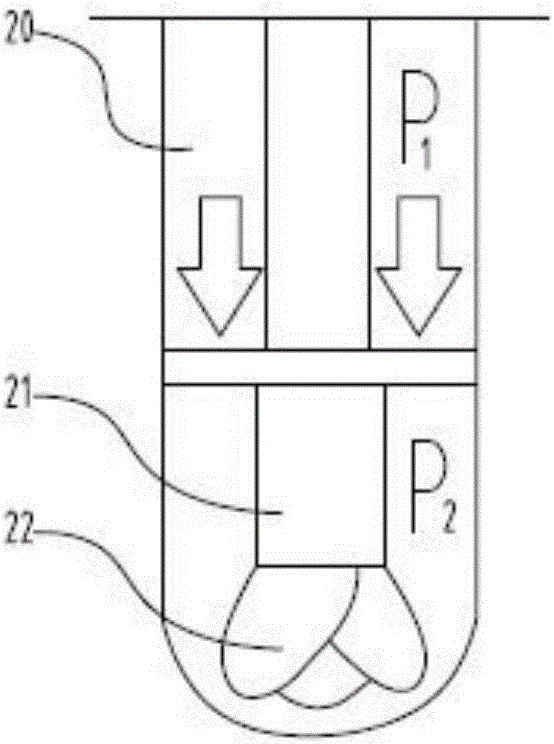

[0045] This embodiment also provides a drilling device with infinite extension, including a drill pipe 20, a screw power drill 21 and a PDC drill bit 22, and also includes the downhole sliding sealing tool described in this embodiment, the upper part of the downhole sliding sealing tool a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com