A hydraulic pulse generating device and its operating method

A pulse generating device and hydraulic technology, applied in the direction of vibration drilling, etc., can solve the problems such as the influence of the structure size of the lower drilling tool, and the technology cannot be applied universally, so as to achieve convenient operation, increase the rock breaking speed, and the device structure is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

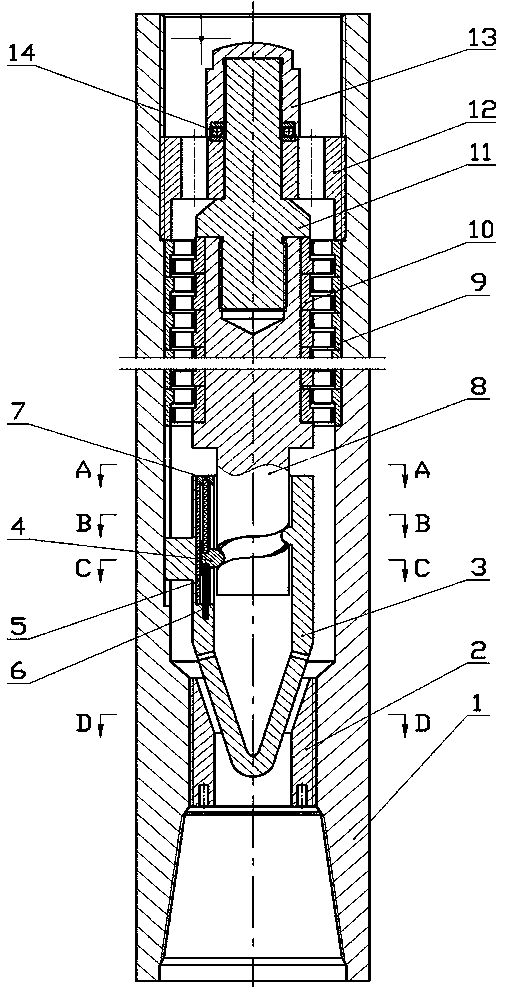

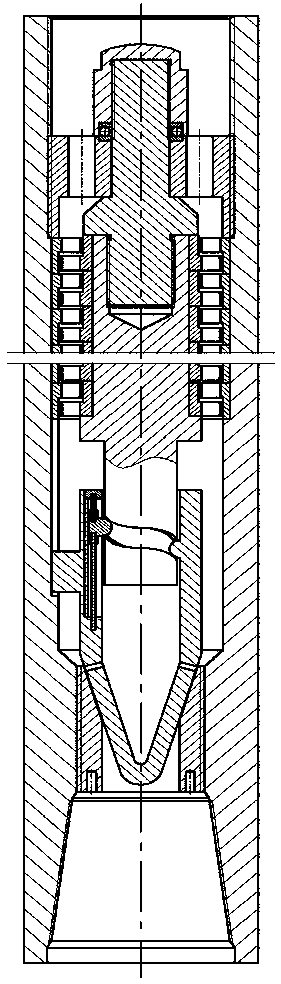

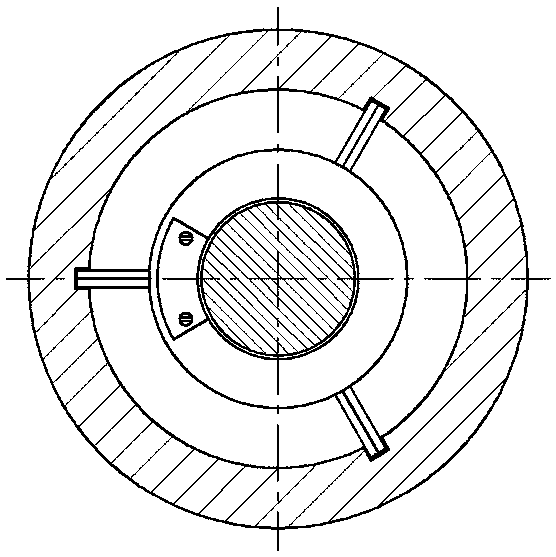

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-11 As shown, a hydraulic pulse generating device is mainly composed of a housing 1, a throttle nipple 2, an elastic nipple 3, a centralizing block 4, a gasket 5, a spring 6, a spring cover 7, a transmission shaft 8, and a turbine stator 9. The turbine rotor 10, pull rod 11, support plate 12, support cap 13, and thrust bearing 14 are characterized in that: the throttle nipple 2 is connected to the lower end of the housing 1 through threads, and the throttle nipple 2 is connected to the spring The short joint 3 forms a hydraulic pulse generating unit, and the centralizing block 4 is installed in the T-shaped slot of the short joint 3. The T-shaped slot of the short joint 3 is provided with a gasket 5 and the upper and lower ends of the centralizing block 4. Both are equipped with springs 6, and the spring cover 7 is used to prevent the spring 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com