Small-aperture rock breaking drill bit

A small-diameter, drill-bit technology, applied in construction and other directions, can solve the problems of reducing rock-breaking efficiency, restricting hole-forming efficiency, and impact on slag-discharging efficiency, and achieves the goal of increasing rock-breaking speed, reducing drilling slag size, and improving hole-forming efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

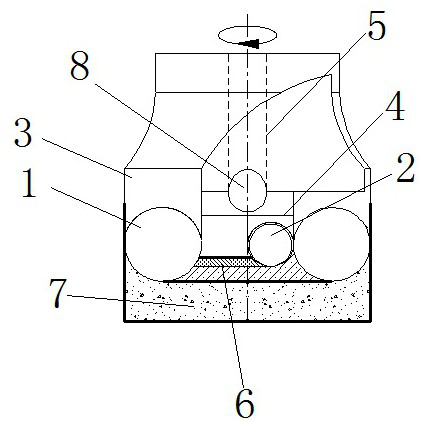

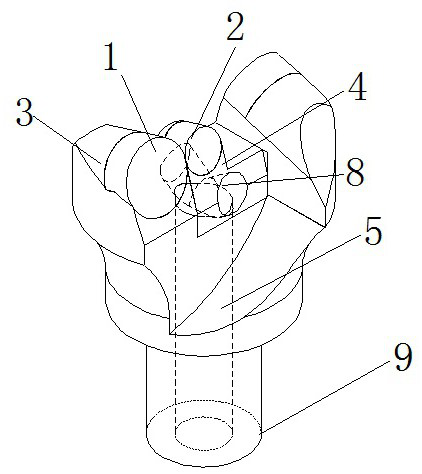

[0016] Such as Figure 1-2 As shown, a small-aperture rock-breaking drill bit includes a drill bit connecting portion 9, and the top of the drill bit connecting portion 9 is provided with an outer blade 3 and a central blade 4, and the outer blade 3 is arranged on the outside of the central blade 4 , the outer blade 3 is provided with an outer rock cutting blade 1, the outer rock cutting blade 1 is arranged on the outer edge of the drill bit connecting portion 9, the center blade 4 is provided with a central rock cutting blade 2, the center The rock cutting blades 2 are arranged between the outer rock cutting blades 1, the center of the drill bit connecting portion 9 is provided with a drill bit center hole 5, and the top of the drill bit center hole 5 is provided with a double-sided inclined hole 8, and the double-sided inclined hole 8 The two ends are respectively arranged on the outside of the drill central hole 5 and the drill connecting part 9 .

[0017] The present inve...

Embodiment 2

[0019] Such as Figure 1-2 As shown, a small-aperture rock-breaking drill bit includes a drill bit connecting portion 9, and the top of the drill bit connecting portion 9 is provided with an outer blade 3 and a central blade 4, and the outer blade 3 is arranged on the outside of the central blade 4 , the outer blade 3 is provided with an outer rock cutting blade 1, the outer rock cutting blade 1 is arranged on the outer edge of the drill bit connecting portion 9, the center blade 4 is provided with a central rock cutting blade 2, the center The rock cutting blades 2 are arranged between the outer rock cutting blades 1, the center of the drill bit connecting portion 9 is provided with a drill bit center hole 5, and the top of the drill bit center hole 5 is provided with a double-sided inclined hole 8, and the double-sided inclined hole 8 The two ends are respectively arranged on the outside of the drill central hole 5 and the drill connecting part 9 .

[0020] The outer rock c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com