Method and system to operate a compressor for an engine

An engine system and compressor technology, applied in combustion engine, engine control, engine components, etc., can solve the problems of turbocharger not providing engine airflow, non-recovery, energy loss, etc., to improve engine air-fuel control, fast speed The effect of using boost pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

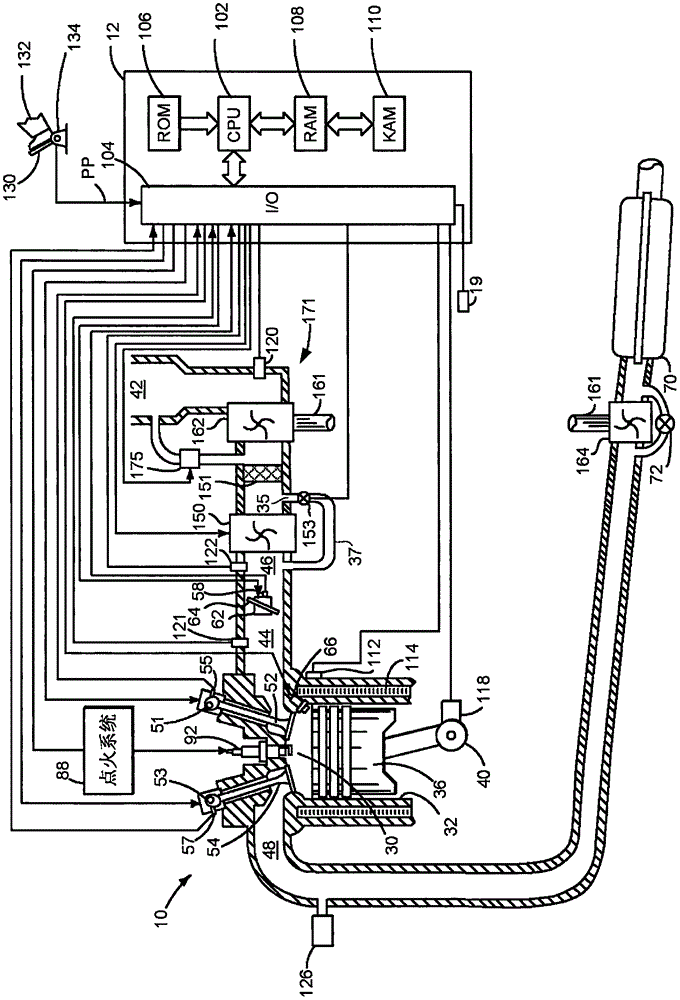

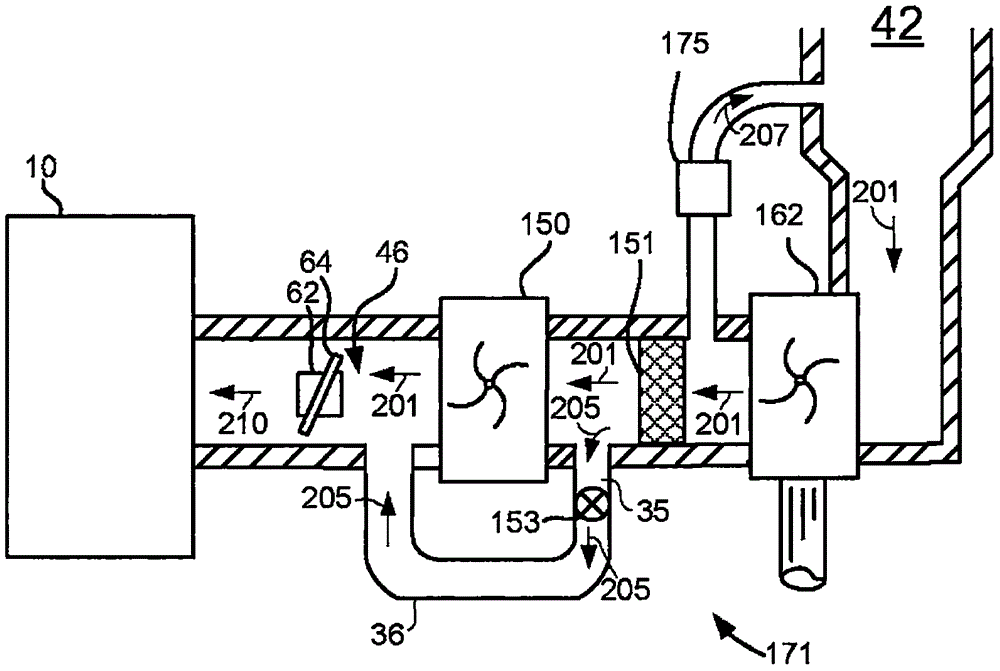

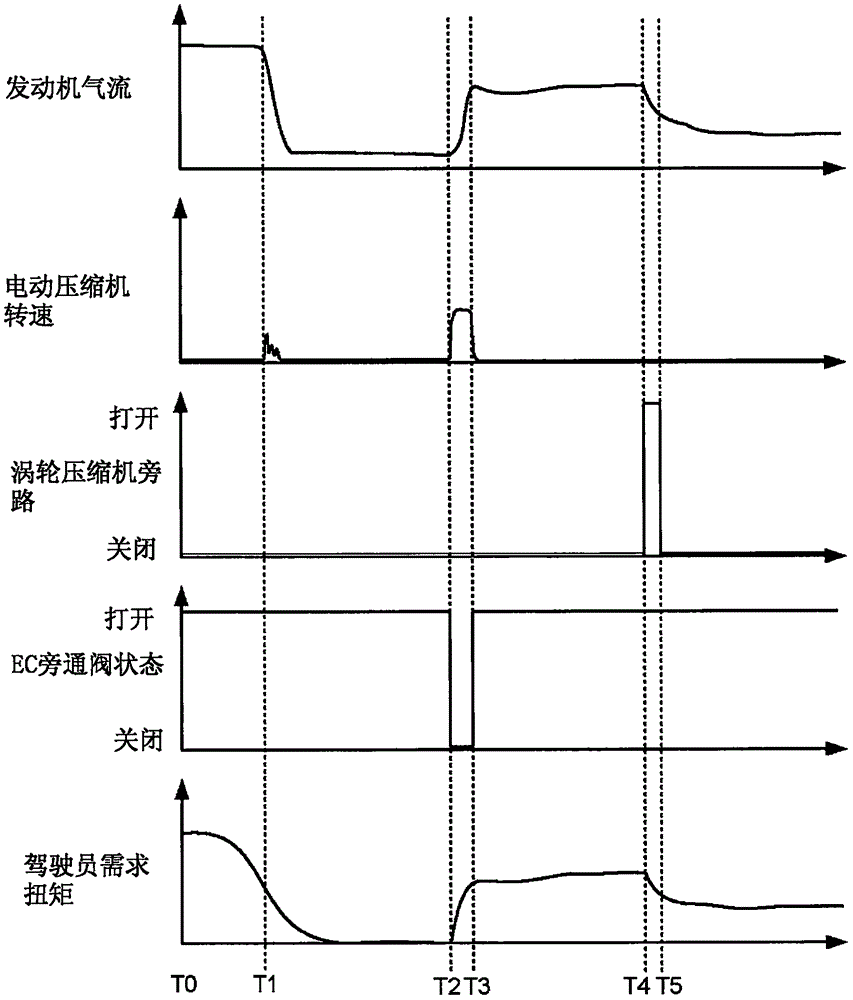

[0011] This instruction relates to the operation of an engine including a turbocharger compressor. A turbocharger compressor may experience oscillations in rotational speed if it is exposed to certain pressure ratios or flow conditions. figure 1 An example engine including two compressors is shown. Pressure oscillations in the engine air intake can be manipulated by figure 2 The electric drive compressor in the arrangement shown is lowered. image 3 An example engine operating sequence for controlling pressure and flow in an engine air intake is shown. Figure 4 A method for operating an engine and reducing the likelihood of compressor surge is shown.

[0012] refer to figure 1 , an internal combustion engine 10 comprising a plurality of cylinders, one cylinder at figure 1 is shown in . Engine 10 includes combustion chamber 30 and cylinder walls 32 with piston 36 positioned therein and connected to crankshaft 40 . Combustion chamber 30 is shown communicating with intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com