Improved self-tapping screw

A technology of self-tapping screws and self-tapping threads, which is applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of low work efficiency, damaged screw heads, unsightly and safe, etc., and achieves simple processing and easy screw head appearance Leakage, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

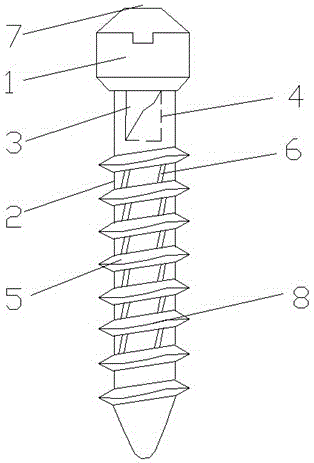

[0014] Such as figure 1 As shown, a kind of improved self-tapping screw of the present invention comprises nut 1, screw rod 2, and the outer edge of screw rod 2 is provided with self-tapping thread 5, is provided with helix and self-tapping thread 5 between adjacent self-tapping threads 5 The assist thread 6 in the opposite direction, the upper end of the screw rod 2 has an inwardly concave screw connecting portion 3, and the lower end of the nut 1 has a protruding nut connecting portion 4, the screw connecting portion 3 is a screw hole with an internal thread, so The nut connection part 4 is a connecting rod with an external thread.

[0015] Preferably, as an embodiment, the nut 1 is provided with a handle 7 .

[0016] Preferably, as another possible embodiment, the outer surface of the screw 2 is provided with a polytetrafluoroethylene anti-seizure layer 8 .

[0017] The self-tapping screw of the present invention is easy to process and easy to assemble. When in use, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com