Flatness detection method

A detection method and flatness technology, applied to measuring devices, instruments, optical devices, etc., can solve the problems of complex structure of detection devices and large detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

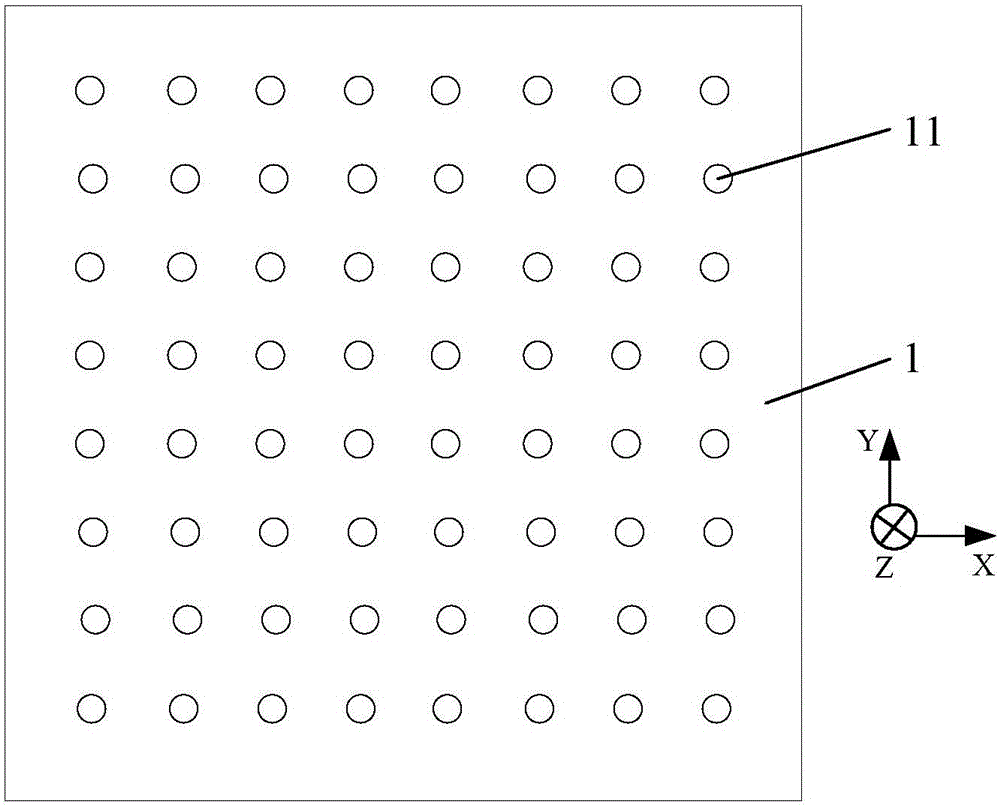

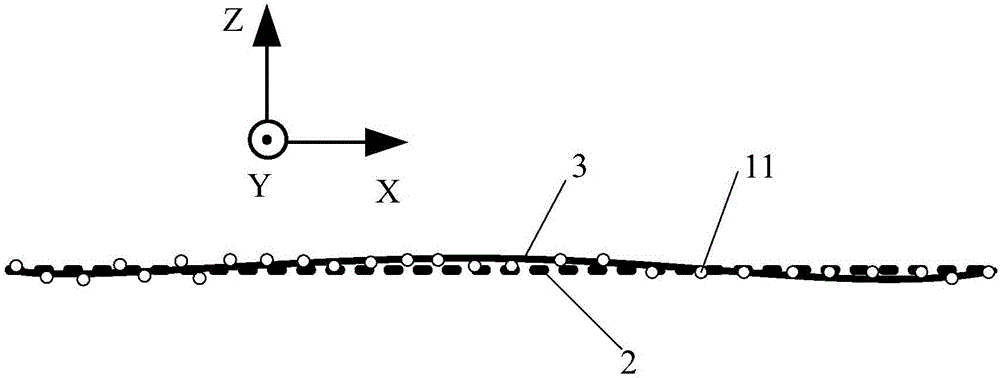

[0021] Such as Figure 1-2 As shown, a flatness detection method of the present invention can carry out flatness detection for all planes, comprising the following steps:

[0022] S1: Select a number of measurement points 11 from the plane 1 to be measured, and detect the three-dimensional coordinates of the selected measurement points 11 through the probe, including X, Y, and Z directions, where Z represents the height; figure 1 As shown, first a three-dimensional coordinate system is established according to the plane 1 to be measured, wherein the X and Y directions are parallel to the plane 1 to be measured, the direction Z is perpendicular to the plane 1 to be measured, and the positive direction is upward. In this embodiment, the measuring points 11 are evenly distributed on the plane 1 to be measured, figure 1 Among them, the number of measuring points 11 is 64, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com