Jack-up type detection method and apparatus for pulling-off force of magnetic hoisting equipment

A lifting equipment and testing device technology, applied in the direction of measuring device, magnetic performance measurement, testing of mechanical parts, etc., can solve problems such as tipping of pull-off force testing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments will be clearly and completely described below in conjunction with the accompanying drawings.

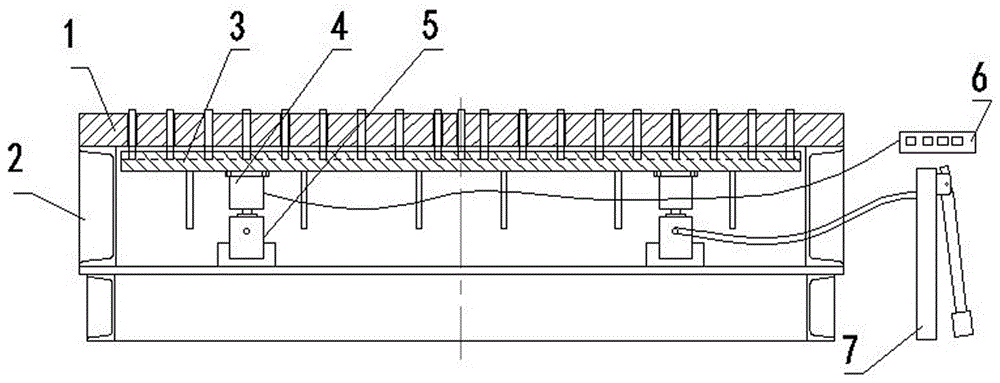

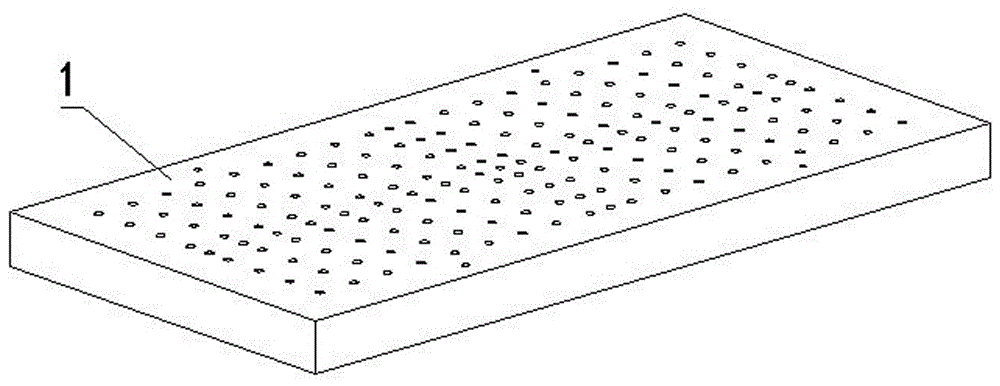

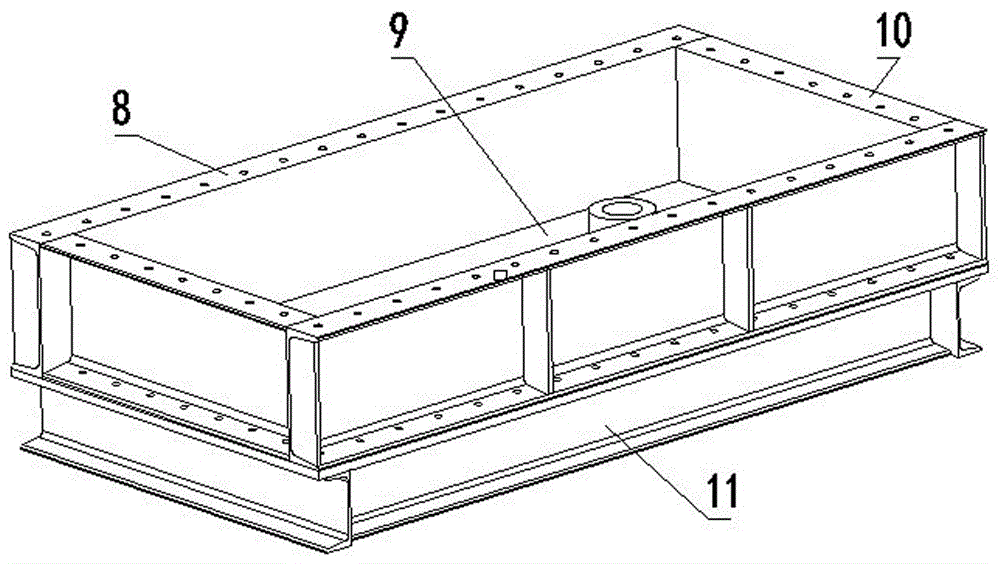

[0017] Explanation of symbols in the drawings: 1 is the platform steel plate; 2 is the box body; 3 is the internal gum; 4 is the pressure sensor; 5 is the hydraulic jack; 6 is the display screen; 7 is the manual pump; 8 is the side plate; 9 is the bottom plate 10 is an end plate; 11 is a foot plate; 12 is an orifice plate; 13 is a baffle plate; 14 is a rib plate; 15 is a push rod;

[0018] Top-open pull-off force detection device such as figure 1 As shown, its top is a platform steel plate 1, and the lower box body 2 has a gum 3 inside, a pressure sensor 4 is below the gum, and a hydraulic jack 5 is below the pressure sensor. In addition, the pressure sensor 4 is connected to the display device 6 through a wire, and the hydraulic jack 5 is connected to an electric or manual pump 7 through a pipeline.

[0019] There are many through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com