Lateral extrusion-push type soil-covering pressing monomer

A soil-covering and single-body technology, which is applied in planting methods, excavation/covering trenches, application, etc., can solve problems such as uncoordinated cooperation between the soil covering device and the suppression wheel, large variation in seed position, uneven suppression pressure, etc., and achieves improved Consistency of plant spacing, uniform distribution of suppression pressure, uniform suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

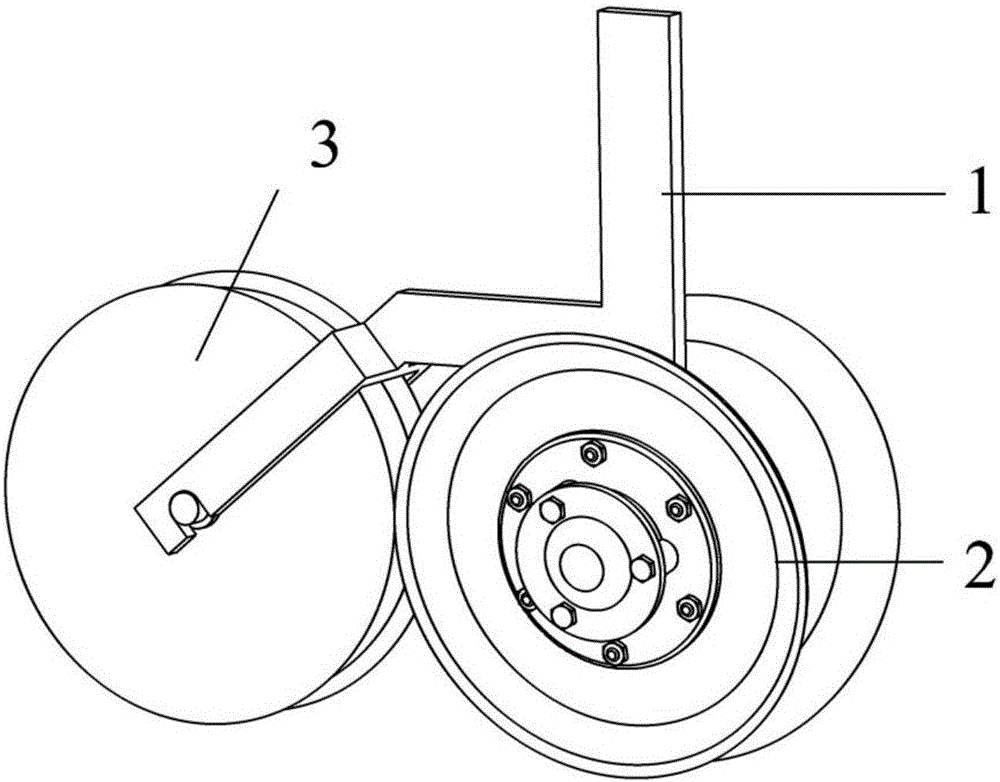

[0025] see Figure 1 to Figure 7 , the present invention is made up of frame 1, earth-covering device 2 and trapezoidal groove suppressing wheel 3, and earth-covering device 2 is installed in frame 1 front, and left and right is symmetrical, and trapezoidal groove suppressing wheel 3 is installed in the rear of frame 1.

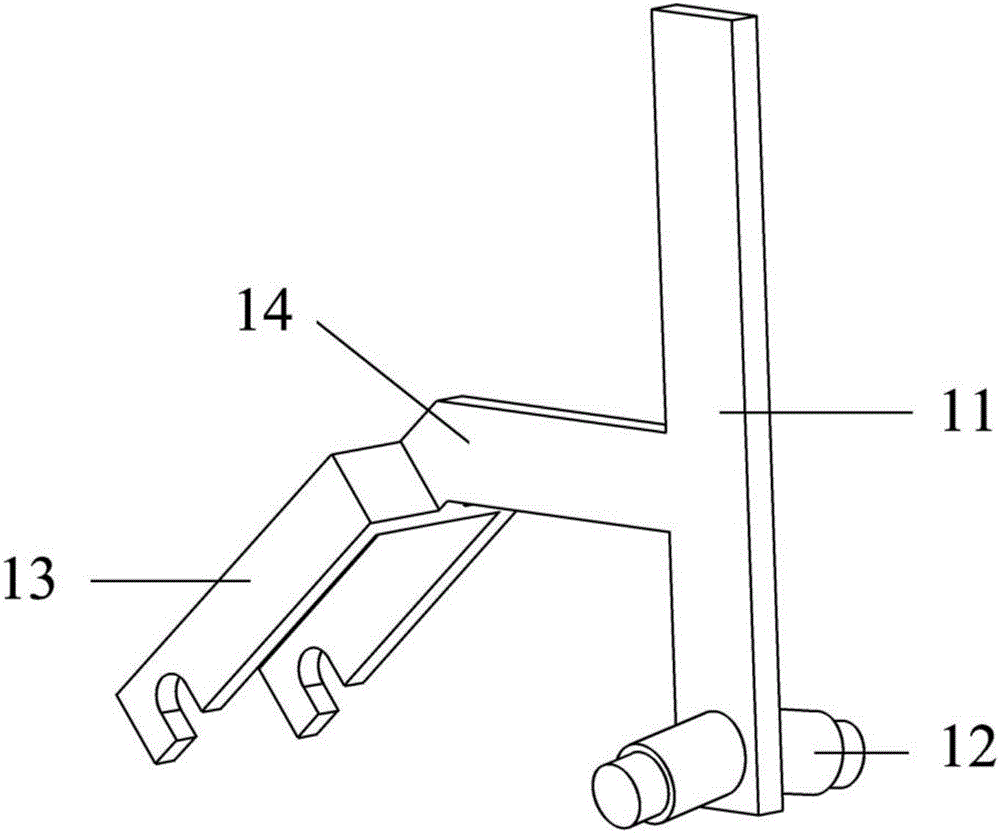

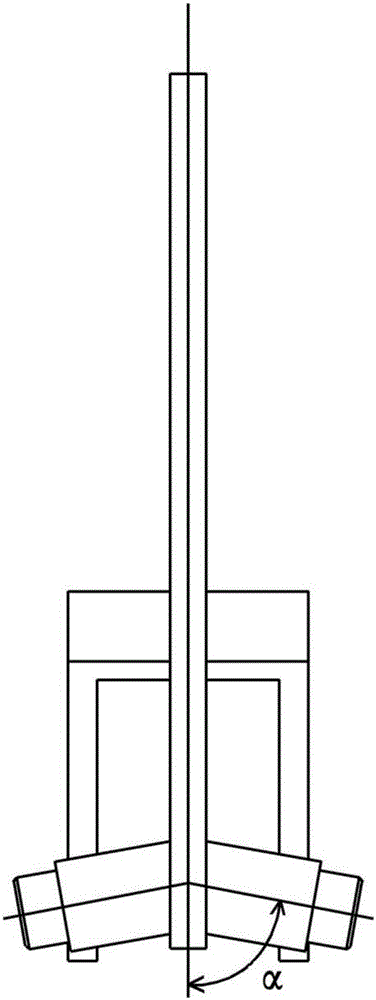

[0026] The frame 1 is left-right symmetrical in the advancing direction, and is made up of a handle 11, a stepped shaft 12, a pressing wheel support 13 and a support plate 14. The frame 1 is made of a plate with a thickness of 4-8mm. Two stepped shafts 12 are respectively fixed on both sides of the handle 11 by welding, and they are symmetrically distributed in the forward direction. On a vertical plane, the angle between the axis of the stepped shaft 12 and the mounting plane of the handle 11 is α, where 2π / 5≤α<π / 2. The stepped shaft 12 has two sections. The section fixed to the installation plane of the handle 11 is the large end of the stepped shaft 12, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com