Renewable large flow filter core

A technology of large flow and filter elements, applied in the field of separation, can solve problems such as process influence, high maintenance costs, damage, etc., and achieve the effects of improving pore structure, prolonging service life, and enhancing pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

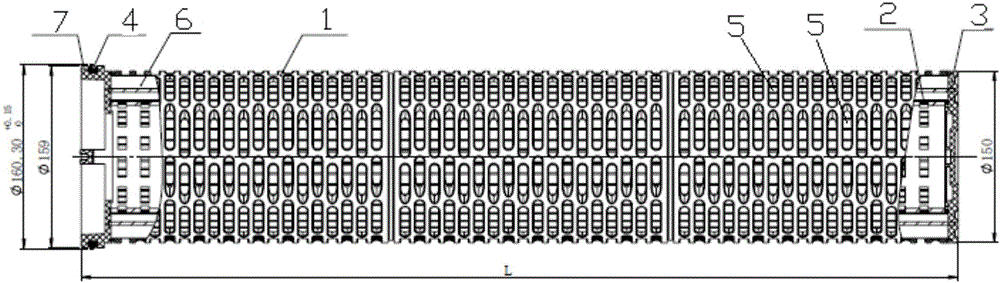

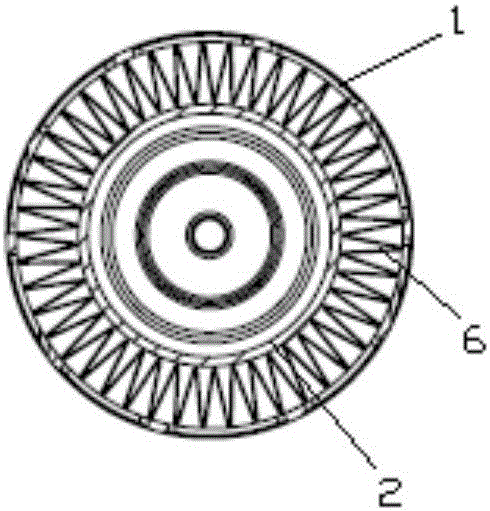

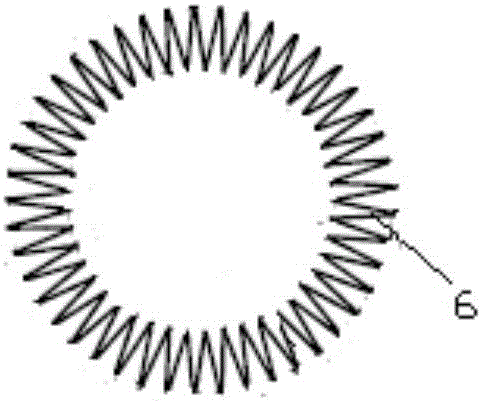

[0021] to combine Figure 1-Figure 3 As shown, a regenerable high-flow filter element has a filter element. One end of the filter element is provided with an upper end cover 7, the other end is provided with a bottom cover 3, and an O-ring 4 is installed on the side edge of the upper end cover 7. The filter element is a fully welded structure without flux addition, which ensures the consistency of the overall material of the filter element and high strength. The filter element includes an inner inner frame 2, an outer outer frame 1, and a filter material 6 arranged between the inner frame 2 and the outer frame 1. The filter material 6 is folded into a corrugated or zigzag structure, which greatly increases the filtration area. More than 20 times that of ordinary filter elements. It can change t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com