Modularized electric field for VOC (Volatile Organic Compound) treatment device

A processing device, a modular technology, applied in gas treatment, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of uneven electric field distribution, poor exhaust gas treatment effect, troublesome assembly operation, etc. The effect of saving trouble and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions and beneficial effects of the present invention will be clearer and more definite by further describing the specific embodiments of the present invention in conjunction with the accompanying drawings.

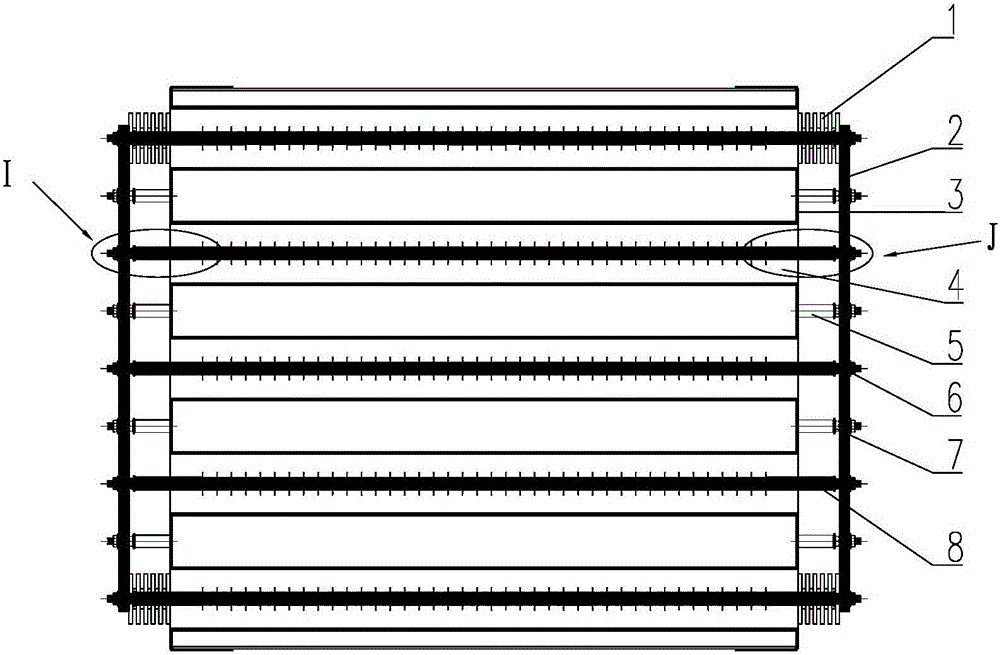

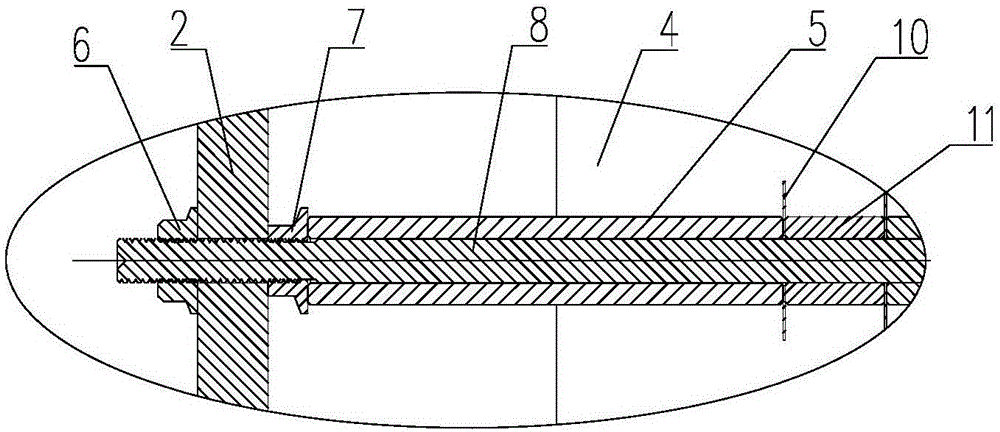

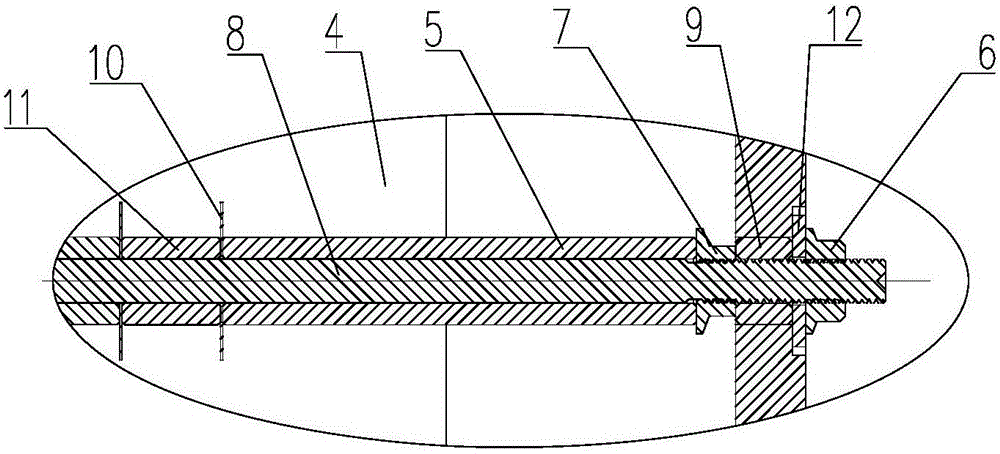

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes two negative electrode plates 3 arranged opposite to each other on the left and right, at least one negative electrode cylinder 4 is vertically fixed between the two negative electrode plates 3, and the position of the negative electrode plate 3 facing the mouth of the negative electrode cylinder 4 is vacant. A coaxial positive pole rod 8 is perforated in each of the negative pole cylinders 4, and at least one coaxial annular positive pole piece 10 is set on each of the positive pole poles 8. There is a gap between the outer circle of the sheet 10 and the inner wall of the negative electrode cylinder 4, a short bushing 11 is placed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com