Intermittent media disperser

A batch type, disperser technology, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve problems such as difficulty in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

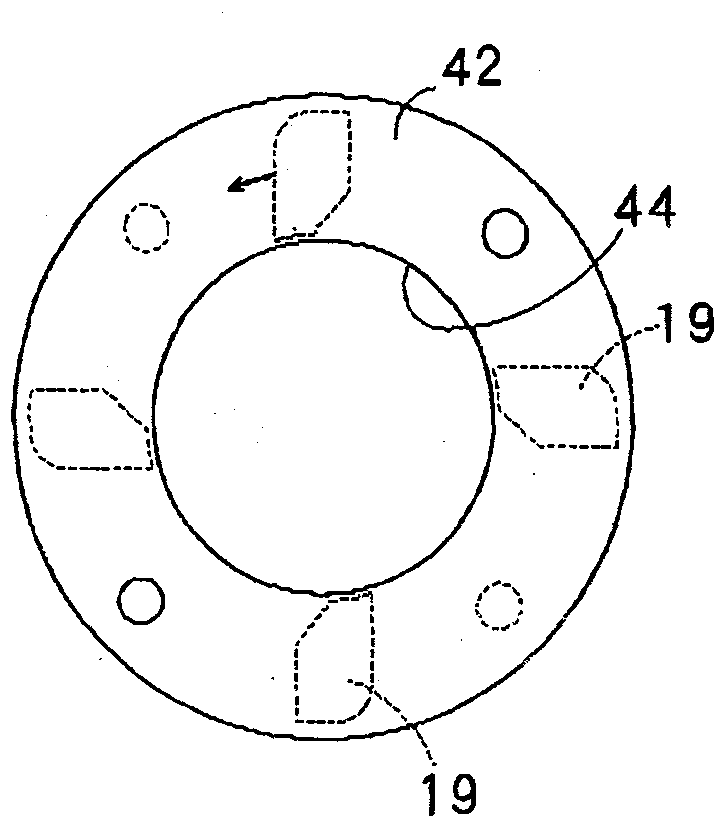

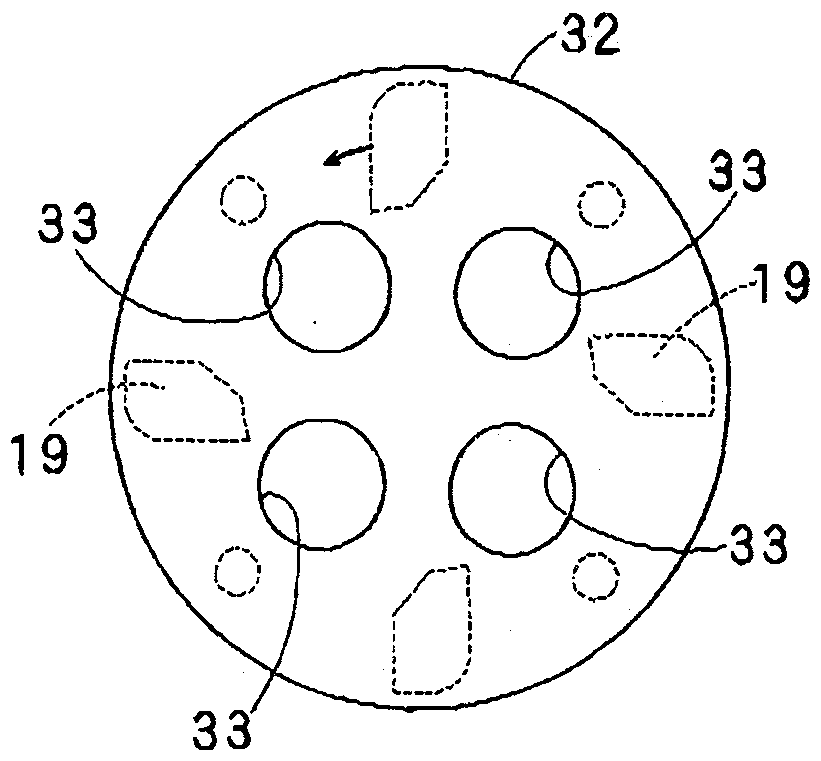

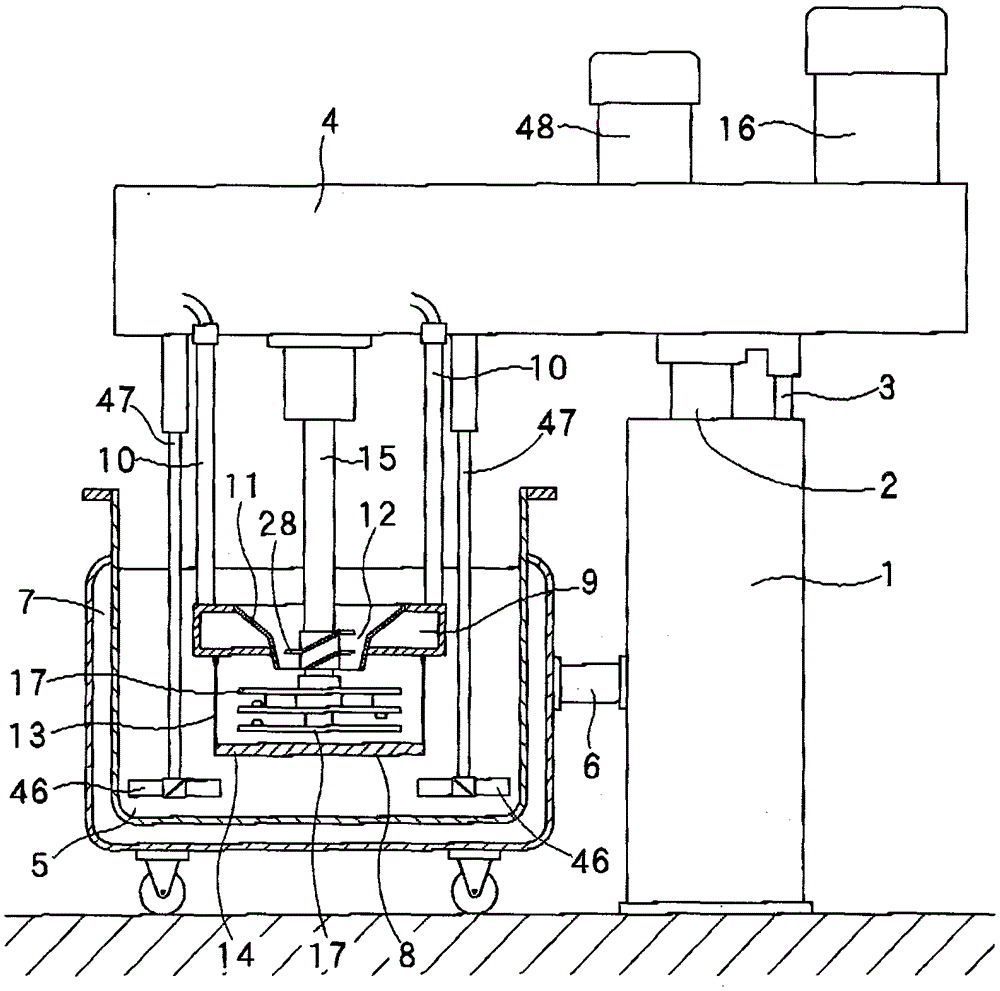

[0018] figure 1 Showing an embodiment of the intermittent medium disperser according to the present invention, a frame 4 is provided above the main body 1 to move up and down by being guided on the guide shaft 3 by the lifting shaft 2 . The tank 5 containing the process material is carried in under the frame 4 and the tank 5 is held at a fixed position by a holder 6 . Around the tank 5, a tank jacket 7 through which a temperature regulating medium such as cooling water flows is provided.

[0019] In the above-mentioned tank 5, a container 8 is placed, and the container 8 accommodates glass, zircon, zirconia, steel, ceramics or other dispersion media (beads), preferably a high specific gravity dispersion media (not shown). The container 8 has an upper casing 9 through which a temperature-regulating medium such as cooling water flows, and is provided below the frame 4 via a water pipe and a support rod 10 that also serves as a flow path of the temperature-regulating medium. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com