Additive manufacturing product and powder treating system and working method thereof

A technology of additive manufacturing and processing system, applied in the direction of manufacturing tools, additive processing, solid material additive processing, etc., can solve the problems of low powder feeding efficiency, affecting the process, large amount of compressed air, etc., to achieve multiple cycles of use , Guarantee production safety, optimize the effect of pipeline control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical features of the present invention will be further described in detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

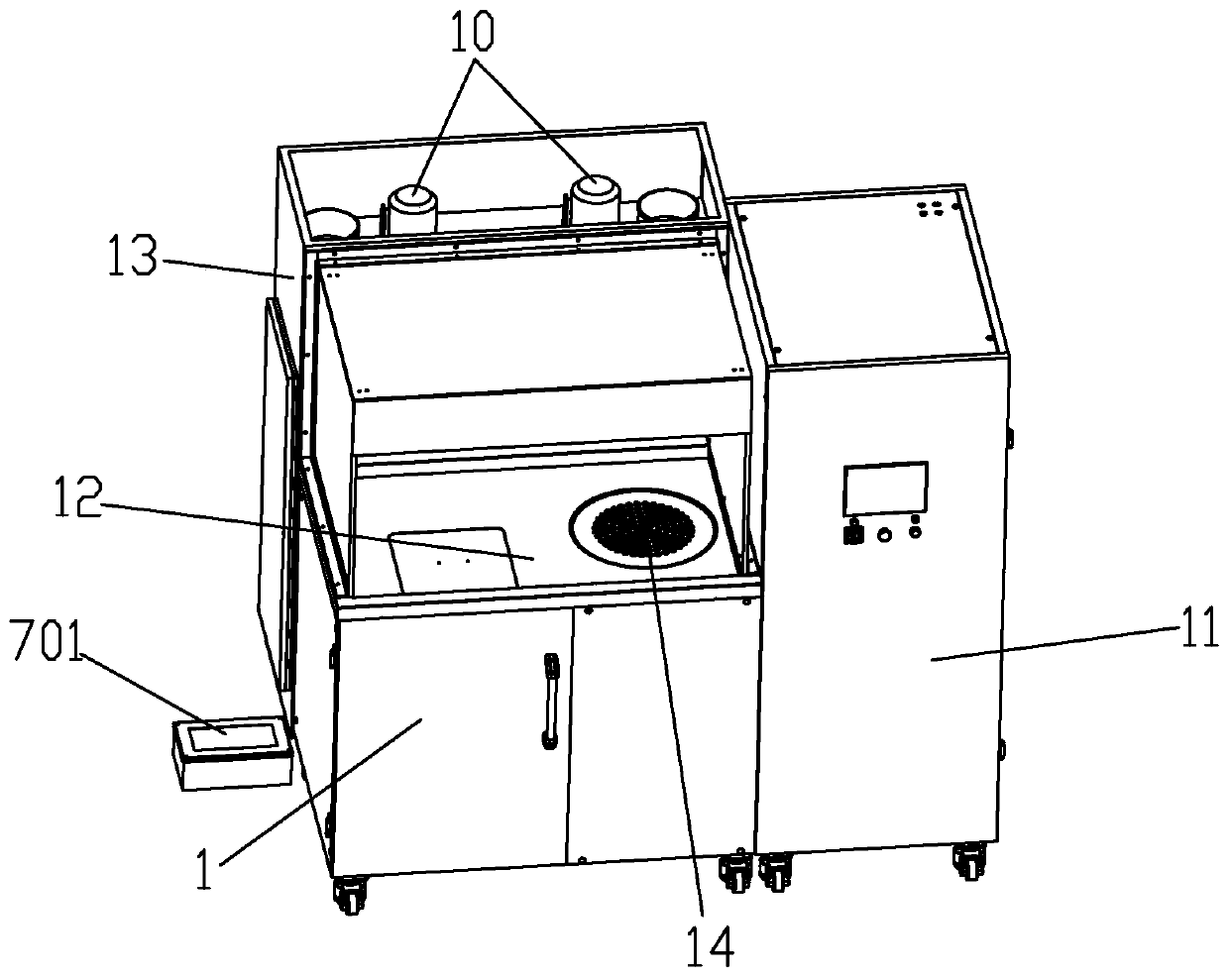

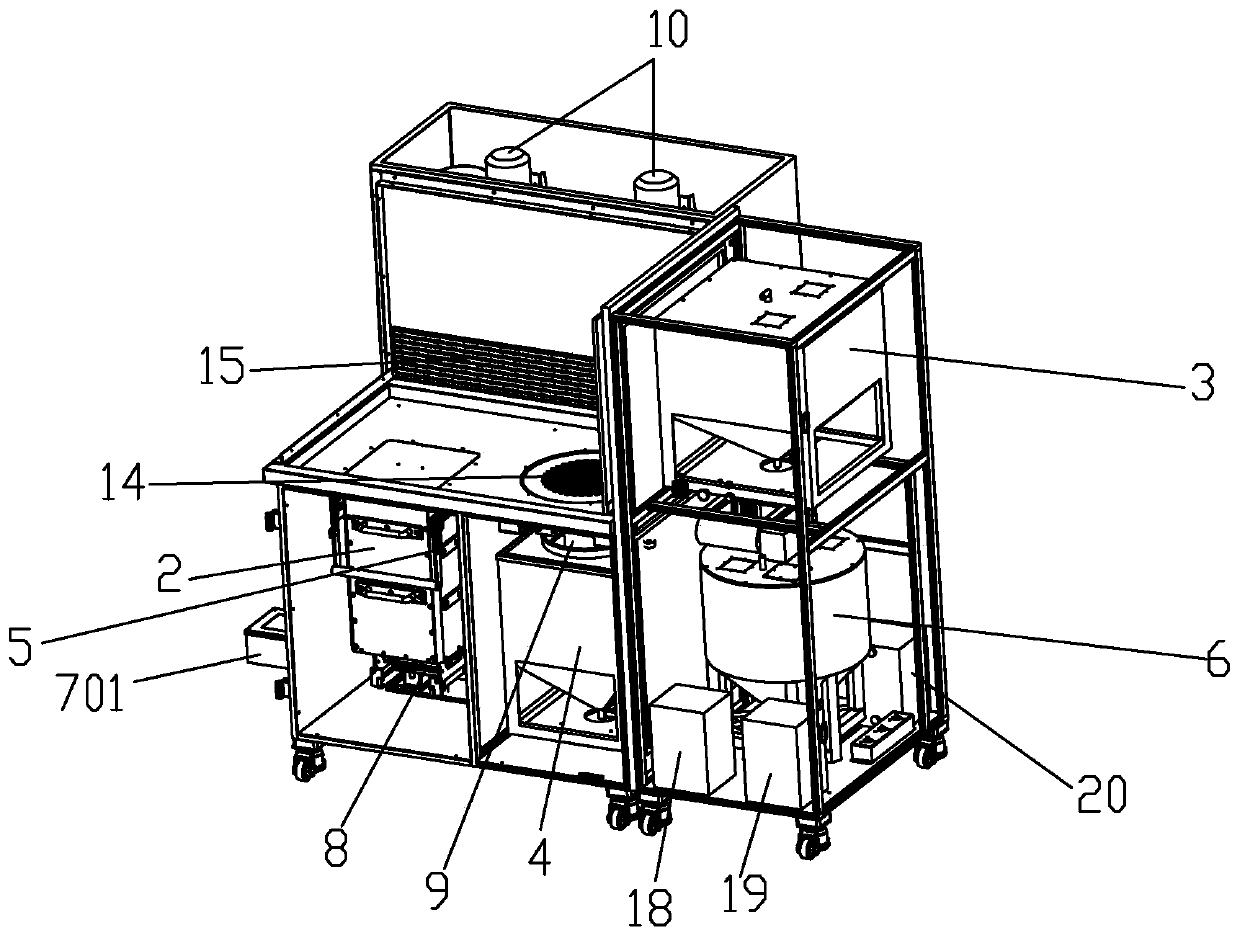

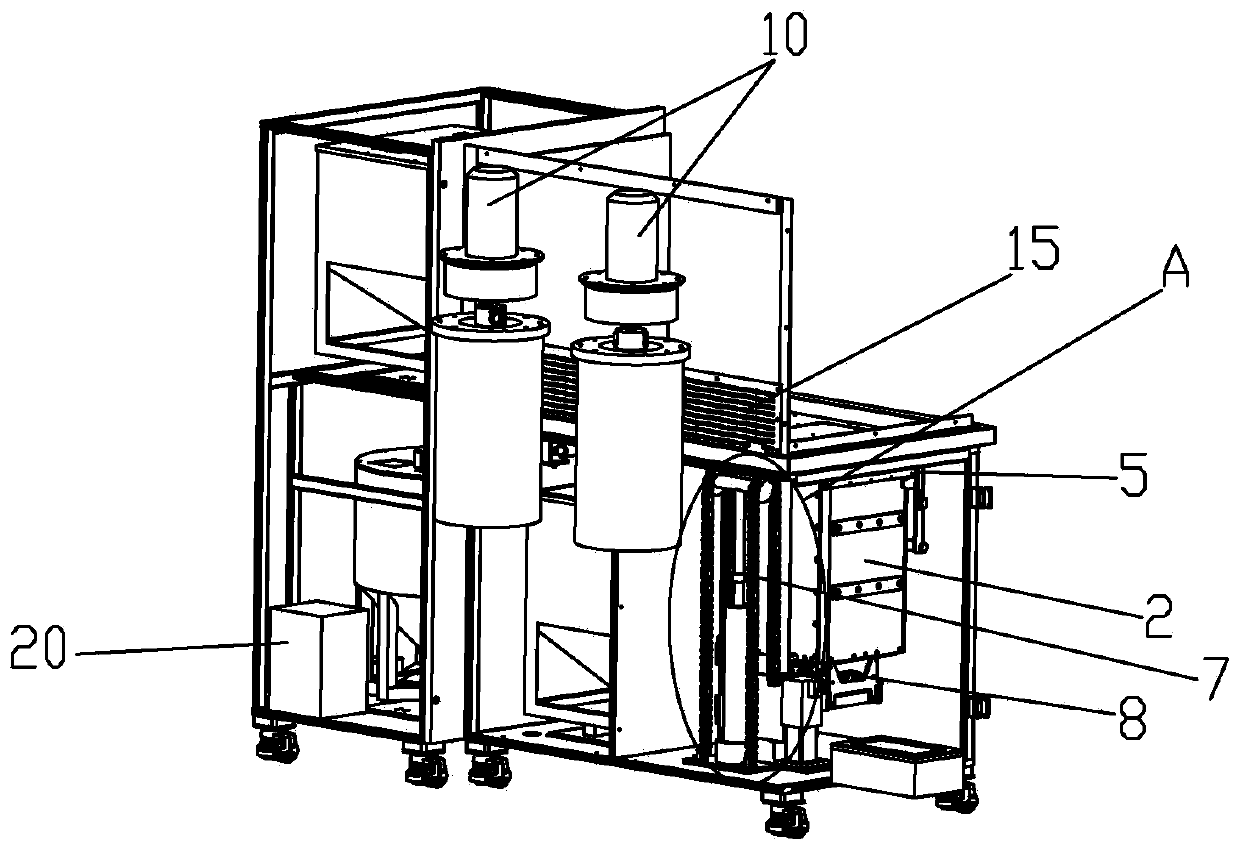

[0038] A product and powder processing system for additive manufacturing, such as figure 1 and Figure 6As shown, a powder cleaning cabinet 1 is included, a powder cleaning platform 12 is arranged in the powder cleaning cabinet 1, and a forming bucket 2 is placed on the lower side of the powder cleaning platform 12, and the forming bucket 2 is equipped with a The molded barrel 2 is transported by the laser sintering molding machine, which contains the products formed after laser sintering and redundant old powder. The old powder remaining after laser sintering is easy to be damp and agglomerated, and must be screened out Qualified old powder must be fully mixed with new powder before it can be reused, otherwise it will seriously affect the surface roughness and strength of the molded p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com