A device and method for pre-cleaning the residual sand in the inner cavity of the cylinder water jacket

A cylinder water jacket and pre-cleaning technology is applied in the field of automobile engine cylinder block casting. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments. In the embodiments of the present invention and in the accompanying drawings, the symbols related to the second, third and fourth are omitted.

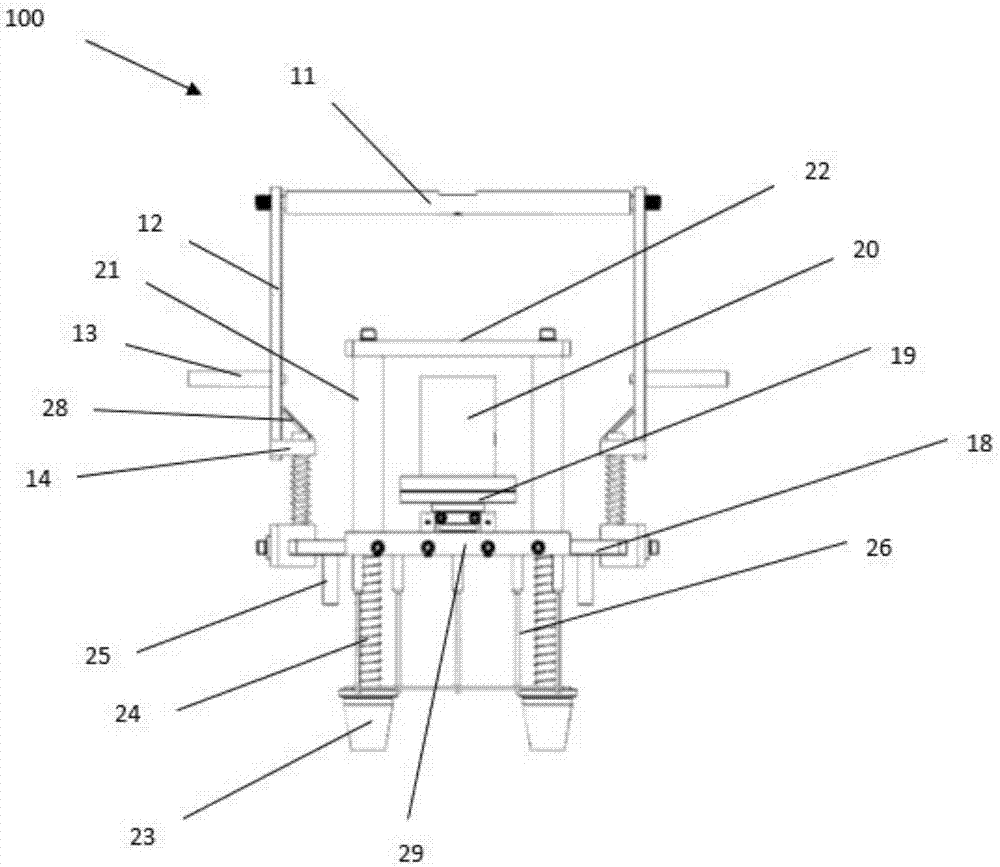

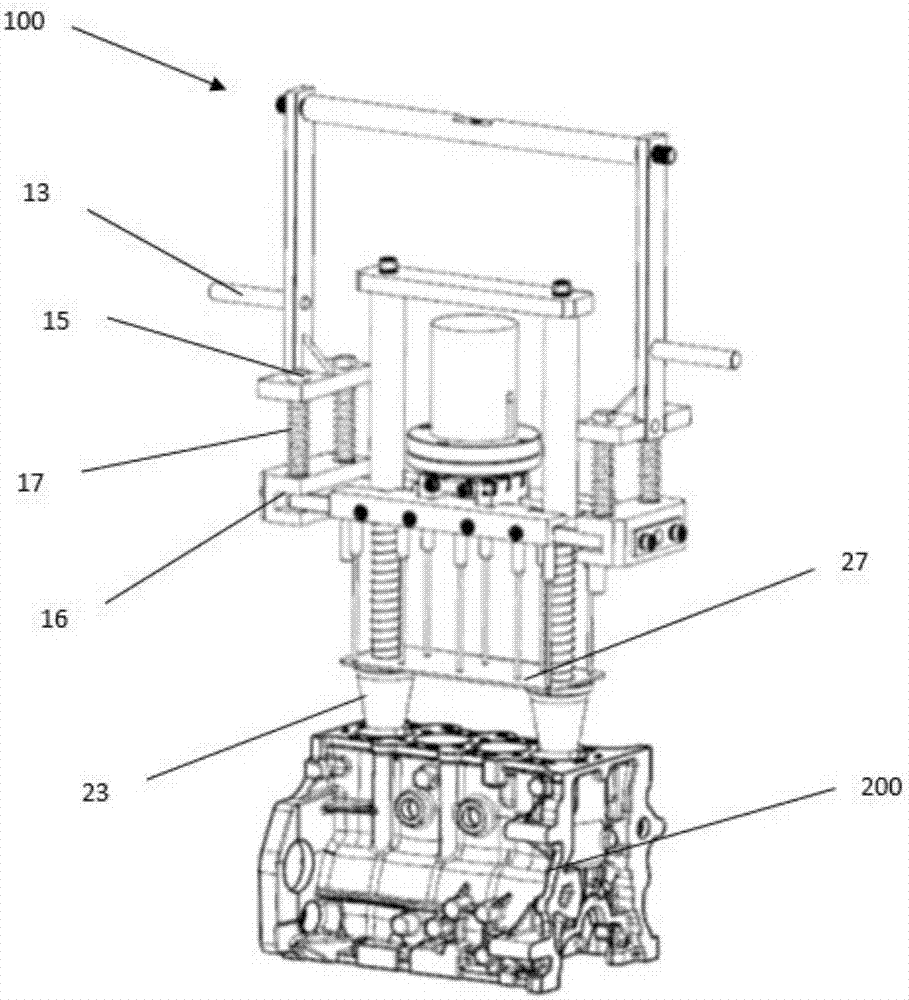

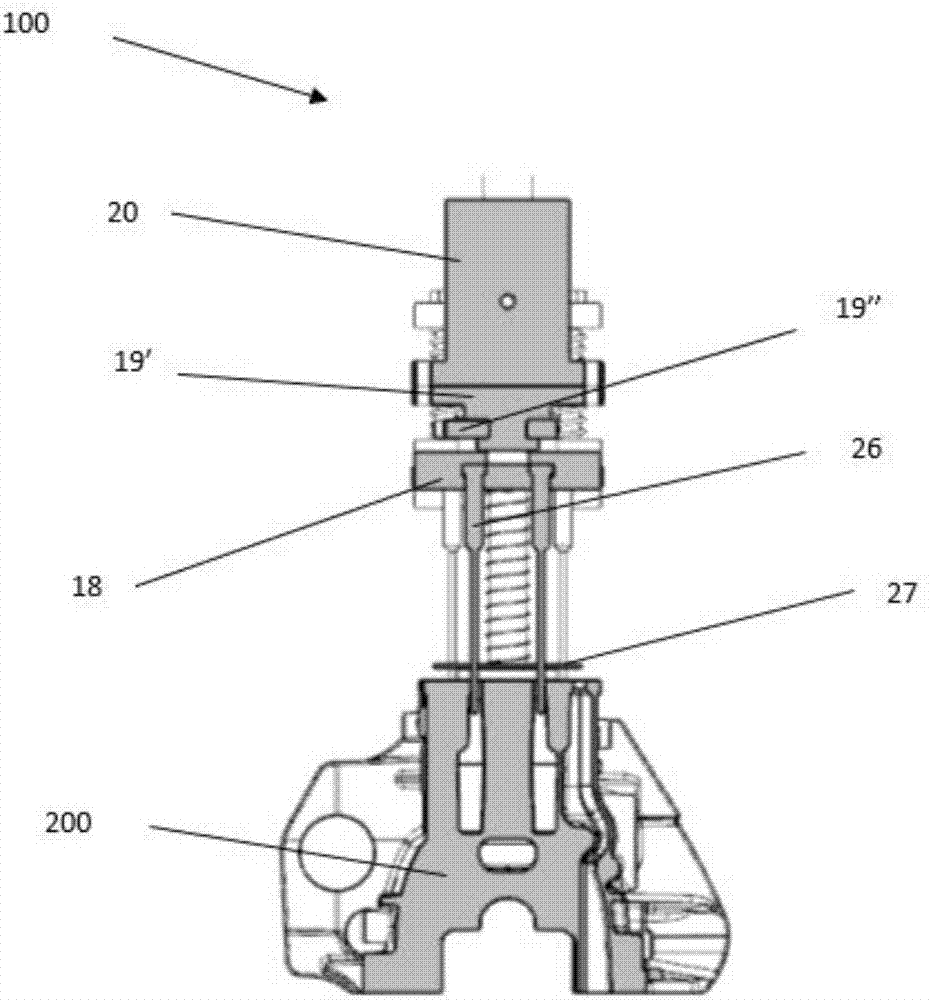

[0034] Such as Figure 1-5As shown, a pre-cleaning device 100 for residual sand in the inner cavity of the cylinder water jacket, the device 100 for residual sand includes: a horizontal beam 11; two ends of the beam 11 are connected with mutually symmetrical The first vertical rod 12 and the second vertical rod; the crossbeam 11 forms a first cavity with the first vertical rod 12 and the second vertical rod; the horizontal direction of the first vertical rod 12 and the second vertical rod is respectively connected with The first handle 13 and the second handle that are mutually symmetrical and extend away from the first cavity; From the end faces of the first vertical rod 12 and the second vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com