Screw locking machine of multi-axis mechanical arm

A technology for locking screw machines and manipulators, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost of heavy manipulators, large size of heavy manipulators, and reduced economic benefits, and achieves light weight, compact structure, and improved performance. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

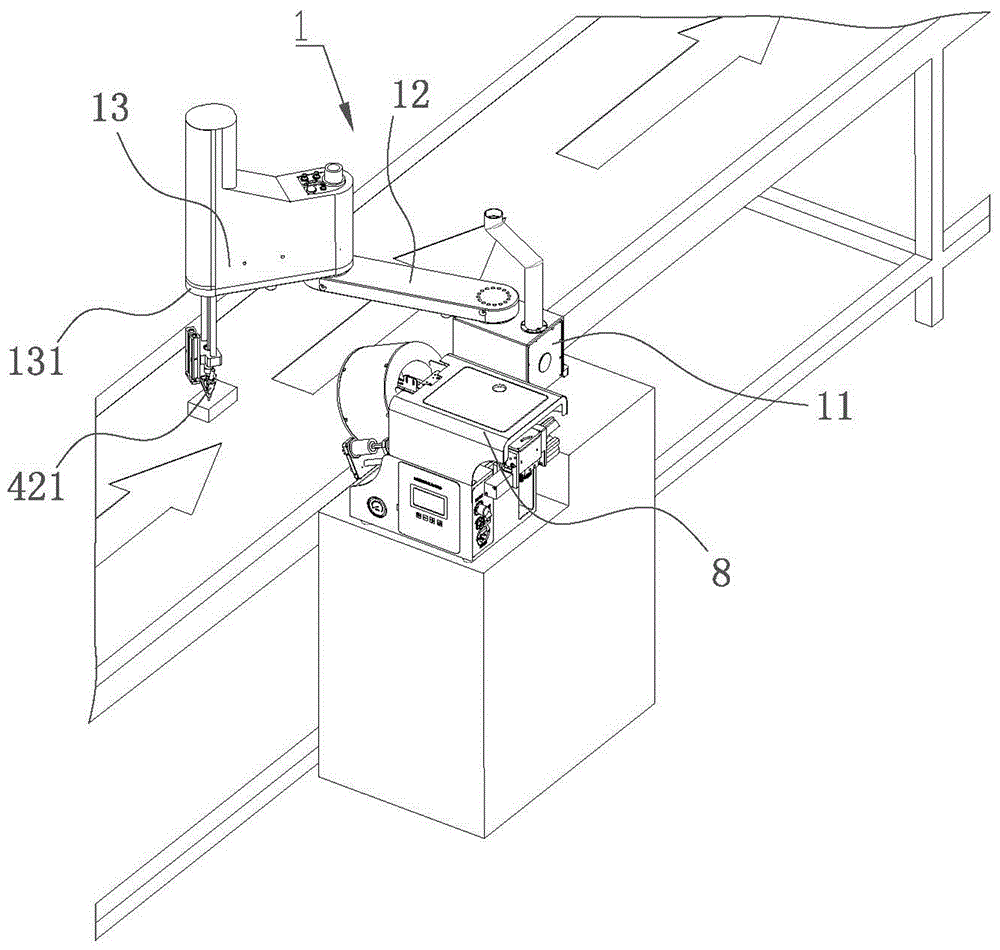

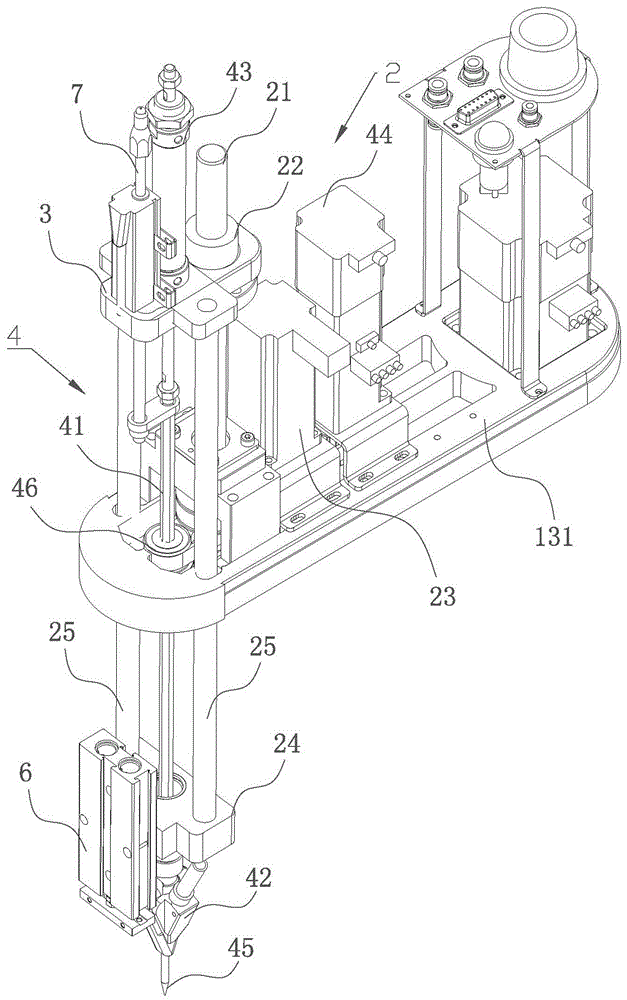

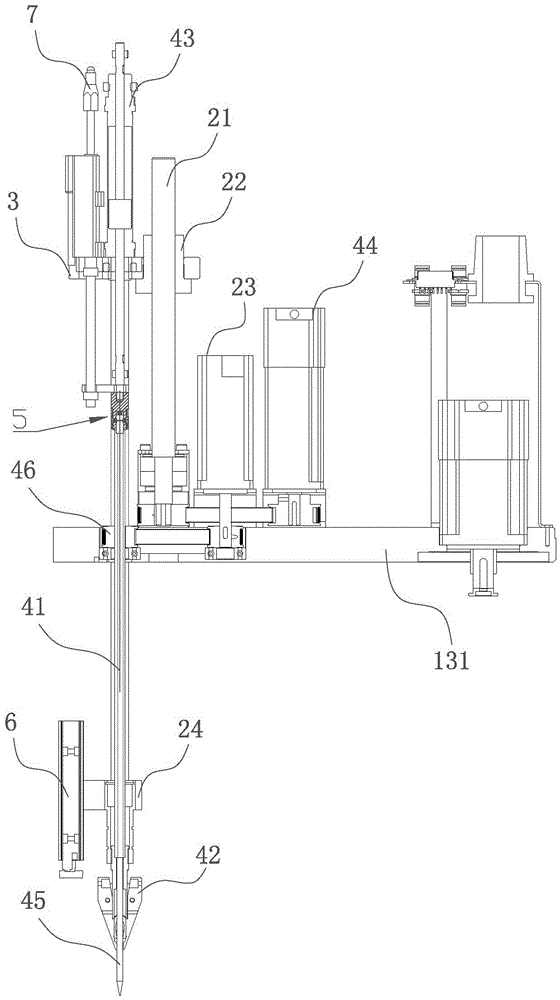

[0036] A kind of multi-axis manipulator locking screw machine of the present embodiment, such as Figure 1 to Figure 3 As shown, it includes a multi-axis manipulator mechanism 1, a Z-axis mechanism 2 and a locking mechanism 4. The multi-axis manipulator mechanism 1 includes a bearing seat 11, a first manipulator arm 12 and a second manipulator arm 13 connected in sequence, and the second manipulator arm 13 Including an arm base 131, the rear end of the arm base 131 is connected to the first mechanical arm 12; the multi-axis manipulator mechanism 1 can be as figure 1 The shown horizontal multi-joint manipulator mechanism (not shown in the figure) or other multi-axis manipulator mechanisms are also within the protection scope of the present invention.

[0037] In this embodiment, the Z-axis mechanism 2 includes a Z-axis screw rod 21 whose lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com