Positioning method for center frame of cutting machine for machining

A technology of cutting machine tool and positioning method, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of locking, elliptical force on the end face of the workpiece, and difficult force, so as to reduce the possibility of contact and reduce the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

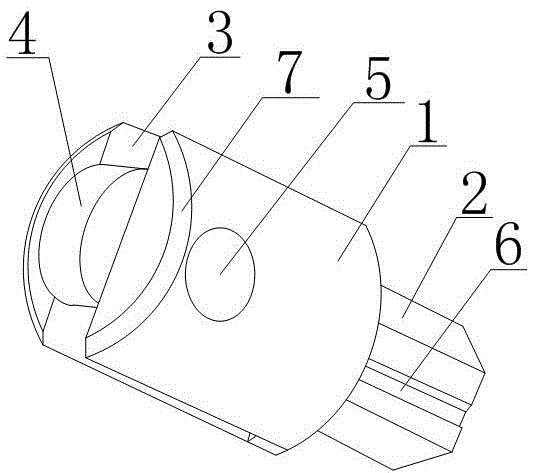

[0018] like figure 1 As shown, a method for positioning the center frame of a machining and cutting machine tool in the present invention includes a top cylinder 1, the top cylinder 1 is cylindrical in shape, and a hexagonal columnar socket 2 is connected to one end surface of the top cylinder 1. A guide groove 6 parallel to the axis of the top cylinder 1 is provided on the piece 2, and a mounting groove 3 is provided on the other end surface of the top cylinder 1, and the end surface is provided with an inverted platform 7, and the inverted platform surrounds the circle where the end surface is located, and the installation groove 3 The two sides on the top tube 1 are parallel to each other and symmetrical about the axis of the top tube 1, and a bearing 5 is installed in the installation groove 3, and the two ends of the bearing 5 are connected to the two sides of the top tube 1 installation groove 3, and A roller 4 is set on the bearing 5, and the radius of the roller 4 is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com