Automatic mechanical clamp

A fixture and mechanical technology, applied in the field of automated mechanical fixtures, can solve problems such as high labor costs and low efficiency of manual loading, and achieve the effects of increased work efficiency, simple and reasonable structure, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

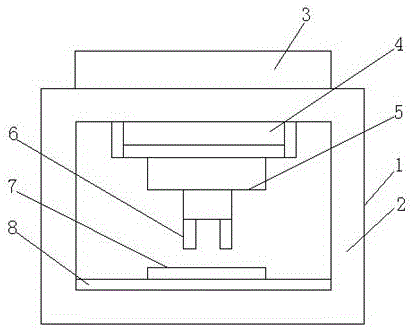

[0014] Such as figure 1 The shown automatic mechanical fixture includes: a fixture body 1; the outer end of the fixture body 1 is provided with a support frame body 2, and the top end of the support frame body 2 is provided with a central controller 3. The upper end of the supporting frame body 2 is provided with a moving tank body 4, and the lower end of the moving tank body 4 is provided with a telescopic arm 5, and the lower end of the telescopic arm 5 is provided with a clamp 6. The inner bottom end is provided with a mobile discharge table 7, and the lower end of the mobile discharge table 7 is provided with a workbench 8;

[0015] Wherein, the central controller 3 is set as a computer host, and its computer host is a single-chip microcomputer, and the central controller 3 is also connected with a remote controller;

[0016] The telescopic arm 5 is configured as a hydraulic telescopic arm;

[0017] The inner wall end of the clamp 6 is also provided with tooth lines.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com