Spanner with adjustable moment of force

A force-adjusting and wrench technology, applied in the directions of wrenches, screwdrivers, manufacturing tools, etc., can solve problems such as inconvenience in use and cost, and achieve the effect of simple structure, satisfying use needs and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

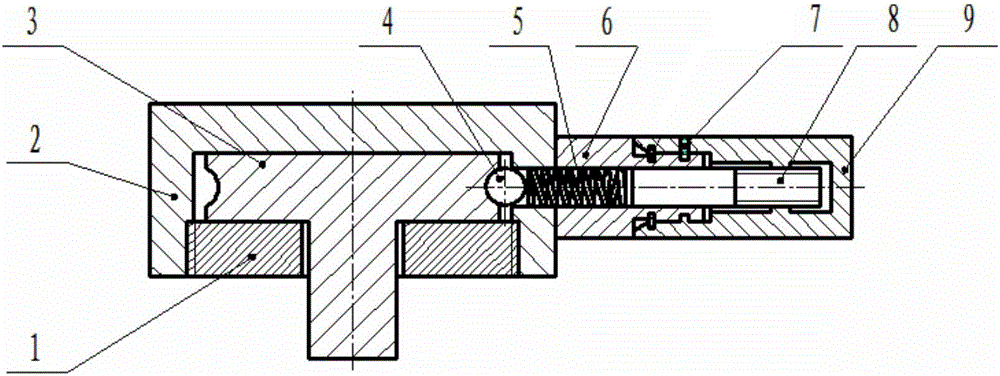

[0021] A kind of adjustable torque wrench of the present invention, as figure 1 As shown, it includes housing 2, lower baffle 1, wrench body 3, handle, ball 4, spring 5, and adjusting screw 8;

[0022] The housing 2 is a cylindrical member with an open lower end, the inner wall of the opening port of the housing 2 is processed with connecting threads, and the side wall of the housing 2 is provided with a ball passing hole;

[0023] The lower baffle 1 is a disc-shaped structure whose side wall is processed with an external thread matching the thread of the opening port of the shell 2, and the center of the lower baffle 1 is provided with a wrench hole;

[0024] The upper end of the wrench body 3 is a cylindrical section whose outer diameter matches the inner diameter of the inner cavity of the housing 2. The side wall of the cylindrical section is provided with hemispherical grooves uniformly distributed around the circumference, and a wrench rod extends vertically downward fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com