Membrane taking equipment

A kind of equipment and technology of film suction board, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of flexible film position error on the film platform, difficult operation of flexible film, easy film collapse, etc., to achieve convenient correction and precision The effect of high degree and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

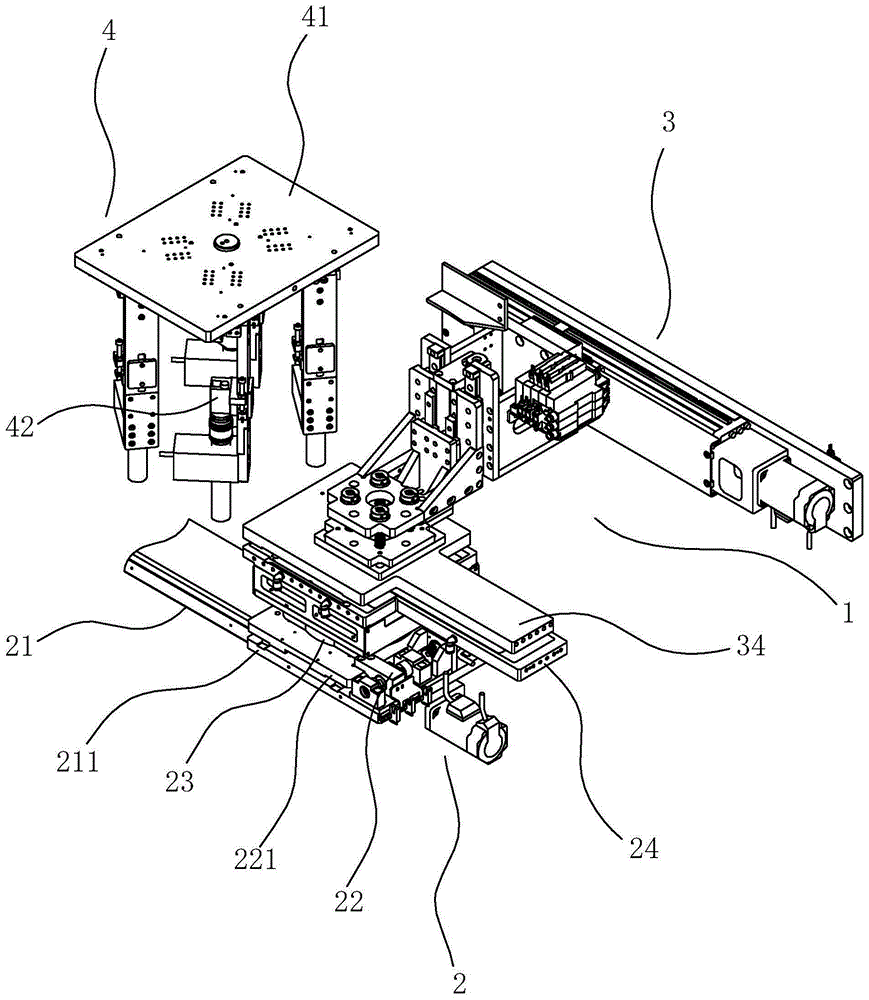

[0043] A film taking device 1, comprising: a correction device 2, a film suction device 3 arranged on the periphery of the correction device 2, a photographing device 4 positioned at one end of the film suction device 3, a feed bin positioned at the front end of the photographing device 4 (not shown in the figure) ), and a PLC program control unit (not shown in the figure).

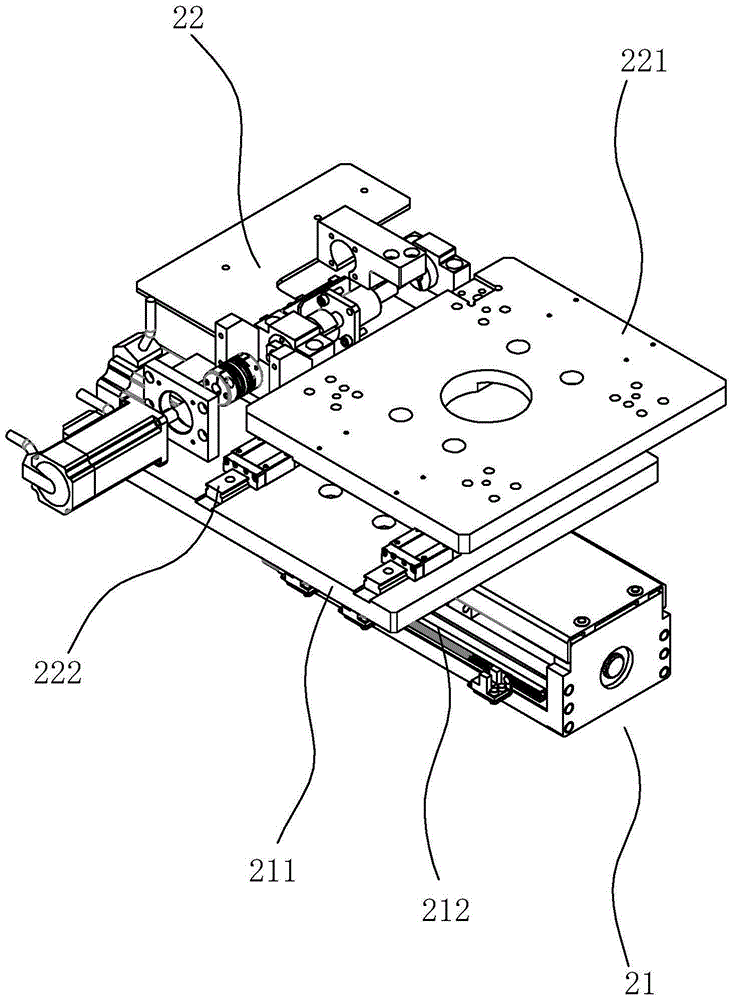

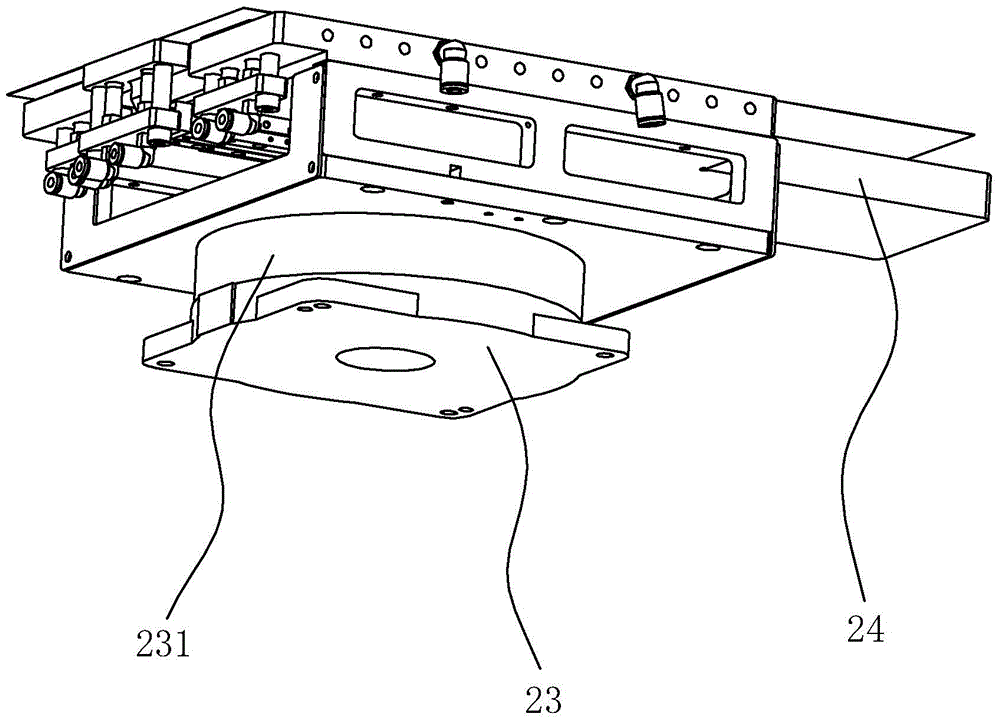

[0044] The correction device 2 includes a first horizontal linear module 21, a vertical linear module 22 fixed to the sliding platform 211 of the first horizontal linear module 21, an angle adjustment mechanism 23 fixed to the vertical linear module 22 moving platform 221, and fixed to the The lower suction film plate 24 of the movable end 231 of the angle ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com