Tower crane lifting hook anti-swing control system and method

A control system, motor drive control technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of difficult operation, low work efficiency, inaccurate positioning, etc., and achieve stable rotation and work efficiency. Enhanced, Harmful Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] The tower crane hook anti-swing control scheme of the present invention uses a detection device to detect the acceleration of the hook in real time, and obtains the control acceleration by establishing a rotation acceleration and deceleration control model algorithm to adjust the rotation speed of the hook to achieve anti-swing protection for the hook. swing control.

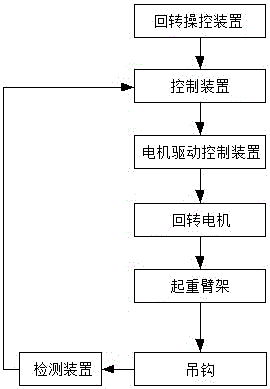

[0021] Such as figure 1 As shown, the present invention includes a suspension hook installed on a boom frame, a control device, a slewing control device connected to the control device, a motor drive control device connected to a slewing motor, and a detection device.

[0022] Among them, the jib frame is used to carry the heavy load; the hook is used to hang the heavy load; the slewing control device is used to give the slewing operation or stop information to the control device; the control device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com