A kind of halo material and preparation method, electronic light guiding device

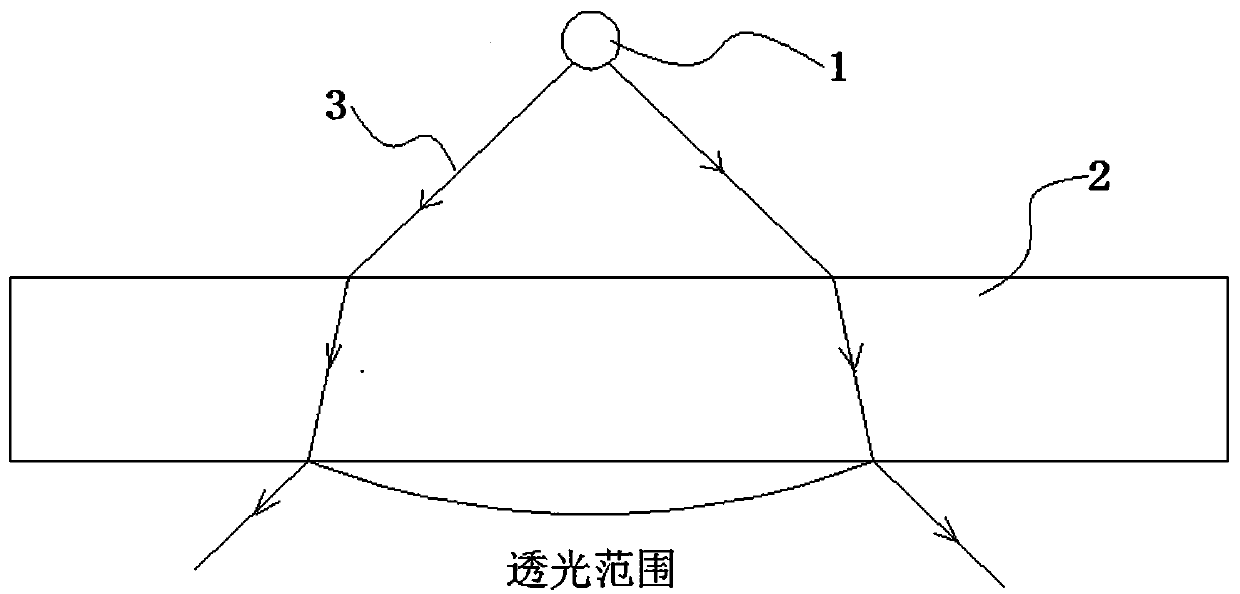

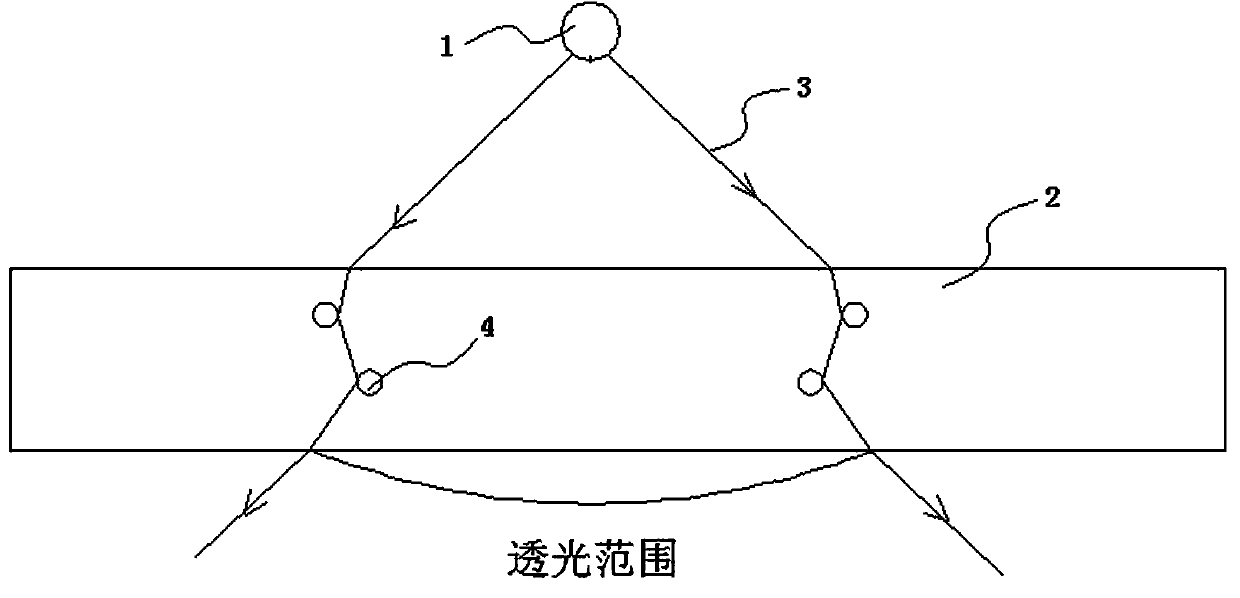

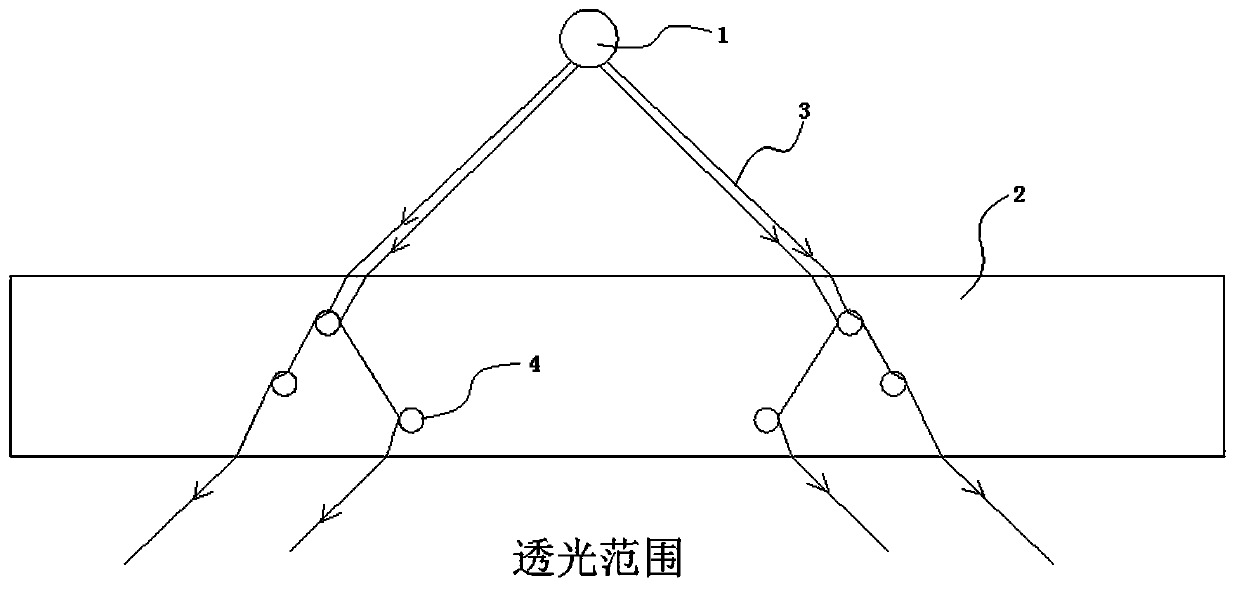

A technology of light additives and molecular weight, applied in optics, optical components, instruments, etc., can solve the problems of brightness attenuation, high light transmittance, inability to achieve surface luminescence, etc., and achieve the effect of improving haze and increasing the range of light transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of halo material described in the present embodiment, the steps are:

[0025] 1) Weigh the raw materials in proportion, dry the PC resin at 75°C for 3-4 hours; mix the optical aid, compatibilizer and PC resin evenly in a high-speed mixer, and the stirring speed is 3000-4000r / min. High-speed stirring and diffusion, the light additive can be evenly dispersed in the PC substrate, so as to ensure a more uniform light dispersion.

[0026] 2) The mixed material is extruded and granulated by a screw extruder to obtain a light diffusing material. The screw aspect ratio is 37-45. The temperature in zone one: 175-185°C, the temperature in zone two: 185-195°C, the temperature in zone three: 205-215°C, the temperature in zone four: 215-225°C, the temperature in zone five: 205-215°C, the temperature in zone six: 195-205°C, the rotational speed of the screw is 320r / min.

[0027] The electronic light guide device prepared by using the above-mentioned halo mat...

Embodiment 1-3

[0029] Prepare the halo material with the formula ratio in Table 1. The preparation method is to dry the PC resin at 75°C for 3 hours; mix the optical aid, compatibilizer and PC resin evenly in a high-speed mixer, and the stirring speed is 3500r / min. The mixed material is extruded and granulated by a screw extruder to obtain a light diffusing material. The length-to-diameter ratio of the screw is 40, the temperature of the first zone: 175-185°C, the temperature of the second zone: 185-195°C, the temperature of the third zone: 205-215°C, the temperature of the fourth zone: 215-225°C, the temperature of the fifth zone: 205- 215°C, six zone temperature: 195-205°C, screw speed 320r / min.

[0030] The particle size of the polymethyltriethoxysilane is 5 μm, and the molecular weight is 12000. The light transmittance, haze and appearance of the halo material are tested and observed, and the results are shown in Table 1.

[0031] Light transmittance refers to the percentage of the lu...

Embodiment 4-6

[0035] With the formulation ratio in Table 2, the halo material is prepared, the preparation method is the same as in Example 1, wherein the polyphenyltriethoxysilane has a particle diameter of 8 μm, a molecular weight of 12000, and the light transmittance of the halo material , haze and appearance were tested and observed, and the results are shown in Table 2.

[0036] The formula ratio of table 2 embodiment 4-6 and corresponding performance test result

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com