Production method of cordyceps sinensis fruit wine

The technology of a kind of Cordyceps sinensis and its production method is applied in the production of fruit wine and the field of production of Cordyceps sinensis fruit wine, which can solve the problems of neutral pH of Cordyceps nutrient solution, high sulfur dioxide content, easy loss of color and aroma, etc., so as to avoid the loss of color and aroma , reduced content, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

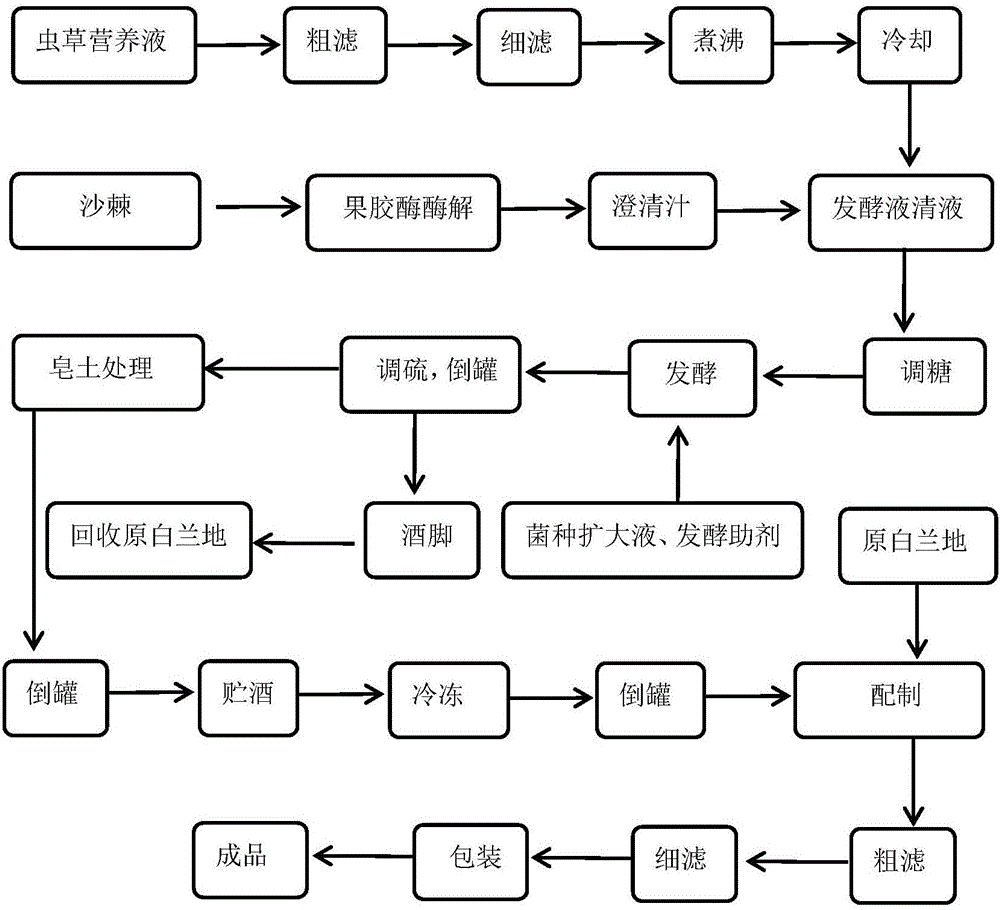

Image

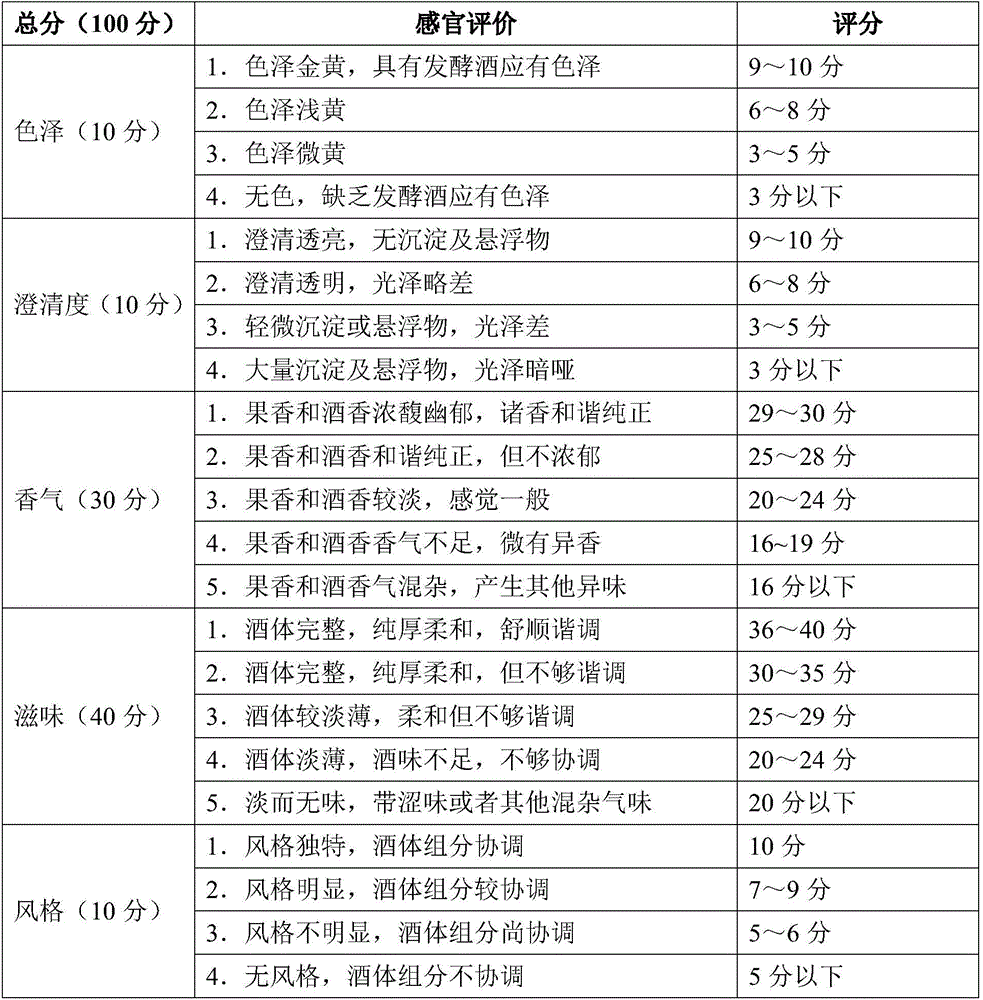

Examples

Embodiment 1

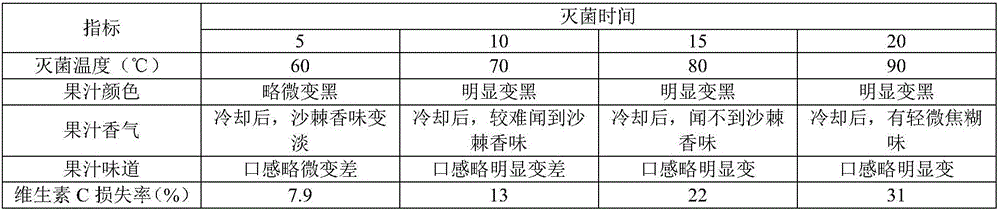

[0035] (1) Filtration: Boil after filtering the Cordyceps sinensis nutrient solution (substratum) separated by fermentation of the Cordyceps sinensis bacterium, remove floating objects on the liquid surface, cool to normal temperature, and stand-by;

[0036] (2) Juice extraction: enzymolyze the seabuckthorn juice with HC pectinase, then siphon the supernatant, precipitate and filter, take out the seabuckthorn juice and mix it with the supernatant;

[0037] (3) Mixing: mix the Cordyceps nutrient solution and seabuckthorn juice in a weight ratio of 2:1, and adjust the pH to 3.2;

[0038] (4) Sugar adjustment: adjust the total sugar content to 200g / L;

[0039] (5) Fermentation: expand the culture of yeast, and add FN502 fermentation aid to ferment;

[0040] (6) Sulfur adjustment: After fermenting to residual sugar < 4g / L, pour the tank, quickly separate the wine legs, squeeze the wine legs, distill the wet residue to recover the original brandy, and then add 6% sulfurous acid so...

Embodiment 2

[0052] (1) Filtration: Boil after filtering the Cordyceps sinensis nutrient solution (substratum) isolated after fermentation by the Cordyceps sinensis bacterium, remove floating objects on the liquid surface, cool to normal temperature, and stand-by;

[0053] (2) Juice: the seabuckthorn juice is enzymolyzed with HC pectinase, then the supernatant is sucked by siphon, and the seabuckthorn juice is taken out after sedimentation and pressure filtration and mixed with the supernatant;

[0054] (3) Mixing: mix the Cordyceps nutrient solution and seabuckthorn juice in a weight ratio of 4:1, and adjust the pH to 3.4;

[0055] (4) Sugar adjustment: adjust the total sugar content to 210g / L;

[0056] (5) Fermentation: expand the culture of yeast, and add FN502 fermentation aid to ferment;

[0057] (6) Sulfur adjustment: After fermenting to residual sugar < 4g / L, pour the tank, quickly separate the wine legs, squeeze the wine legs, distill the wet residue to recover the original brandy...

Embodiment 3

[0069] (1) Filtration: Boil after filtering the Cordyceps sinensis nutrient solution (substratum) separated by fermentation of the Cordyceps sinensis bacterium, remove floating objects on the liquid surface, cool to normal temperature, and stand-by;

[0070] (2) Juice extraction: enzymolyze the seabuckthorn juice with HC pectinase, then siphon the supernatant, precipitate and filter, take out the seabuckthorn juice and mix it with the supernatant;

[0071] (3) Mixing: mix the Cordyceps nutrient solution and seabuckthorn juice in a weight ratio of 6:1, and adjust the pH to 3.6;

[0072] (4) Sugar adjustment: adjust the total sugar content to 220g / L;

[0073] (5) Fermentation: expand the culture of yeast, and add FN502 fermentation aid to ferment;

[0074] (6) Sulfur adjustment: After fermenting to residual sugar < 4g / L, pour the tank, quickly separate the wine legs, squeeze the wine legs, distill the wet residue to recover the original brandy, and then add 6% sulfurous acid so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com