Externally suspended formwork, assisting device and construction method for oblique pile construction

A technology of auxiliary device and construction method, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of unsatisfactory fastening effect between external formwork and pile opening, difficult concrete pouring process, poor consistency of inclined piles, etc. The effect of overcoming unstable position, obvious tightening effect and reasonable pouring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

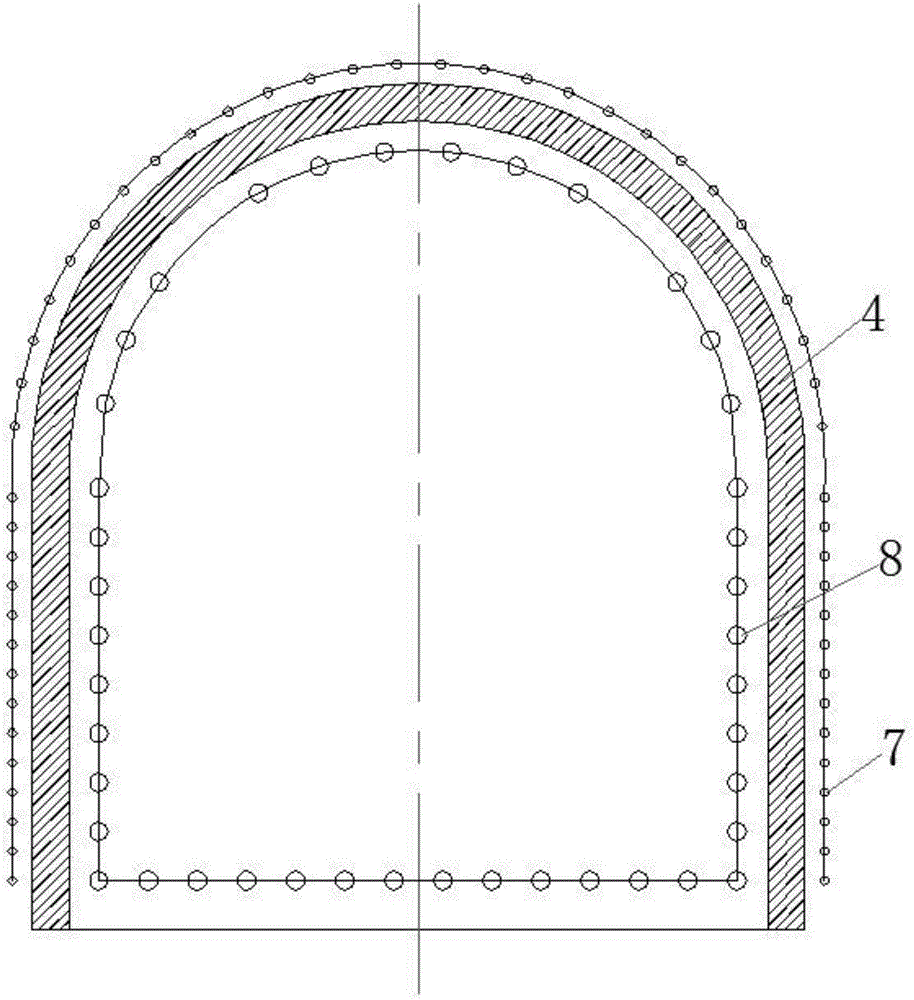

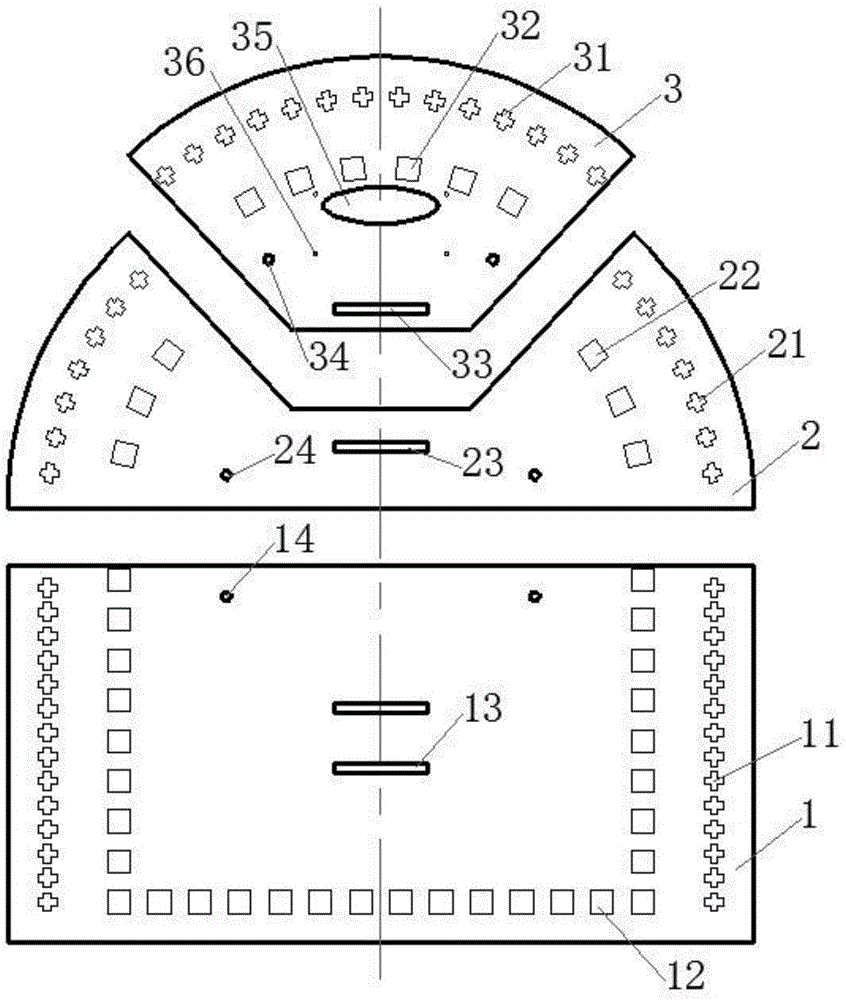

[0057] like Figure 1 to Figure 8 As shown, an external formwork and auxiliary device for inclined pile construction, the external formwork includes a bottom formwork 1, a middle formwork 2 and a top formwork 3 that cooperate with each other, the bottom formwork 1 is rectangular, and the bottom formwork 1 The first outer perforation 11 and the first inner perforation 12 are evenly distributed on the top, the first outer perforation 11 is in the shape of a cross, the first inner perforation 12 is a square, and the middle part of the bottom template 1 is provided with a first lifting ring 13. The upper part of the bottom template 1 is also provided with a first connecting column 14; the upper part of the middle template 2 is a concave structure, and the second outer perforation 21 and the second inner perforation 22 are evenly distributed on the middle template 2. The second outer perforation 21 is in the shape of a cross, the second inner perforation 22 is a square, the middle ...

Embodiment 2

[0060] like Figure 1 to Figure 8 As shown, an external formwork and auxiliary device for inclined pile construction, the external formwork includes a bottom formwork 1, a middle formwork 2 and a top formwork 3 that cooperate with each other, the bottom formwork 1 is rectangular, and the bottom formwork 1 The first outer perforation 11 and the first inner perforation 12 are evenly distributed on the top, the first outer perforation 11 is in the shape of a cross, the first inner perforation 12 is a square, and the middle part of the bottom template 1 is provided with a first lifting ring 13. The upper part of the bottom template 1 is also provided with a first connecting column 14; the upper part of the middle template 2 is a concave structure, and the second outer perforation 21 and the second inner perforation 22 are evenly distributed on the middle template 2. The second outer perforation 21 is in the shape of a cross, the second inner perforation 22 is a square, the middle ...

Embodiment 3

[0063] like Figure 1 to Figure 8 Shown: A construction method for external formwork and auxiliary devices used for inclined pile construction, including the pre-order work of opening holes, laying steel mesh, erecting steel arches, spraying concrete and lowering the reinforcement cages, and also includes the following steps:

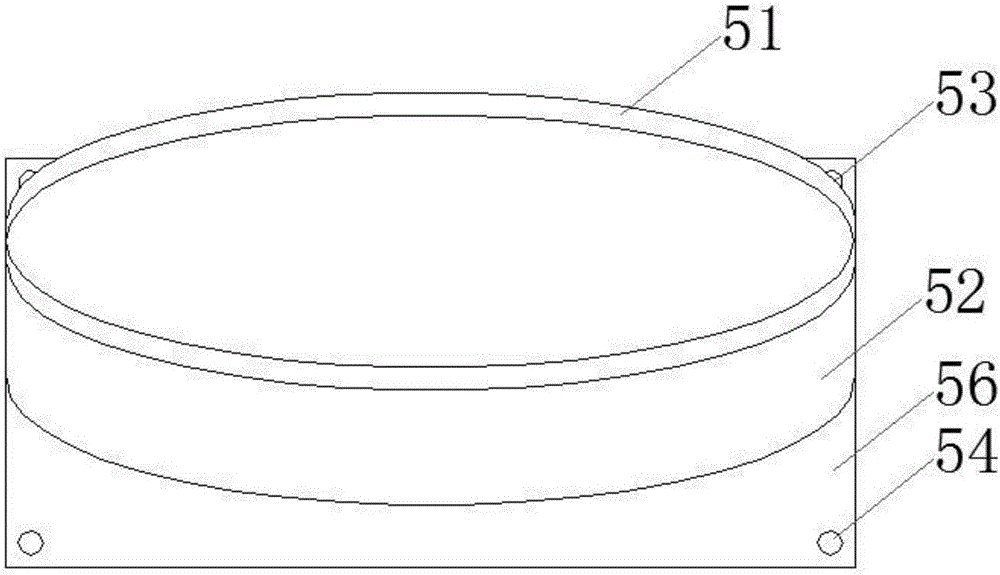

[0064] Step 1: Install the diversion tank 5 on the fixed formwork 3

[0065] Step 2: Set up the bottom template 1

[0066] A1, the bottom formwork 1 is passed through the vertical steel bar 8 reserved at the bottom of the inclined pile mouth at the mouth of the inclined pile and the steel mesh steel bar 7 reserved by the steel mesh;

[0067] A2. Bind and fix the bottom formwork 1 to the bottom of the pile opening of the inclined pile;

[0068] A3. Concrete is poured to the highest point not exceeding the bottom formwork 1, and at the same time, a vibrator is used to vibrate and degas the poured concrete;

[0069] Step 3: Set up the middle template 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com