Oscillating type oil pressure wet spraying machine

A swing type, wet blasting machine technology, applied in wellbore lining, tunnel lining, underground chambers, etc., can solve the problems of easy generation of open fire, low work efficiency, hidden dangers, etc., to improve safety, reduce weight, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

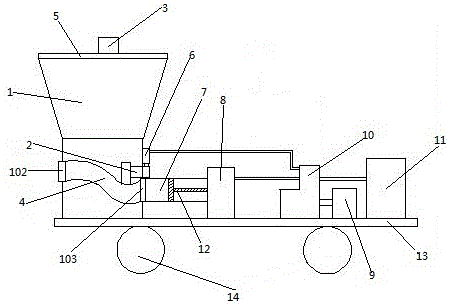

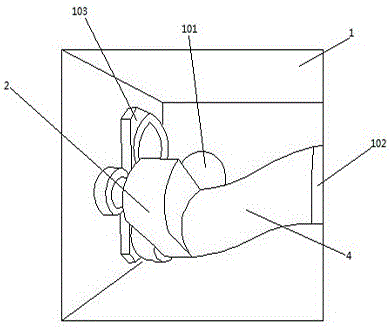

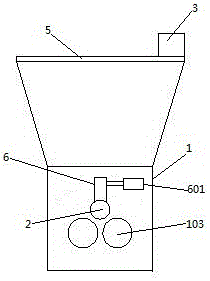

[0018] As shown in the figure, a swing type oil pressure wet spraying machine includes an underframe 13 and a power system 14 that controls the movement of the underframe 13. On the underframe 13, a material bin 1, a material cylinder 7, and a piston pump 8 are arranged. The side wall of the bottom of the silo 1 is provided with a discharge port 102, and the side wall opposite to the discharge port 102 is provided with two horizontally arranged material cylinder mouths 103, between the material discharge port 102 and the material cylinder mouth 103 is connected with feeding pipe 4, and one end of feeding pipe 4 is connected with the discharge port 102 in rotation, and the other end is docked with two material cylinder mouths 103 in turn during the rotation of feeding pipe 4. The preferred scheme is: The two ends of the feeding pipe 4 are not in the same horizontal position, and the high end is connected to the discharge port 102 in rotation, and the low end is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com