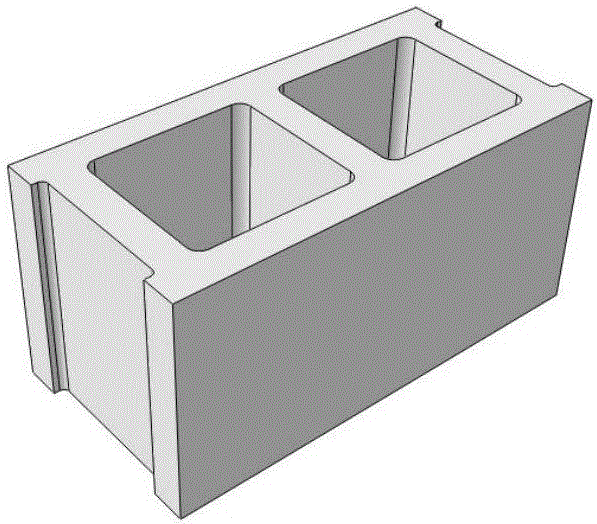

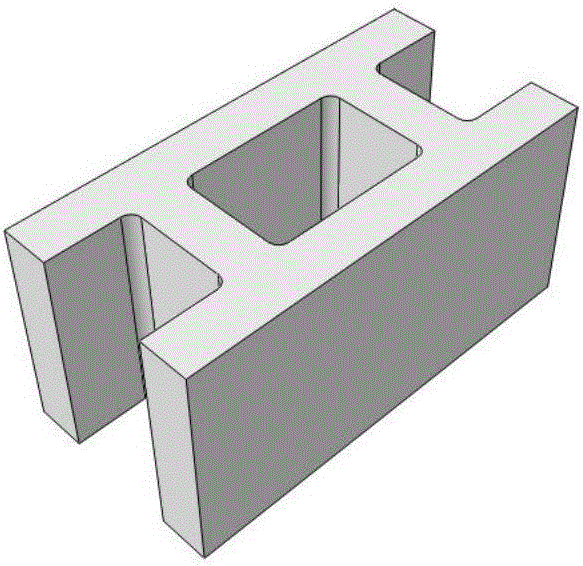

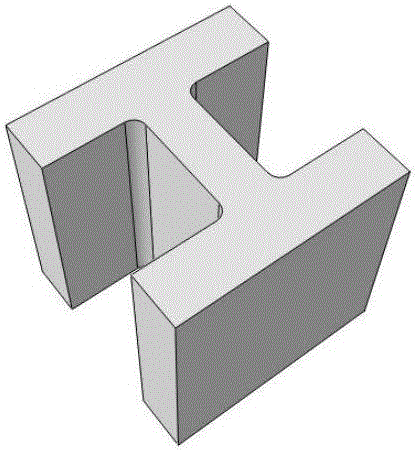

Green and environmentally-friendly concrete hollow block and production method thereof

A hollow block, green and environmentally friendly technology, applied in the direction of building components, sustainable waste treatment, solid waste management, etc., can solve the problems of polluting the environment, waste concrete occupying land, etc., to solve the pollution of the environment, solve the occupation of land, and expand the application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a green and environmentally friendly concrete hollow block, which is specifically implemented according to the following steps:

[0031] S1. Weighing: 14 parts of water, 31-35 parts of cement, 65-70 parts of fine aggregate, 120-128 parts of coarse aggregate, wherein the coarse aggregate is recycled coarse aggregate or recycled coarse aggregate and natural For a mixture of coarse aggregates, the ratio of recycled coarse aggregate to the weight of the entire coarse aggregate (substitution rate of recycled coarse aggregate) is 0 to 100%, wherein the replacement rate of recycled coarse aggregate is preferably 0%, 30%, 50%, 70%, 100%;

[0032] S2, mixing and stirring, put the weighed components into the mixer and stir evenly, then add water and water reducer and stir evenly to obtain the mixture;

[0033] S3, pressing and forming, pouring the obtained mixture into a mold, performing vibration pressing and forming, demoulding aft...

Embodiment 1

[0036] MU7.5 green environmental protection concrete hollow block, the specific components (taking the replacement rate of recycled coarse aggregate as 50% as an example) are as follows: 14 parts of water, 31 parts of cement, 65 parts of fine aggregate, 64 parts of natural coarse aggregate , 64 parts of recycled coarse aggregate. After the preparation steps: mixing and stirring→press molding→curing for 28 days, the green and environmentally friendly concrete hollow blocks are made and sent for sample testing. T 8239-2014 and "Code for Building Structure Loads" GB50009-2012. The test results are shown in Table 1 below. It is worth explaining: through the test results, it is found that the strength grade of green concrete hollow blocks prepared with other recycled coarse aggregate replacement rates (0%, 30%, 70%, 100%) can reach MU7.5.

[0037] Table 1 Performance test results of green concrete hollow blocks (MU7.5)

[0038]

Embodiment 2

[0040]The material selected in this embodiment is the same as that in Example 1, MU10 green environmental protection concrete hollow block, and the specific components (taking the replacement rate of recycled coarse aggregate as 70% as an example) are as follows: 14 parts of water, 35 parts of cement, 70 parts Fine aggregate, 36 parts of natural coarse aggregate, 84 parts of recycled coarse aggregate. After the preparation steps: mixing and stirring→press molding→curing for 28 days, the green concrete hollow block is made and sent for sample testing. The testing basis for strength grade MU10, bulk density and water absorption is "Ordinary Concrete Small Hollow Block" GB / T 8239 -2014 and "Code for Building Structure Loads" GB50009-2012. The test results are shown in Table 2 below. It is worth explaining: through the test results, it is found that the strength grade of the green concrete hollow blocks prepared with other recycled coarse aggregate replacement rates (0%, 30%, 50%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com