A tunnel central drainage pipe and its laying method

A tunnel center and laying method technology, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve the problem of inability to maintain the straightness or gradient of the central drainage pipe, the reduction of the water permeability of the central drainage pipe, and the blockage of the central drainage pipe drain hole, etc. problems, to achieve the effect of ensuring stability and drainage, preventing clogging and avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

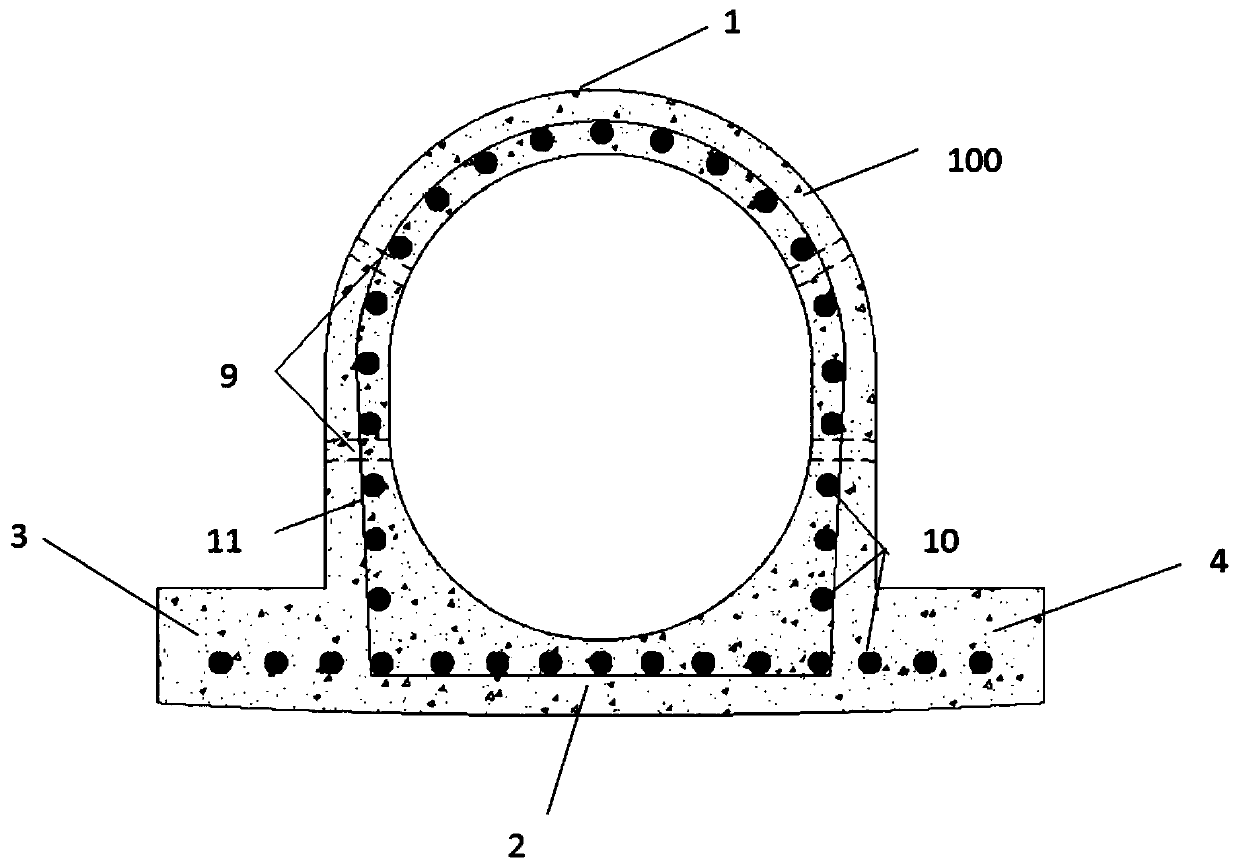

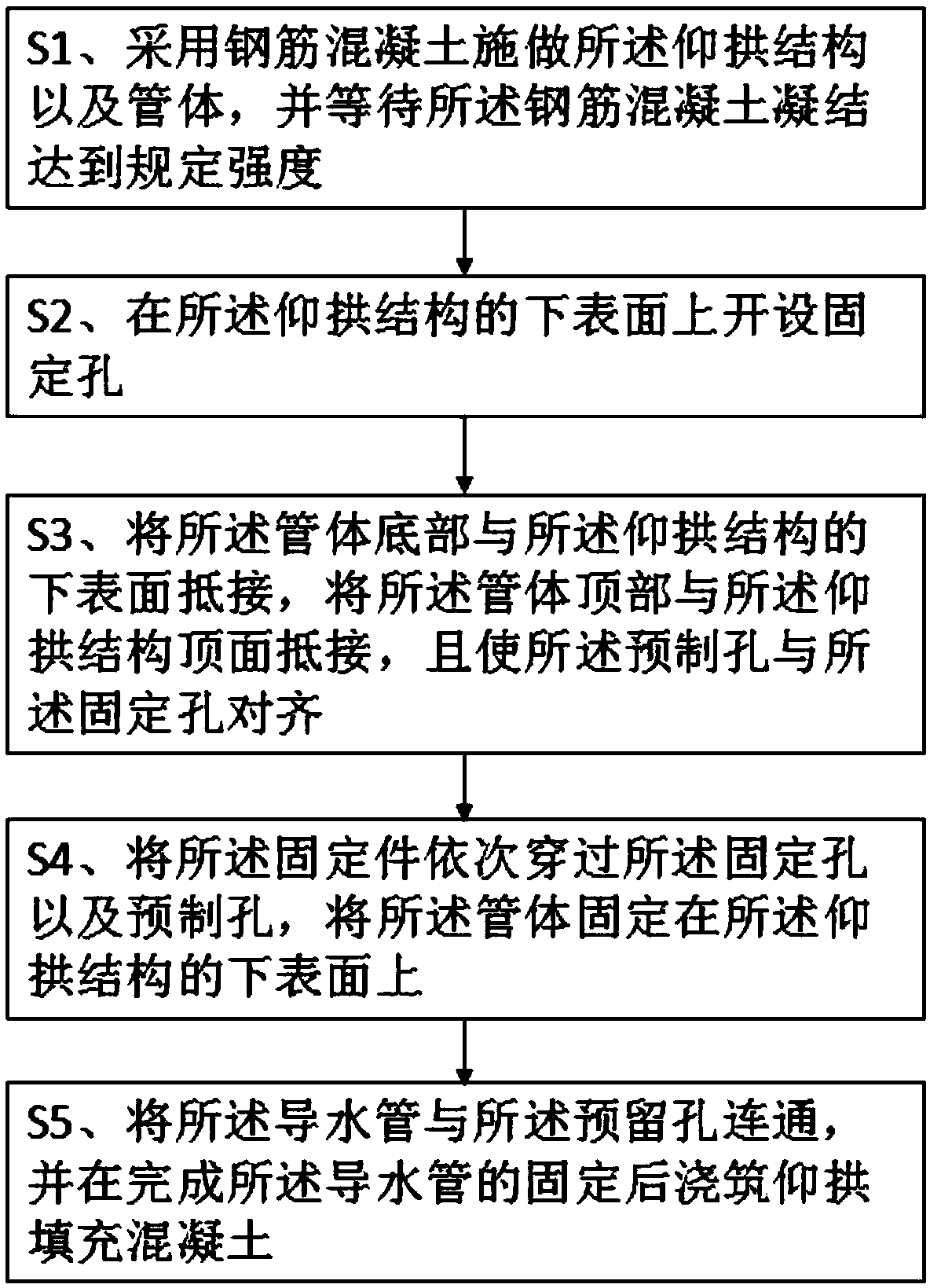

[0046] Such as figure 1 As shown, the tunnel central drainage pipe of the present invention includes a reinforced concrete pipe body 100, the cross section of which is arched, and the bottom of the pipe body 100 is flat, and the top 1 of the pipe body is arc-shaped. At the same time, the bottom 2 of the tube body has a first wing plate 3 and a second wing plate 4 extending to both sides of the tube body 100 along a direction perpendicular to the length of the tube body. Thus, the overall cross-section formed by the tube body 100 and the first wing plate 3 and the second wing plate 4 is roughly “Ω”, so it is not easy to shake and rotate, the setting of the tube seat can be omitted, and the process is simplified. .

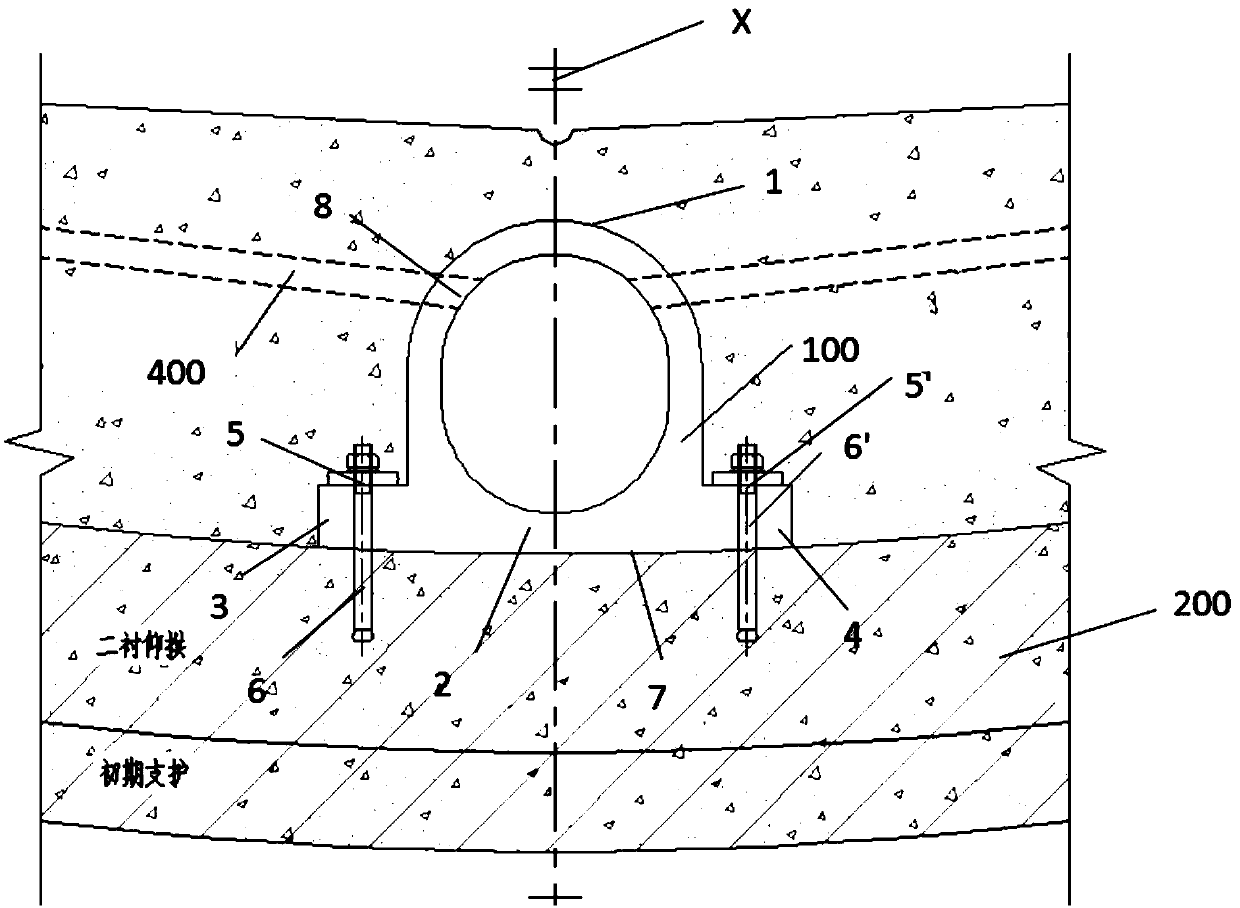

[0047] In this example, if figure 2 As shown, the pipe body 100 is arranged on the upper part of the inverted arch structure 200; the curvature of the top 1 is the same as that of the top surface of the inverted arch structure, and the arc-shaped pipe body top 1 ...

Embodiment 2

[0058] Such as Figure 4 As shown, the tunnel central drainage pipe of the present invention only includes a reinforced concrete pipe body 100', the cross section of the pipe body 100' is arched, and the bottom 2' of the pipe body is a plane. Similarly, the cross-section of the tube body 100' is non-traditionally circular, so it is not easy to shake and rotate, and the setting of the tube seat can be omitted, which simplifies the process.

[0059] Such as Figure 5 As shown, the pipe body 100' is disposed in the groove 500 below the center of the bottom of the inverted arch structure 200.

[0060] Concrete is sprayed on both side walls and the inner surface of the bottom of the groove 500 to form a first side wall concrete layer 12, a second side wall concrete layer 13 and a bottom concrete layer 14; the pipe body 100' is arranged on the On the bottom concrete layer 14 of the trench 500.

[0061] Preferably, in order to place the pipe body 100' stably, a C20 concrete leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com