A truss support structure member pipe and its overlapping method

A support body and structural rod technology, applied in the direction of pipeline support, flange connection, passing components, etc., can solve problems such as single function, complex construction, and complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

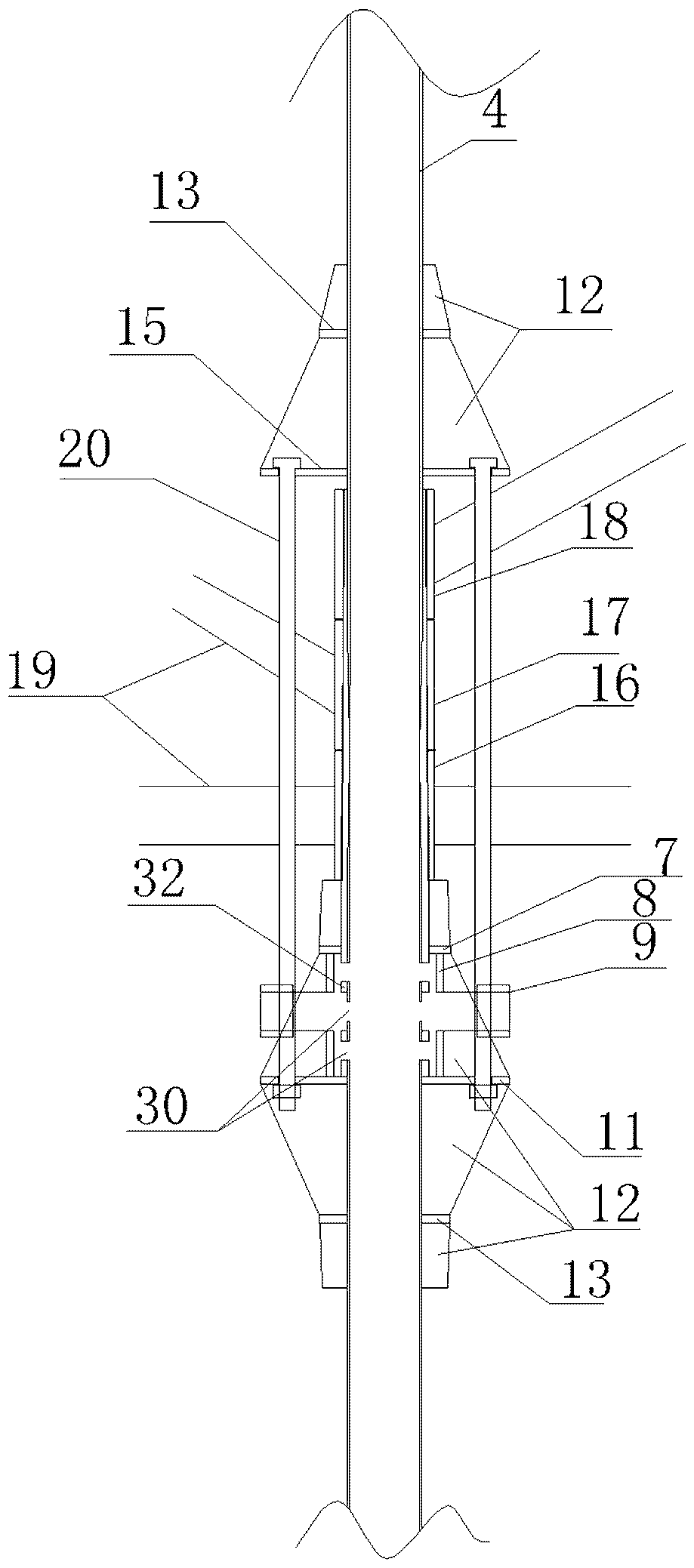

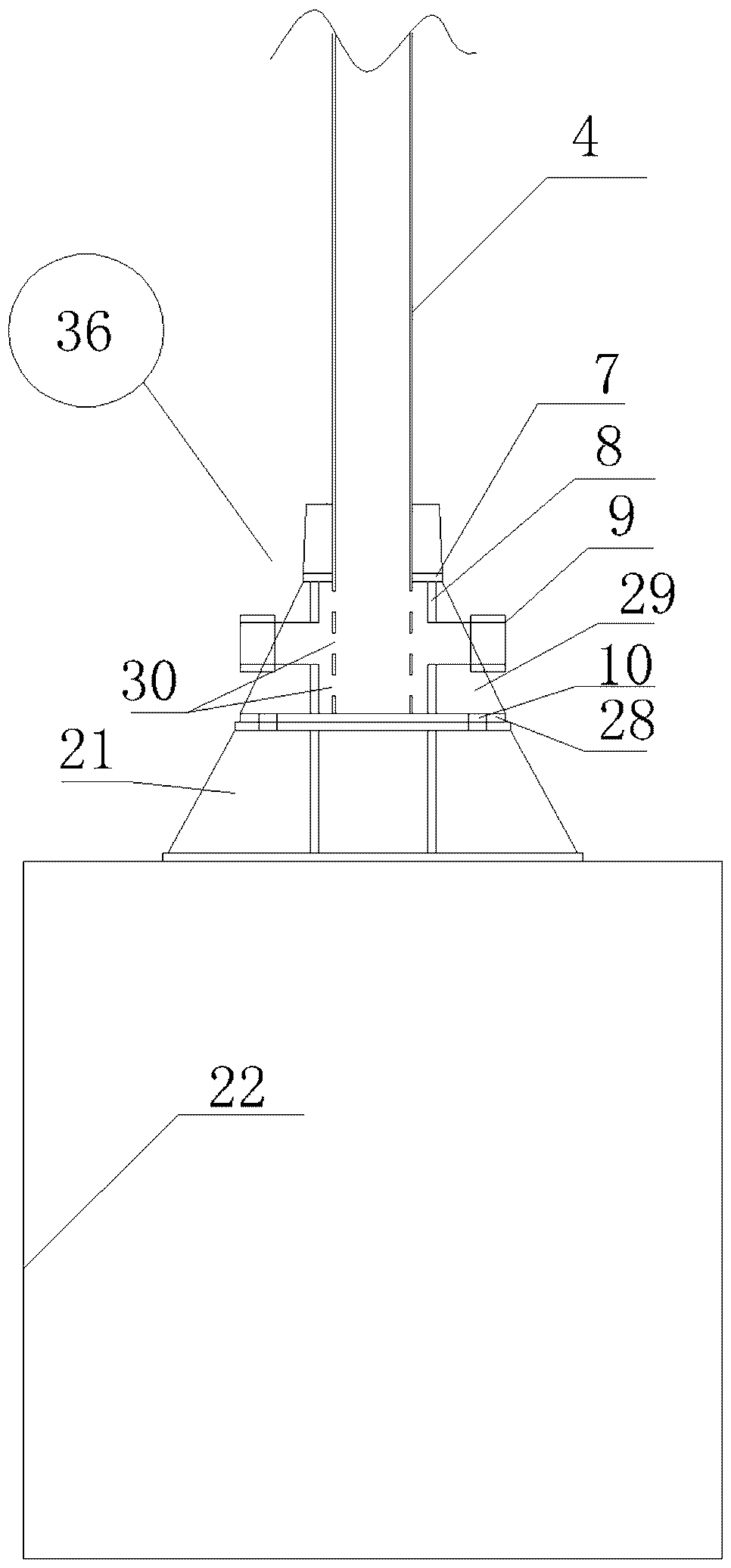

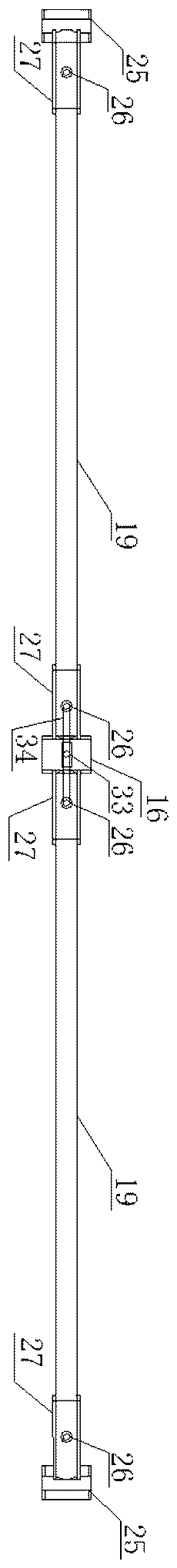

[0027] Such as figure 1 --- Figure 21 Shown: a truss support structure member pipe, characterized in that it includes a connecting member pipe and a connecting member pipe which have both the load-bearing function of the truss support structure member transferring stress and the ordinary pipeline gas and liquid transportation function The connecting rod pipe includes: connecting pipe shaft (4), connecting pipe base (35 or 36), connecting pipe upper joint (1 or 3), connecting pipe lower joint (2), connecting pipe top head (31); the connecting pipe shaft (4) is a strip-shaped pipe with a circular cross-section, its upper end is airtightly fixedly connected with the upper joint (1 or 3) of the communicating pipe, and its lower end is connected with the lower joint of the communicating pipe (2 ) or the integral connecting pipe base (36) is airtightly fixedly connected to form various forms of connecting pipe connecting rods, Figure 5 Shown are two representative connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com