Polyurethane modified epoxy resin adhesive material as well as preparation method and application thereof

An epoxy resin and polyurethane modification technology, applied in the field of adhesive materials, can solve the problems of poor toughness, easy dripping, bonding and filling and sealing at unfavorable gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

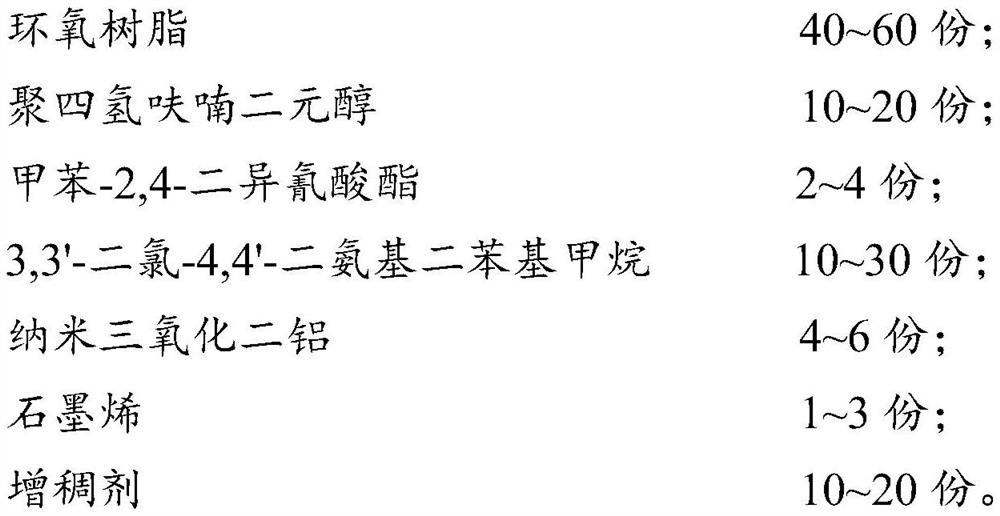

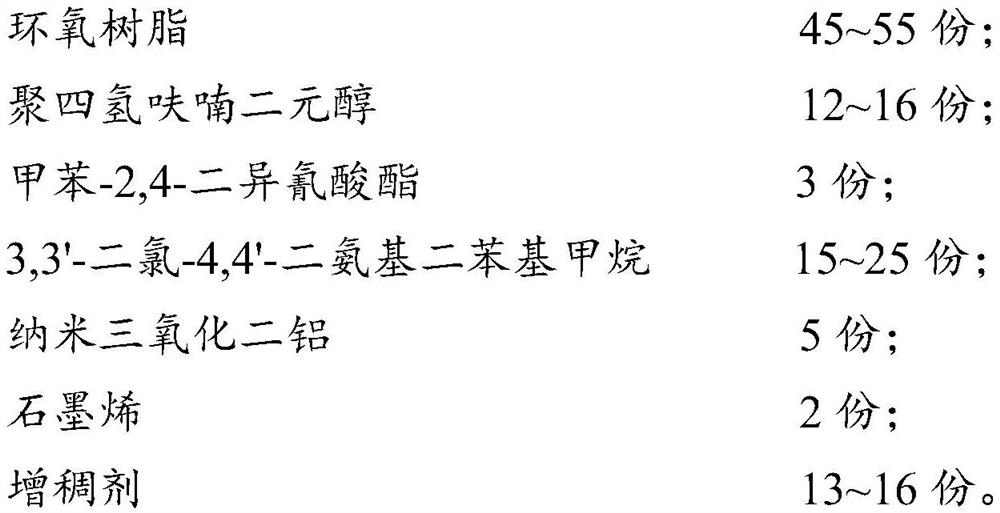

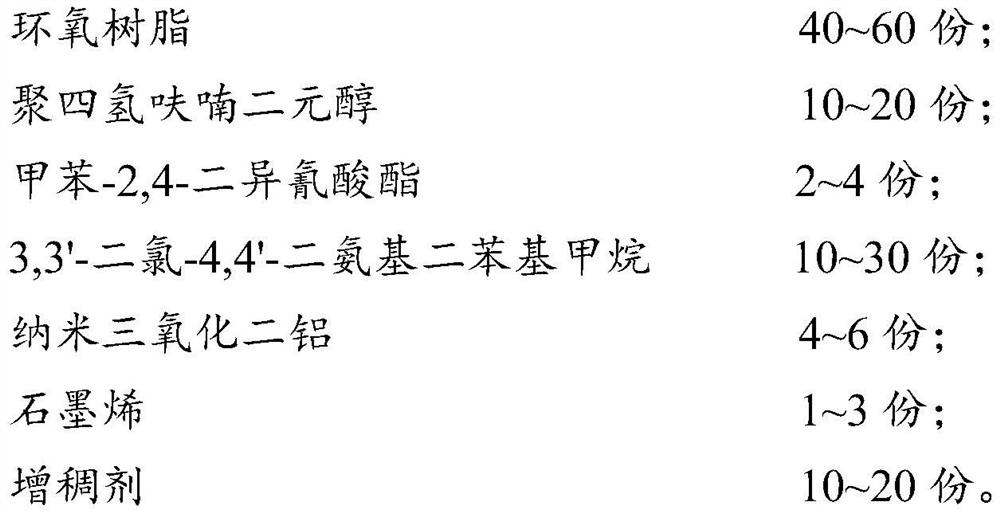

[0051] The present invention provides the preparation method of above-mentioned polyurethane modified epoxy resin adhesive material, comprises the following steps:

[0052] (1) mixing polytetrahydrofuran diol and toluene-2,4-diisocyanate for prepolymerization to obtain a polyurethane prepolymer;

[0053] (2) heating and mixing the polyurethane prepolymer, epoxy resin, nano-alumina, graphene, 3,3'-dichloro-4,4'-diaminodiphenylmethane and thickener, A polyurethane-modified epoxy resin adhesive material was obtained.

[0054] The invention mixes polytetrahydrofuran diol and toluene-2,4-diisocyanate for prepolymerization to obtain polyurethane prepolymer. In the present invention, the mixing is preferably stirring mixing, and the stirring speed is preferably 500-800 rpm, more preferably 600-700 rpm. In the present invention, the temperature of the pre-polymerization is preferably 55-65° C., more preferably 60° C., and the time is preferably 55-65 minutes, more preferably 60 minu...

Embodiment 1

[0074] The types and amounts of raw materials used in Example 1 are shown in Table 2.

[0075] The preparation method of polyurethane modified epoxy resin adhesive material is as follows:

[0076] (1) Put polytetrahydrofuran diol and toluene-2,4-diisocyanate into a flask, mechanically stir at a rate of 600 rpm in an oil bath at 60°C for 60 minutes, and react to obtain a polyurethane prepolymer;

[0077] (2) Add epoxy resin, nano-aluminum oxide, graphene, thickener, 3,3'-dichloro-4,4'-diaminodiphenylmethane into the polyurethane prepolymer, and heat up to 80 °C, mechanically stirred at a rate of 2000 rpm for 5 minutes, mixed evenly, and degassed in a vacuum oven;

[0078] (3) Put the obtained mixture in an oven at 120°C for 3 hours, and then add it to coat with a film coater, control the temperature of the film coater to 85°C, control the film thickness to 0.5±0.1mm, the width is about 10±1cm, and the length is 20 ±1cm, the temperature was lowered to room temperature, and the...

Embodiment 2

[0093] The types and amounts of raw materials in Example 2 are shown in Table 2. The preparation method is the same as in Example 1. The technical parameters of the cured polyurethane-modified epoxy resin adhesive material are shown in Table 4.

[0094] The technical parameters of the polyurethane-modified epoxy resin adhesive material after table 4 embodiment 2 curing

[0095]

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com