Low-constant-temperature closed magnesium electrolysis device

A technology of magnesium electrolysis and constant temperature, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of uneven width, single sealing measures, chlorine gas leakage, etc., to improve tightness, improve heat dissipation efficiency, ensure stability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

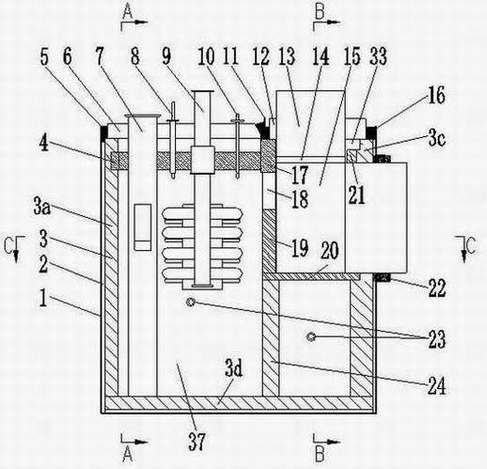

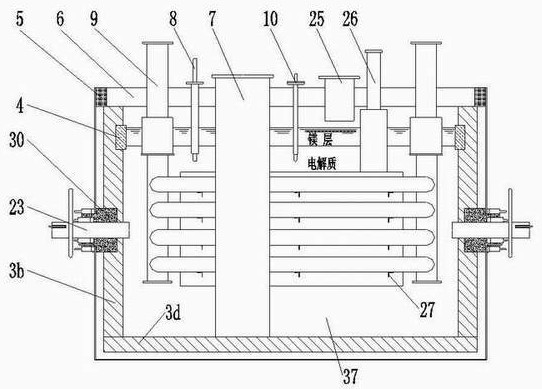

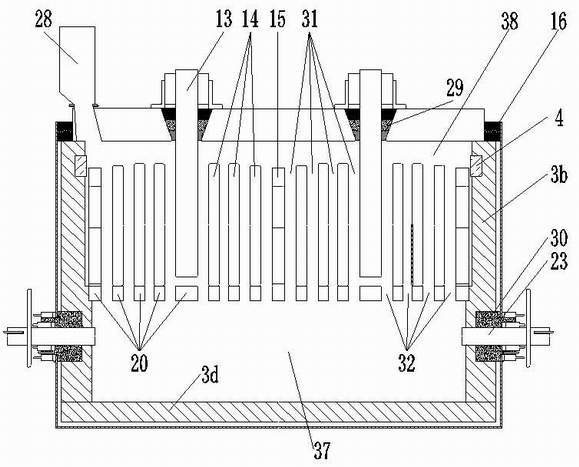

[0045] see figure 1 -5. Low constant temperature closed magnesium electrolysis device, including tank shell 1, magnesium electrolysis device refractory lining 3, partition wall 19, diversion block 20, anti-corrosion belt brick 4, back wall 21, feeding channel 7, melt cooler 9 and a heating electrode 23; the interior of the tank shell 1 is provided with a magnesium electrolysis device refractory lining 3; a flexible expansion plate 2 is provided between the magnesium electrolysis device refractory lining 3 and the tank shell 1, which can absorb the magnesium electrolysis device refractory lining The thermal expansion of the lining in the oven and during operation; the partition wall 19 and the guide block 20 divide the interior of the refractory lining 3 of the magnesium electrolysis device into a metal chamber 37 and a reaction chamber 38; the refractory lining 3 of the magnesium electrolysis device Including front wall 3a, side wall 3b, back wall 3c and tank bottom 3d; said f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com