Mounting alignment device for equipment and steel structure

A steel structure and equipment technology, applied in the direction of mechanical equipment, supporting machines, etc., can solve the problems of inconvenient operation, inaccurate alignment, long time for installation and alignment, etc., and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

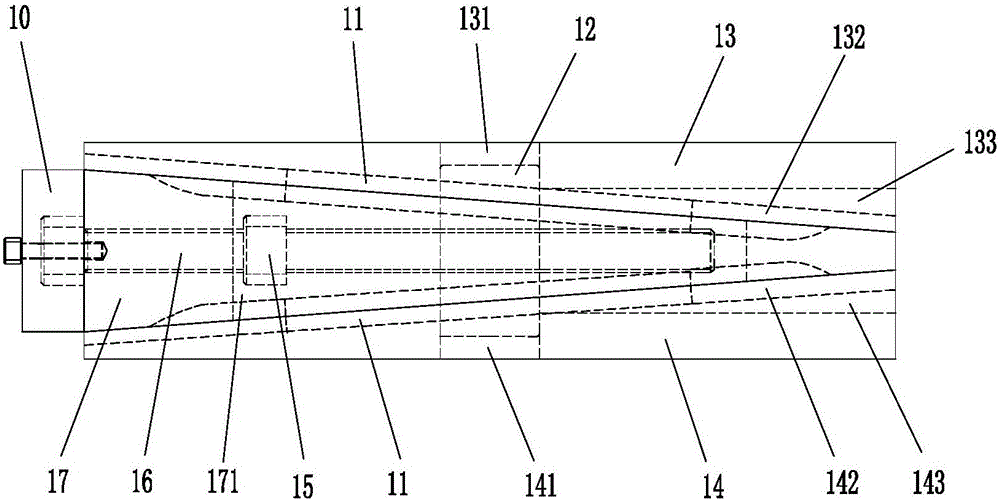

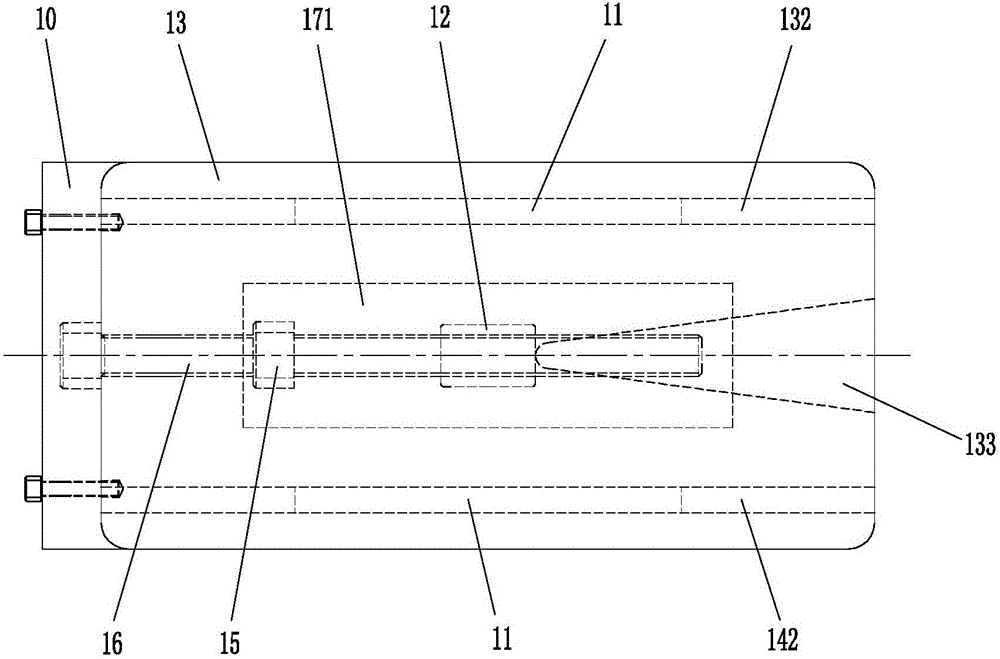

[0021] In the following, the equipment and steel structure installation and alignment device of the present invention will be further described in detail with reference to the drawings and specific embodiments:

[0022] For the convenience of description, the "front" mentioned below is figure 1 with figure 2 The right end of the “rear” is figure 1 with figure 2 The left end.

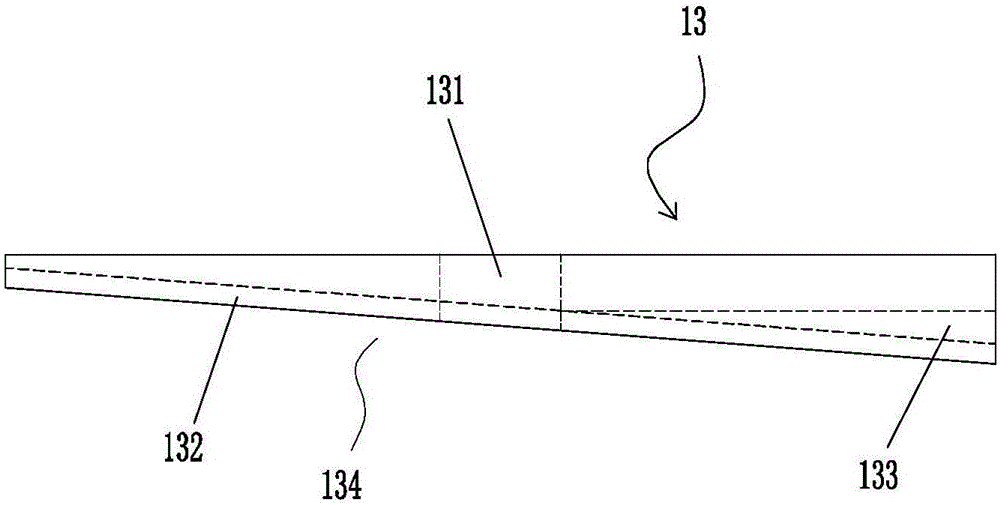

[0023] Such as figure 1 with figure 2 As shown, in this specific embodiment, the equipment and steel structure installation and alignment device of the present invention includes an upper shim 13, a middle shim 17, an adjusting bolt 16, a push-pull block 12, and a lower shim 14. The middle shim 17 is located on the upper Between the horn 13 and the lower horn 14, the top and bottom surfaces of the middle horn 17 are inclined to the front (see figure 1 with Figure 5 ), the longitudinal section of the middle shim 17 is an isosceles trapezoid, which is exactly the shape, the front of the middle shim 17 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com