Flame tube for triple-scroll combustion in advanced low-pollution turbine engines

A turbine engine and flame tube technology, which is applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of low compactness, reduced engine thrust-to-weight ratio, and large length and diameter of the flame tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

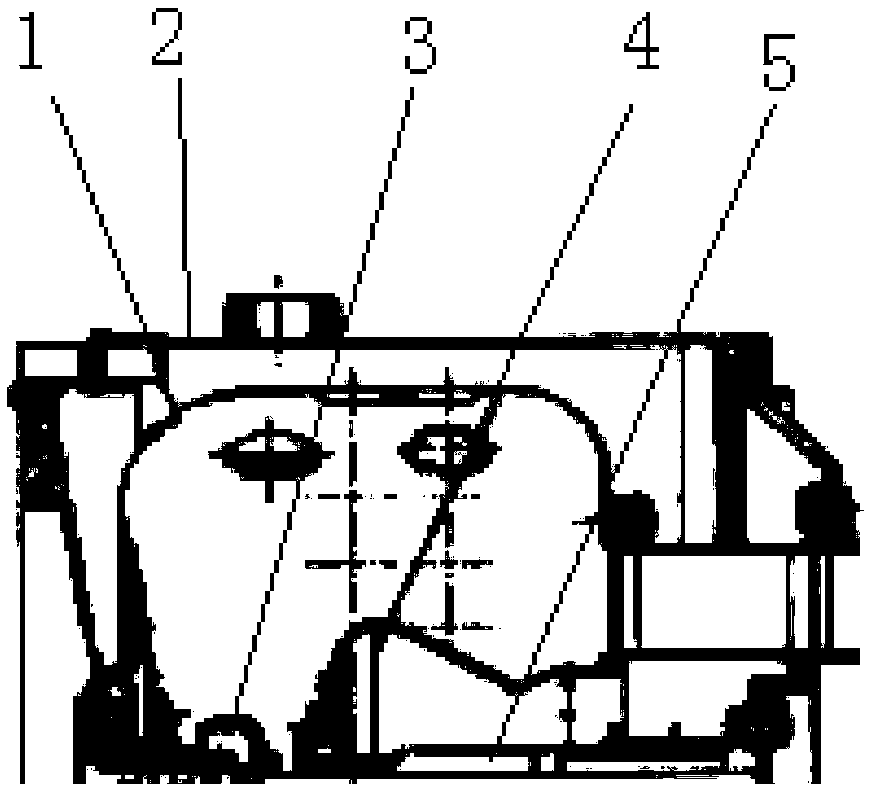

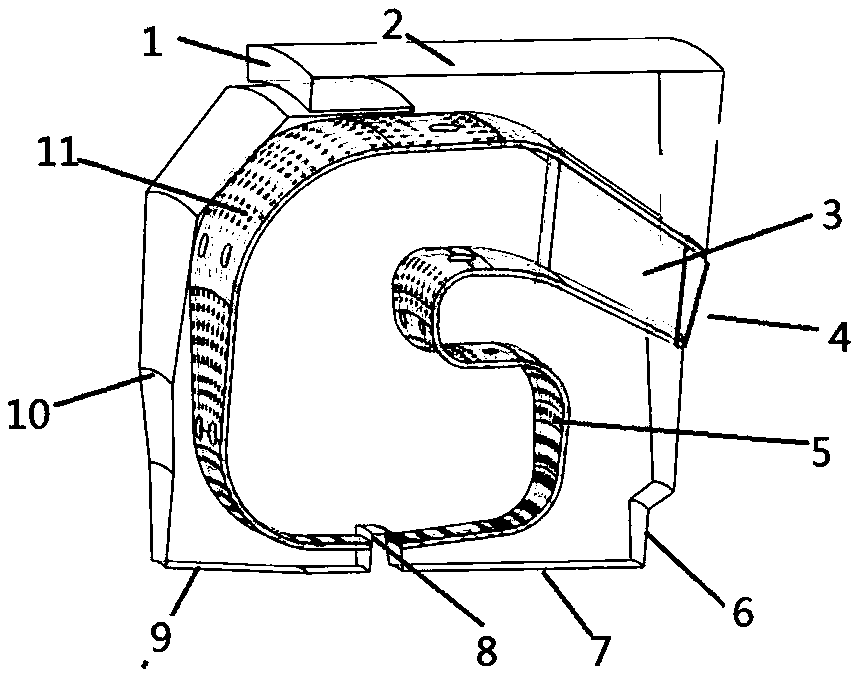

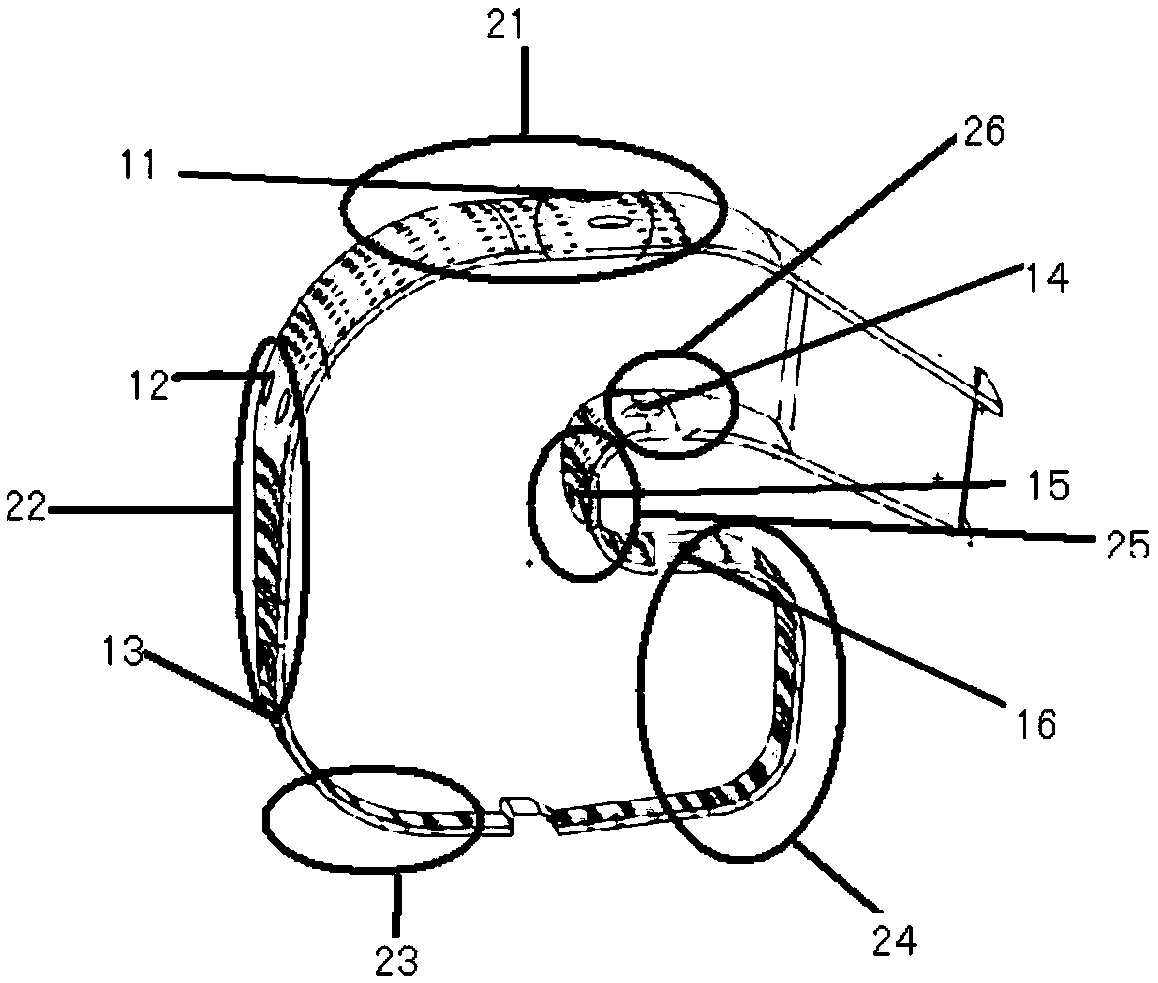

[0041] Domestic and foreign studies on low-pollution and low-emission turbine engine combustors have generally proved that the combustion structure with the characteristics of RQL (Rich / Quick Quenching / Lean (RQL) combustion technology) can effectively reduce the emission of combustion pollutants. Therefore, according to the combustion mechanism, this scheme designs a flame cylinder scheme with a C-shaped structure.

[0042]Thereby, the present invention provides a kind of flame cylinder that is applicable to the combustion of the three-scroll system organization of advanced low-pollution turbine engine, such as Figure 2-Figure 4 As shown, it includes: the combustion chamber inlet 1, the combustion chamber casing 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com