Testing method of water absorption property of high-nickel material

A technology of water absorption performance and test method, which is applied in material weighing, analyzing materials, measuring devices, etc., can solve the problems of large error in measurement results, temperature influence, poor comparability, etc., and achieve high repeatability and accurate test values. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Open the constant temperature and humidity box and set the temperature and humidity values. When the instrument runs to the set temperature and humidity, weigh a small amount of the material to be tested and place it in a balance with a measurement accuracy of 0.1 μg, automatically record the starting time and initial weight, and record the weight value according to the set interval.

[0023] Export the data and make a coordinate curve of weight and time.

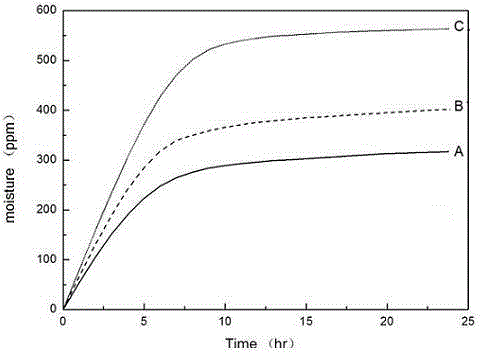

[0024] Such as figure 1 It shows that in the environment of 25°C RH 40%, among the water absorption performance curves of several domestic and foreign high-nickel materials A, B, and C, the water absorption performance of material A is the worst, and its process effect is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com