Battery thermal abuse test system and method based on automatic control and robot

A test system and robot technology, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of occupying the working time of testers, danger of testers, injury of testers, etc., so as to reduce the links of operation and monitoring, and save labor costs. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

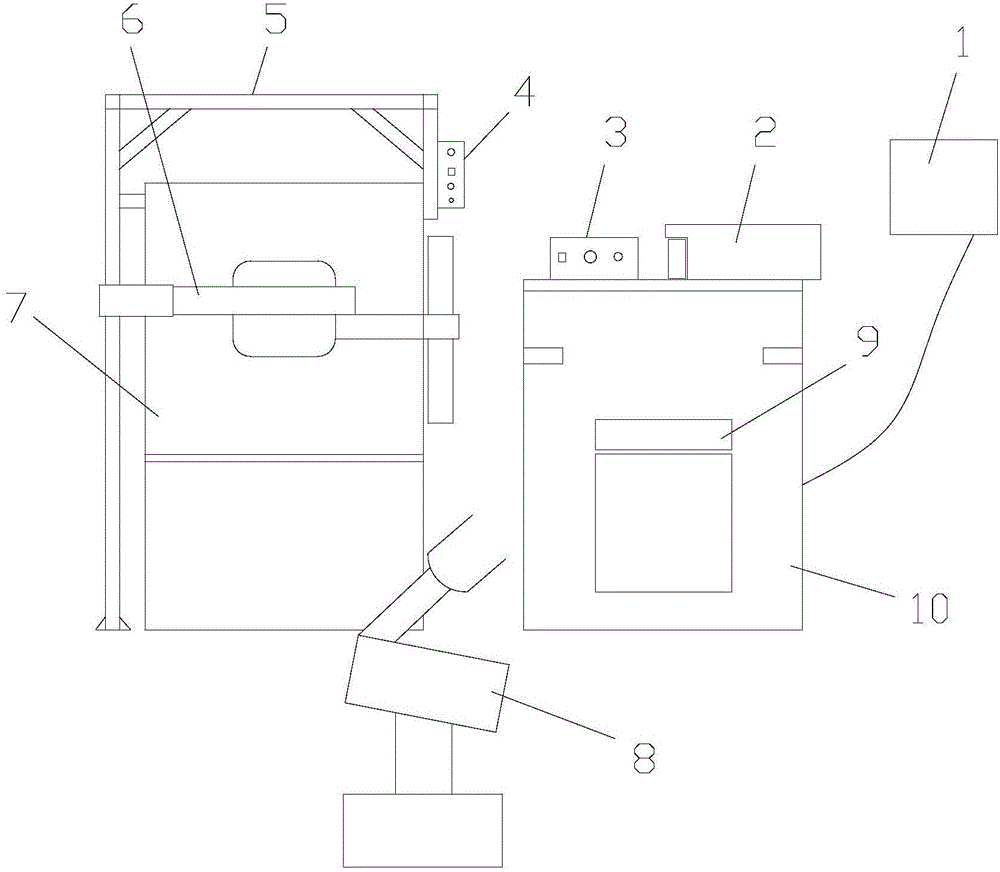

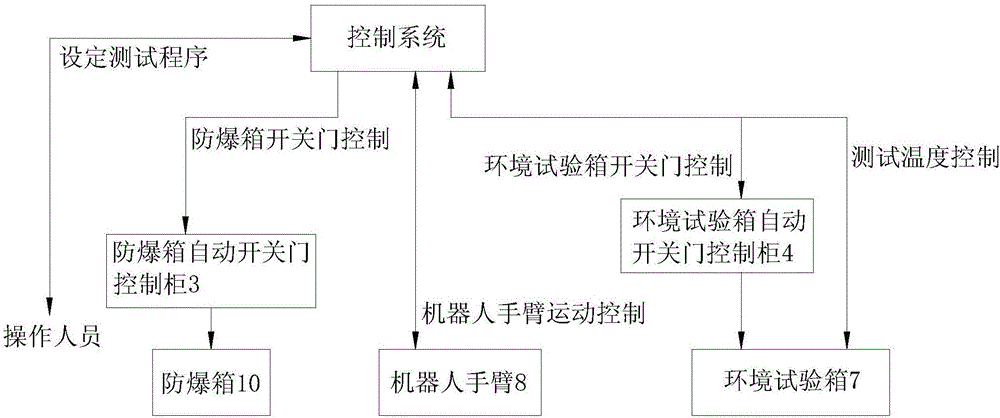

[0027] As shown in accompanying drawing, the present invention comprises: environment test box 7, explosion-proof box 10, control panel 1 and the robot arm 8 that is used to take and deposit test sample, is equipped with for controlling environment test box 7 switch doors on the environment test box 7 The automatic door switch device 6 of the environmental test box, the automatic door switch device 6 of the environmental test box is connected to the automatic door switch control cabinet 4 of the environmental test box by a line, the automatic door switch device 6 of the environmental test box is fixed by the bracket 5, and the explosion-proof box 10 is equipped with a The explosion-proof box automatic door opening and closing device 2 that controls the opening and closing of the explosion-proof box 10, the explosion-proof box automatic door opening and closing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com