Low-height biaxial deflection device having deflection axes intersected on surface of reflector and method

A deflection device and reflector technology, applied in installation, instrumentation, optics, etc., can solve the problems of large installation space, limited structural fundamental frequency, and reduced reliability, and achieve low vertical height, reduce optical path control errors, and respond fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

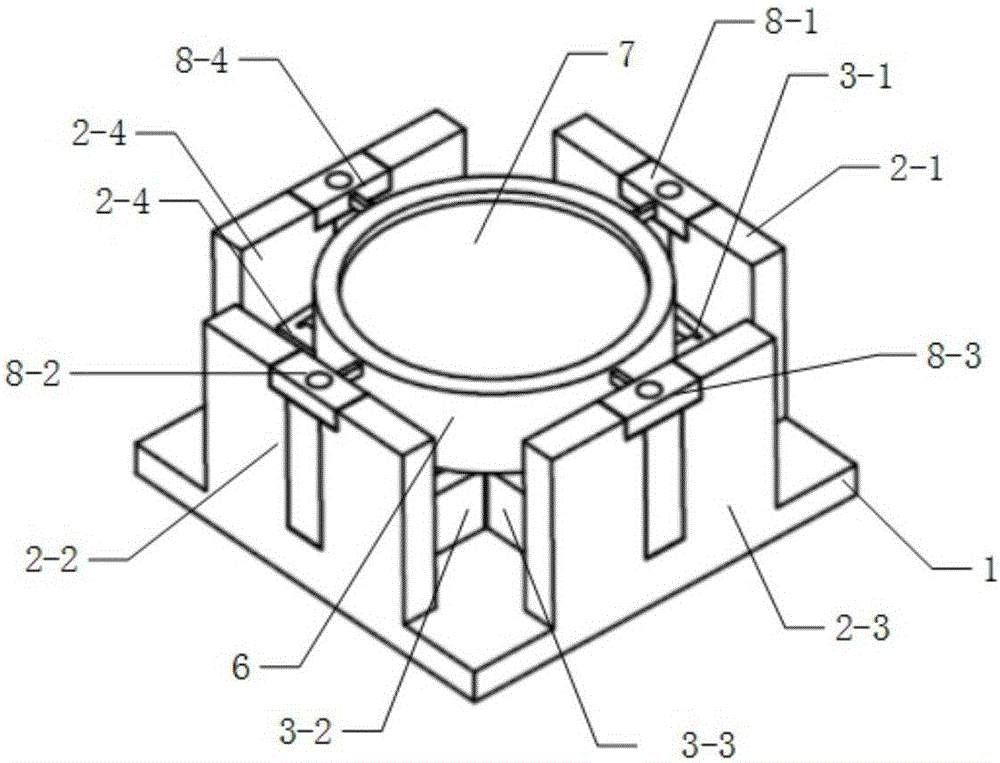

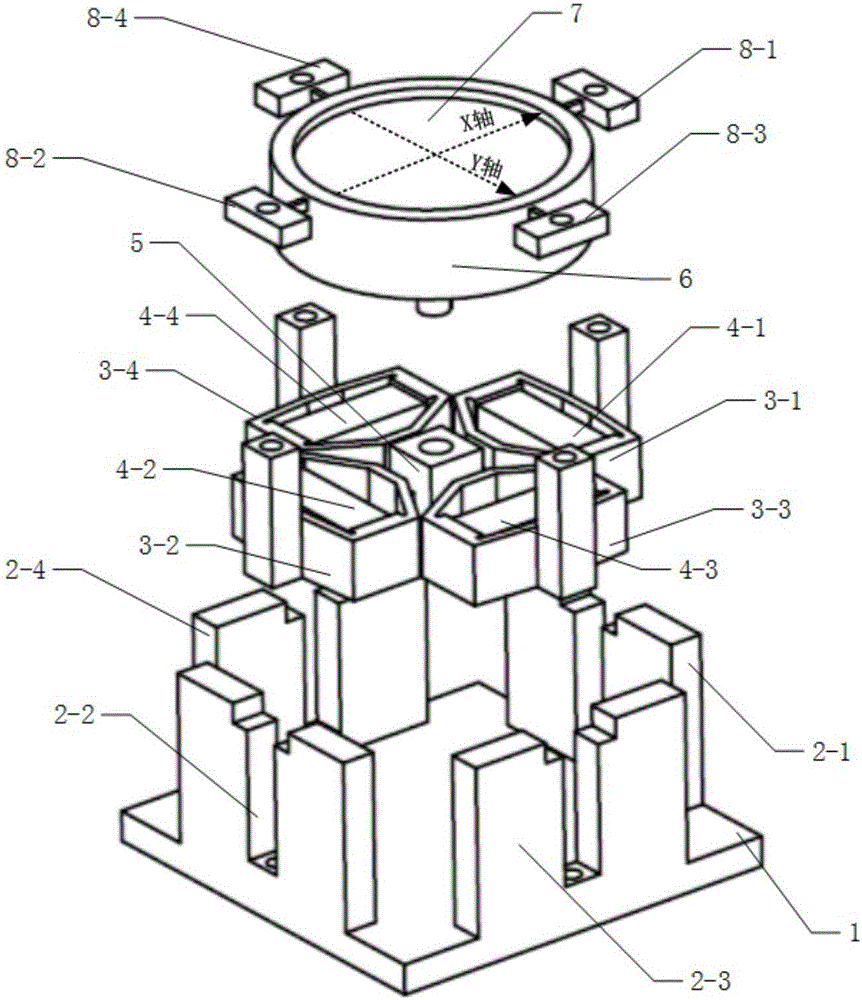

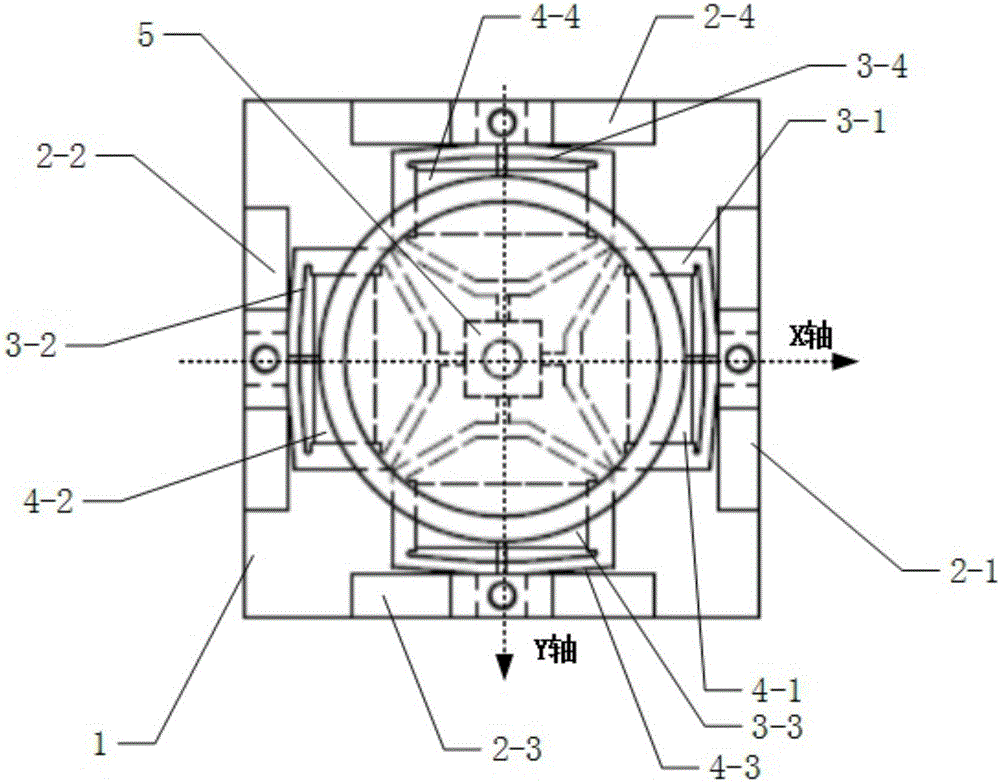

[0018] Such as figure 1 , figure 2 and image 3 As shown, a low-height biaxial deflection device of the present invention whose deflection axis intersects the mirror surface includes a base 1, a first fixed support 2-1, a second fixed support 2-2, and a base mounted on the base 1. The third fixed support 2-3 and the fourth fixed support 2-4, one end is fixed on the first elastic kite ring 3-1 on the first fixed support 2-1, and one end is fixed on the second fixed support 2 The second elastic kite-shaped ring 3-2 on the -2, the third elastic kite-shaped ring 3-3 fixed on the third fixed support 2-3 at one end, and the third elastic kite-shaped ring 3-3 fixed at the fourth fixed support 2-4 at one end The fourth elastic kite-shaped ring 3-4, the first piezoelectric ceramic 4-1 horizontally installed in the first elastic kite-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com