Design method for row space between pressure relief boreholes

A design method and support pressure technology, which is applied in calculation, special data processing applications, instruments, etc., can solve the problems of increasing drilling engineering volume, row spacing cannot achieve pressure relief effect, unfavorable coal and rock mass stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

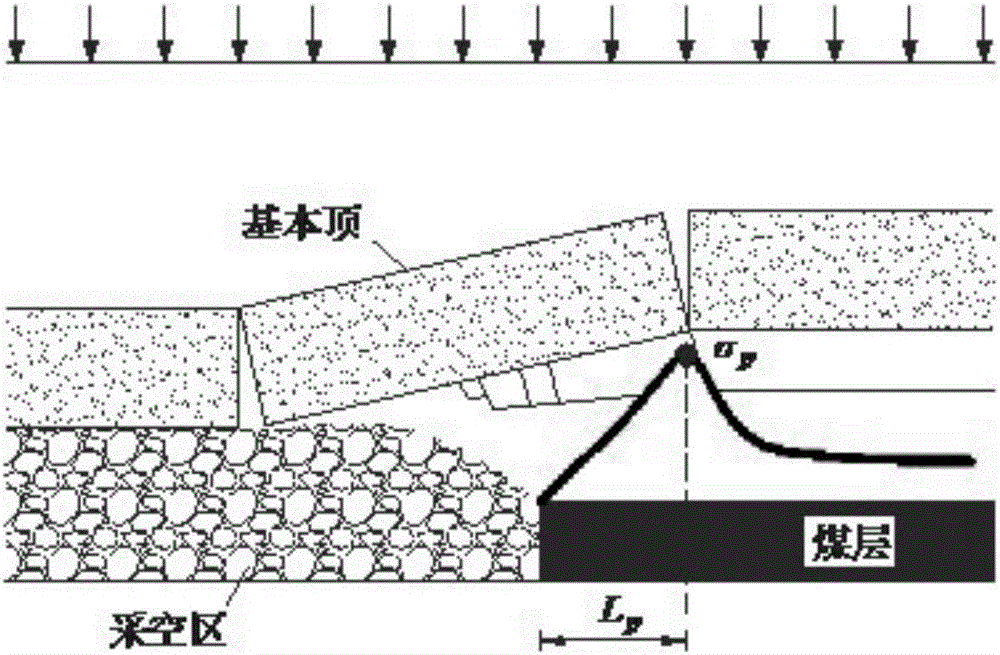

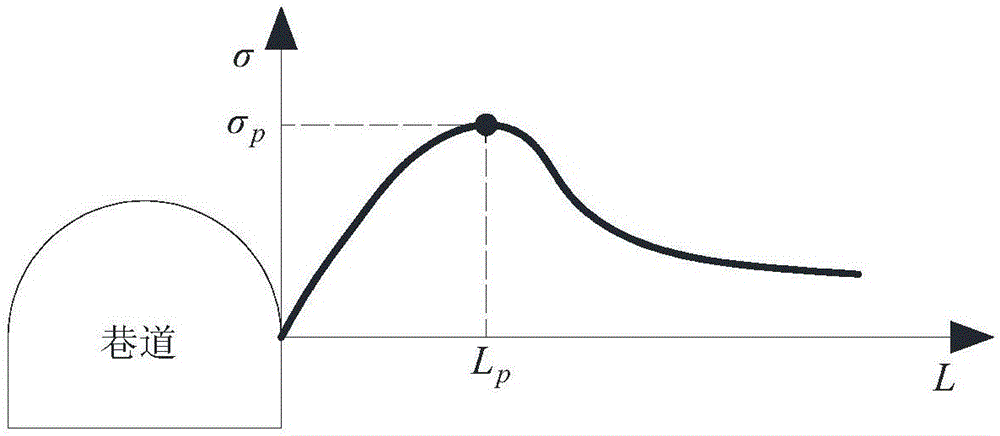

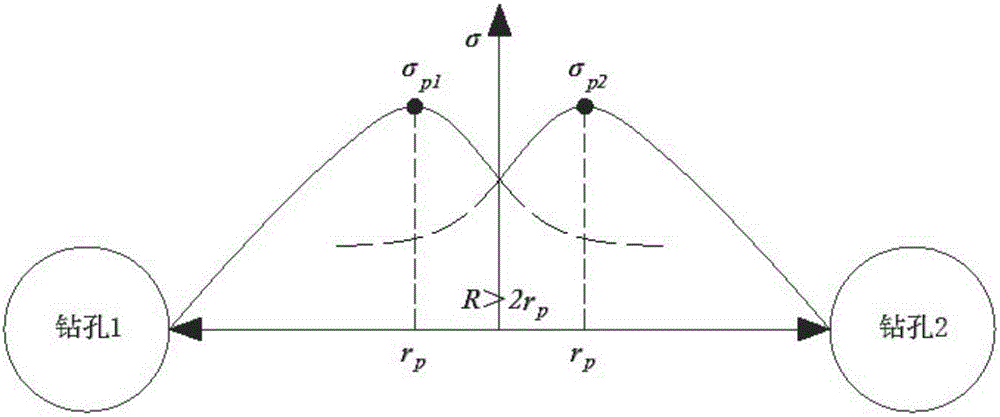

[0031] refer to Figure 1~6 The present invention is described, a method for designing the row spacing between pressure relief boreholes, the method is divided into three steps:

[0032] (S1) The application site of pressure relief drilling in coal mines is generally located in the working face, roadway and its adjacent positions. Before designing the row spacing between pressure relief drilling holes, it is first necessary to evaluate the stress environment at the pressure relief site and calculate the supporting pressure of the surrounding rock of the working face or roadway Peak σ p and its position L p . For the peak bearing pressure σ of the surrounding rock of the working face p and its position L p The calculation method is shown in formulas (1) and (2), according to the working face mining height m, side pressure coefficient A, coal internal friction angle Coal internal cohesion c, stress concentration coefficient k, average body force γ of overlying strata, buri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com