A Design and Analysis Method for Auxiliary Support System of Tunnel Steel Frame

An auxiliary support and design analysis technology, applied in calculation, instrumentation, geometric CAD, etc., can solve problems such as insufficient bearing capacity of arch foot foundation, adverse effects and lack of stability of steel frame arch foot, and achieve the effect of avoiding blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

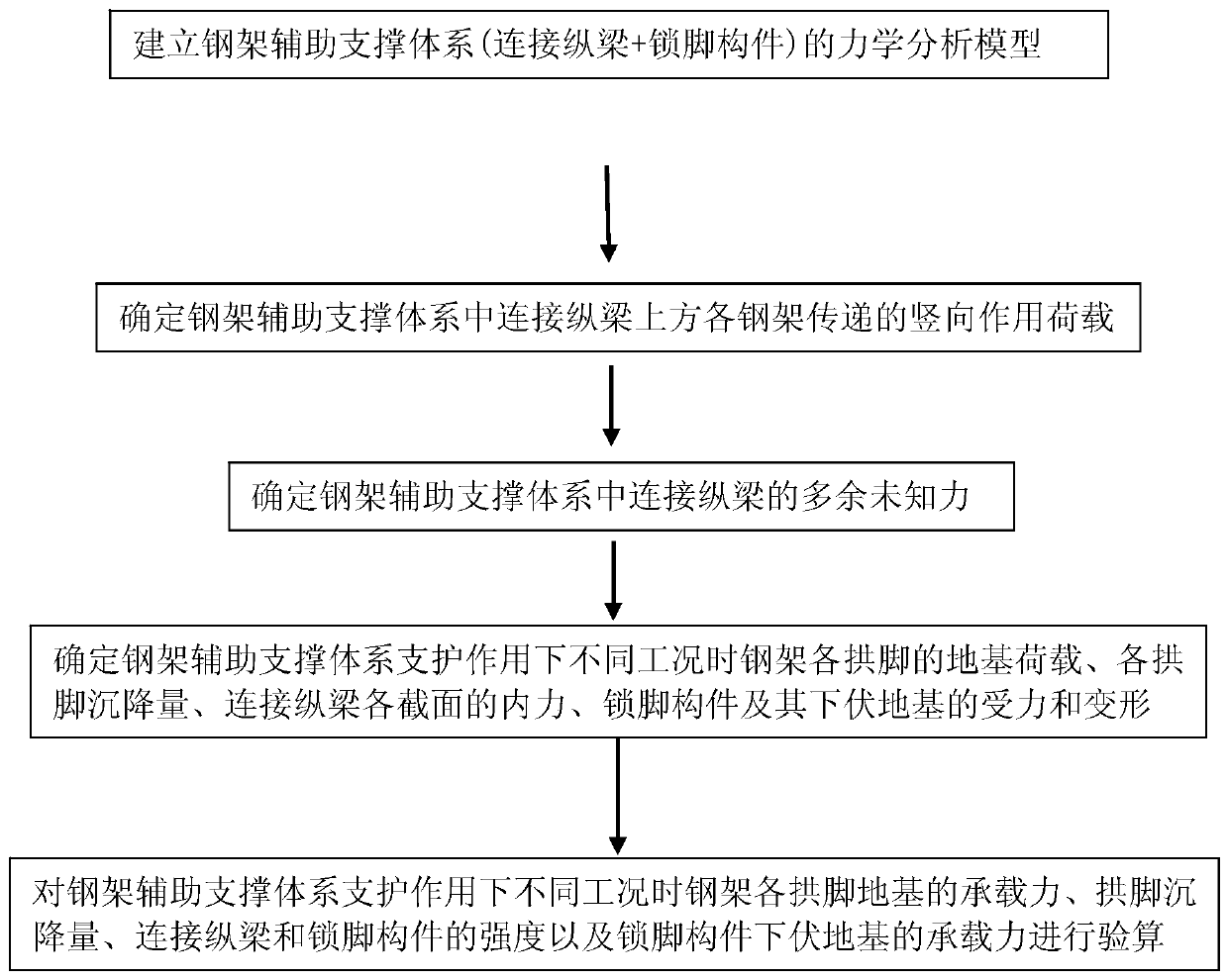

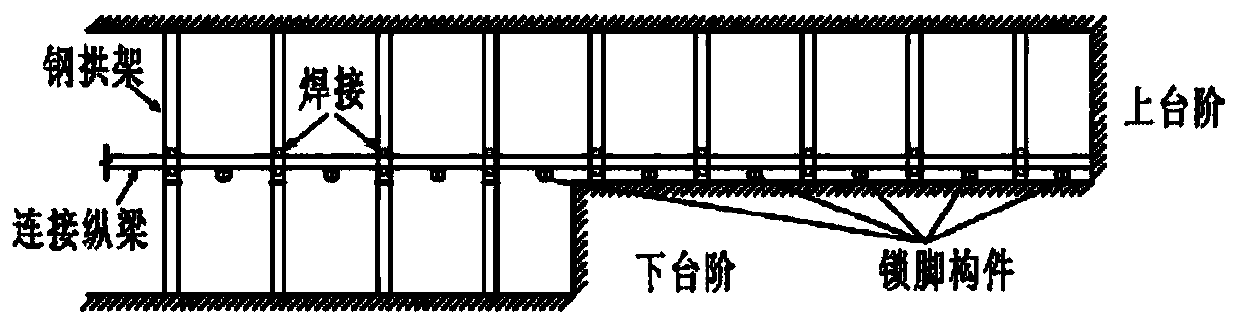

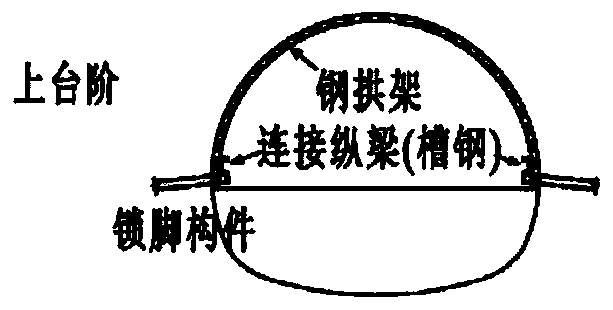

[0059] like figure 1 As shown, the design method is firstly based on the mechanism of action of the steel frame auxiliary support system (connecting longitudinal beam + locking foot member), such as Figure 2a As shown in and b, the mechanical analysis model of the steel frame auxiliary support system (connecting longitudinal beam + locking foot member) is established, such as Figure 3a and b, and satisfy the following conditions:

[0060] (1) The connecting longitudinal beam at the bottom of the steel frame is regarded as a fixed end, and the connecting longitudinal beam not connected to the long section of the steel frame is regarded as a cantilever beam structure;

[0061] (2) The vertical acting load transmitted from top to bottom of the unconnected long section of the steel frame is jointly supported by the connecting longitudinal beam, the locking foot member and the arch foot foundation. For the connecting longitudinal beam, it is subject to the vertical load transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com