A pressure control method and device

A technology of pressure value and chamber pressure, applied in transportation and packaging, electrical components, conveyor objects, etc., can solve the problem of long waiting time for pressure recovery of TC chamber, and achieve the effect of shortening pressure recovery time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

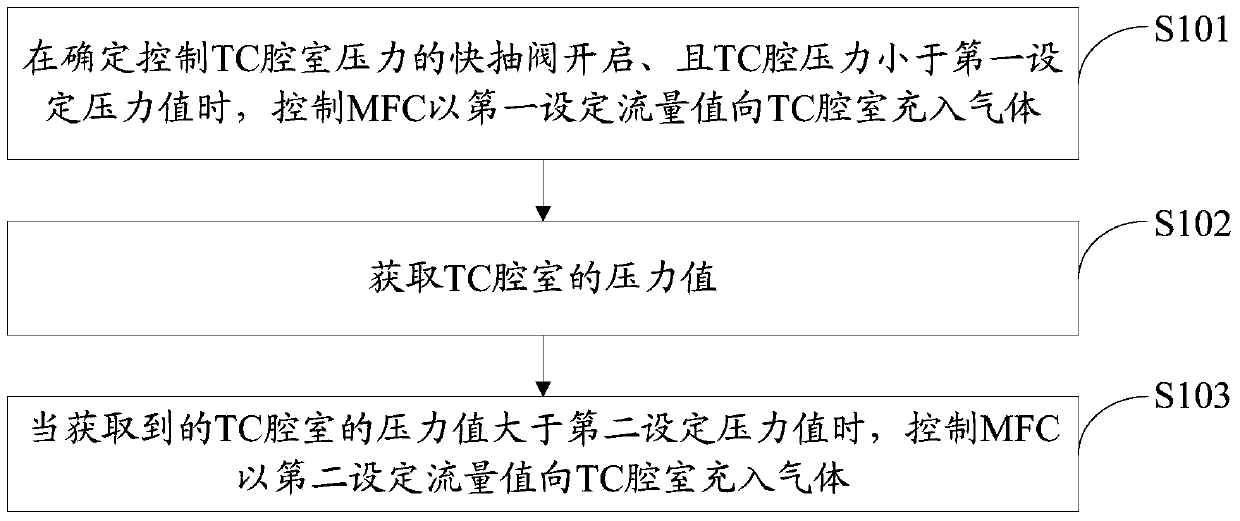

[0028] refer to figure 2 , shows a flow chart of the steps of a pressure control method in Embodiment 1 of the present invention.

[0029] The pressure control method of the present embodiment includes the following steps:

[0030] Step S101: When it is determined that the pumping valve controlling the pressure of the TC chamber is open and the pressure of the TC chamber is lower than the first set pressure value, control the MFC (Mass Flow Controller, mass flow controller) to the TC with the first set flow value The chamber is filled with gas.

[0031] Wherein, the pumping valve includes a slow pumping valve and a fast pumping valve, and the MFC is a device installed outside the TC chamber for charging gas into the TC chamber, and the device can also control the flow rate of the gas being charged. This application does not specifically limit how and where the MFC is installed outside the TC chamber. At the same time, those skilled in the art should understand that there i...

Embodiment 2

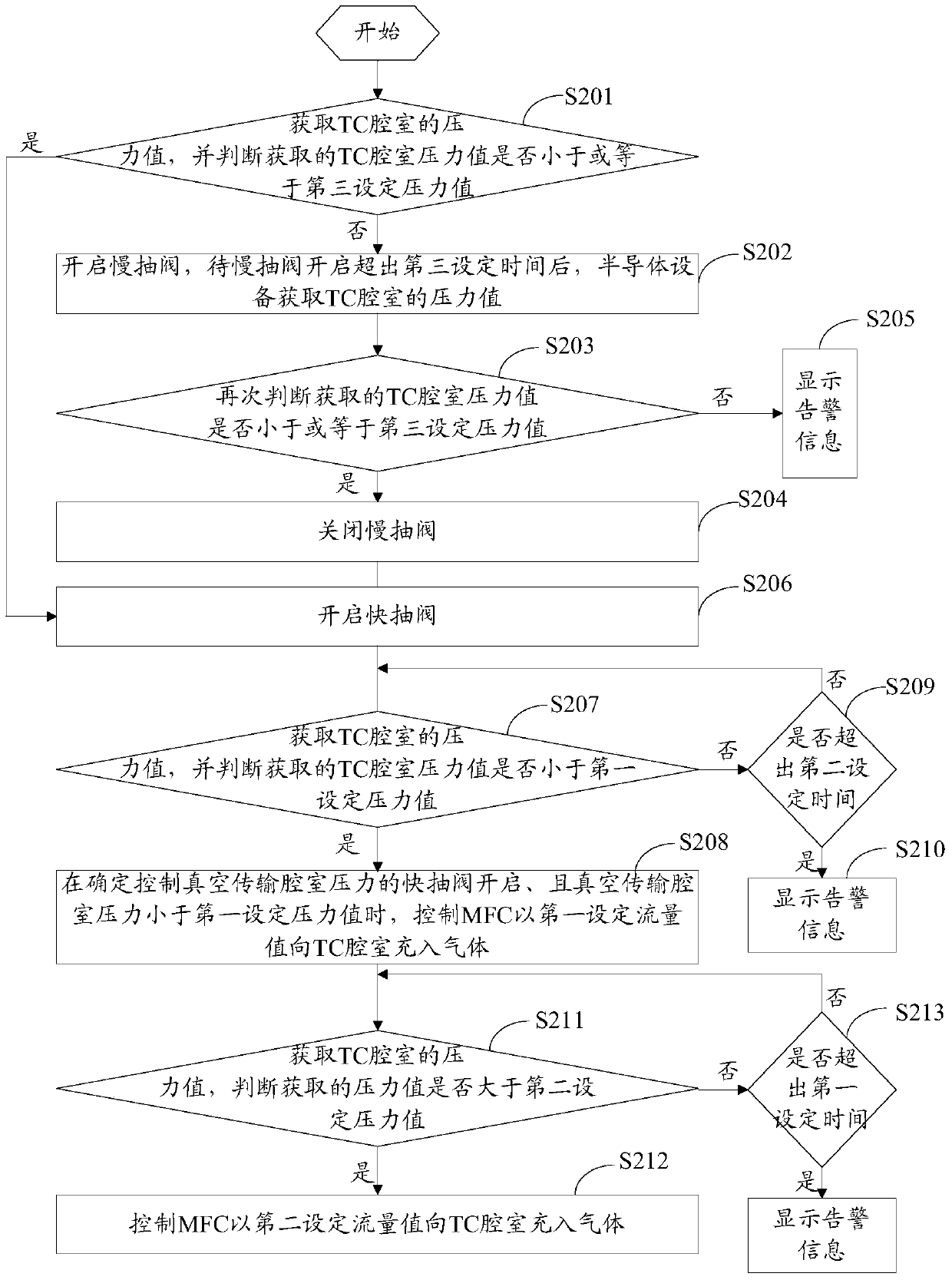

[0044] refer to image 3 , shows a flow chart of the steps of a pressure control method in Embodiment 2 of the present invention.

[0045] In this embodiment, in order to solve the problem that the PM chamber emits residual gas to the TC chamber during the process of transferring wafers between the PM chamber and the TC chamber in the existing semiconductor equipment, a simultaneous control method for the TC chamber and the PM chamber is adopted. The method of pressure means that when the machine is in normal state, the pressure of the PM chamber is controlled within a certain range, while the pressure of the TC chamber is slightly greater than the pressure of the PM chamber. In the implementation process, the existing TC chamber needs to be improved, and an MFC is added outside the TC chamber to input gas (such as high-purity N 2 , and at the same time open the quick pumping valve to realize the dynamic balance of the pressure in the TC chamber.

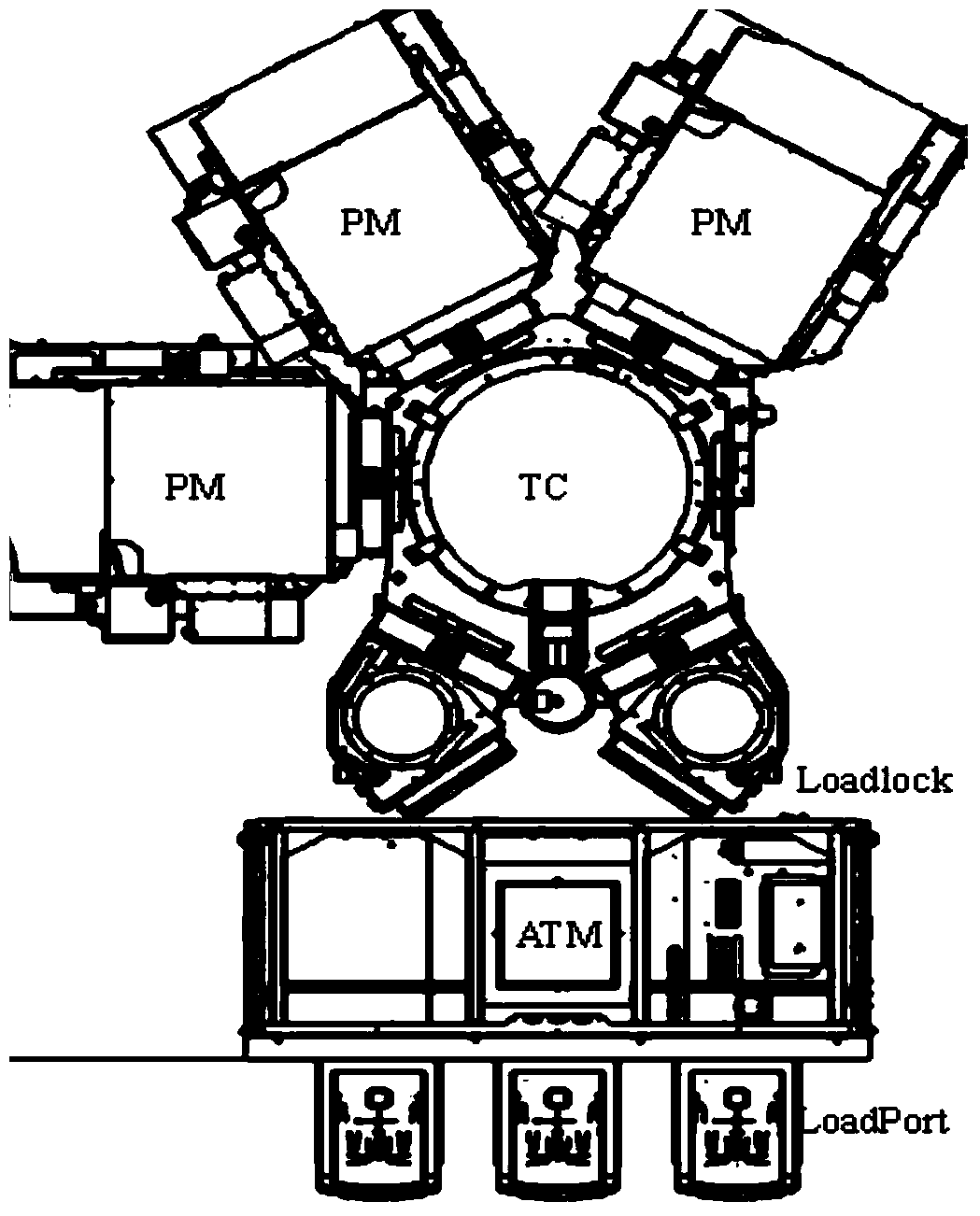

[0046] The structure of th...

Embodiment 3

[0083] refer to Figure 5 , shows a structural block diagram of a pressure control device according to Embodiment 3 of the present invention.

[0084] The pressure control device in this embodiment is set on the semiconductor device, and specifically includes: a first control module 501, which is used to determine that the pumping valve controlling the pressure of the vacuum transmission chamber is opened, and the pressure of the vacuum transmission chamber is lower than the first setting pressure value, control the mass flow controller to fill the vacuum transfer chamber with gas at the first set flow rate; the acquisition module 502 is used to obtain the pressure value of the vacuum transfer chamber; the second control module 503, When the pressure value acquired by the acquisition module is greater than a second set pressure value, control the mass flow controller to fill the vacuum transfer chamber with gas at the second set flow rate, wherein the first A set flow value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com