Device and method for detecting coal seam gas pressure and coal wall stress

A coal seam gas pressure and detection device technology, which is applied to measuring devices, fluid pressure measurement by changing ohmic resistance, mining devices, etc., can solve problems such as inability to perform rapid detection, poor connection of air ducts, and long pressure recovery time, etc., to achieve Extensive practicability, fast detection speed, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

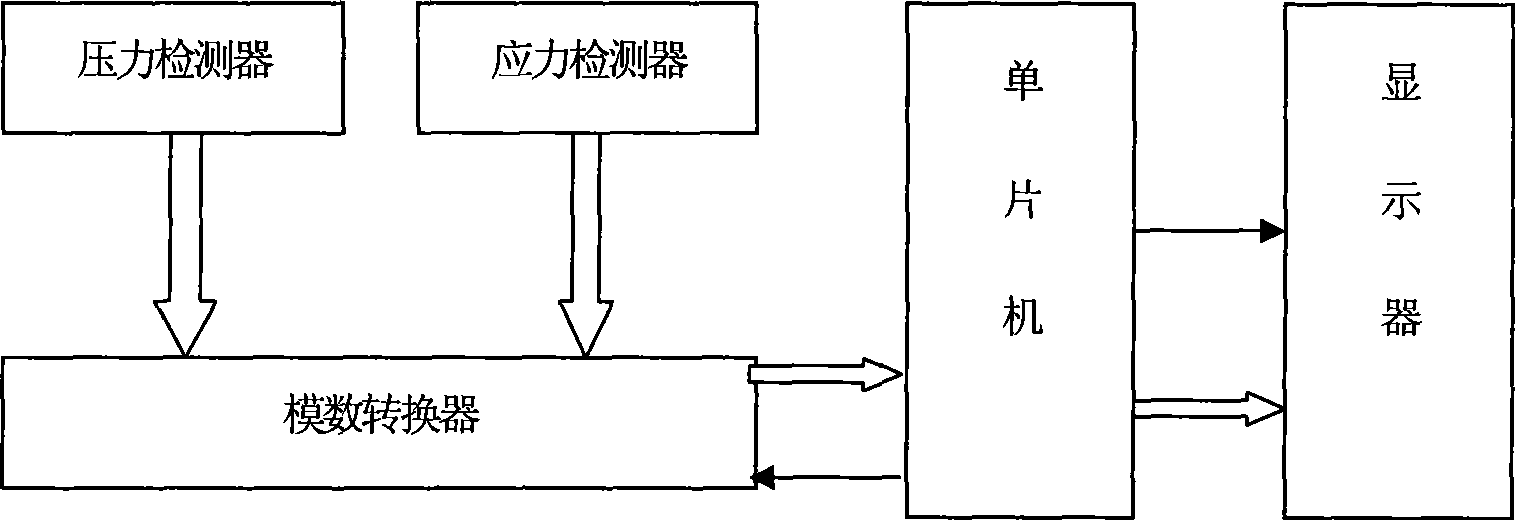

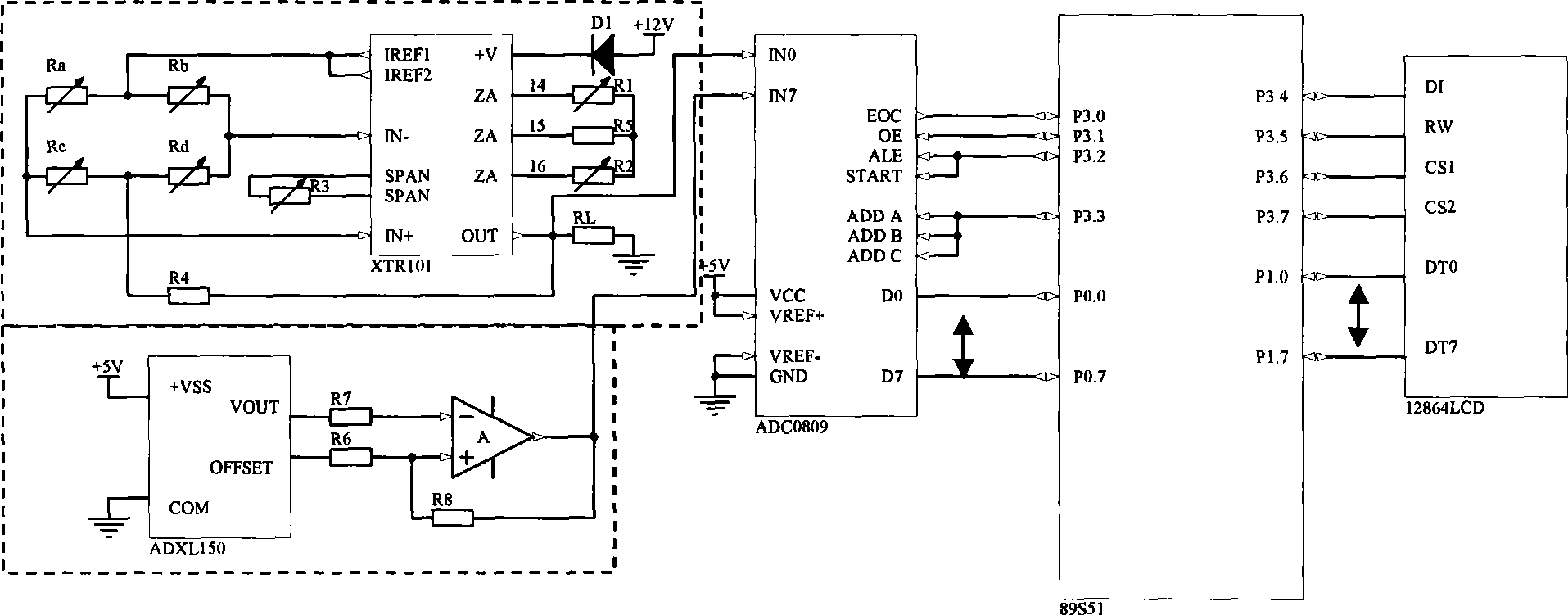

[0015] figure 1 As shown, it is composed of a pressure detector, a stress detector, an analog-to-digital converter, a single-chip microcomputer and a display. The output ends of the A / D converters are respectively connected with the analog-to-digital converters located outside the coal wall drilling, the output ends of the A / D converters are connected to the input ends of the single-chip microcomputer, the output ends of the single-chip microcomputer are connected to the display, and the analog-to-digital converters are connected by connecting the single-chip microcomputer and the The monitor connected to the single chip computer displays the data. When the pressure detector and stress detector in the coal wall borehole detect the corresponding pressure and stress, the pressure detector converts the detected gas pressure information into a standard cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com