Electric vehicle power battery box liquid leakage detection system and detection method thereof

A power battery and electric vehicle technology, applied in the field of electric vehicle power battery box leakage detection system, can solve problems such as damaged electrolyte, potential safety hazards, battery failure capacity attenuation, etc., achieve flexible use, high degree of intelligence, and improve driving safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

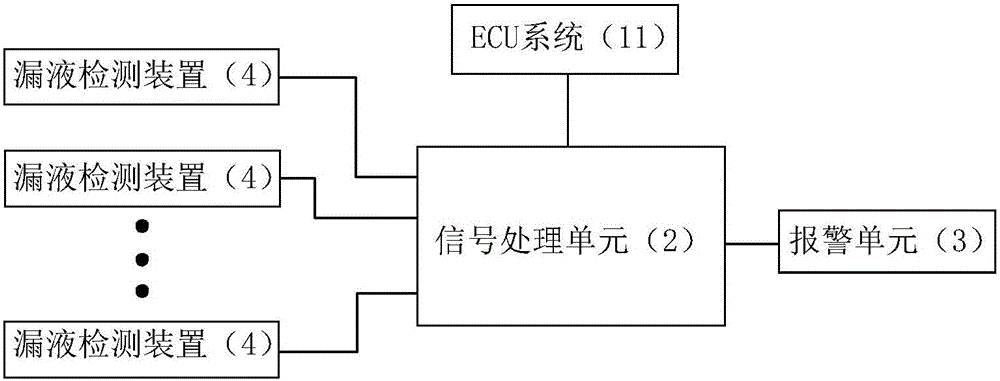

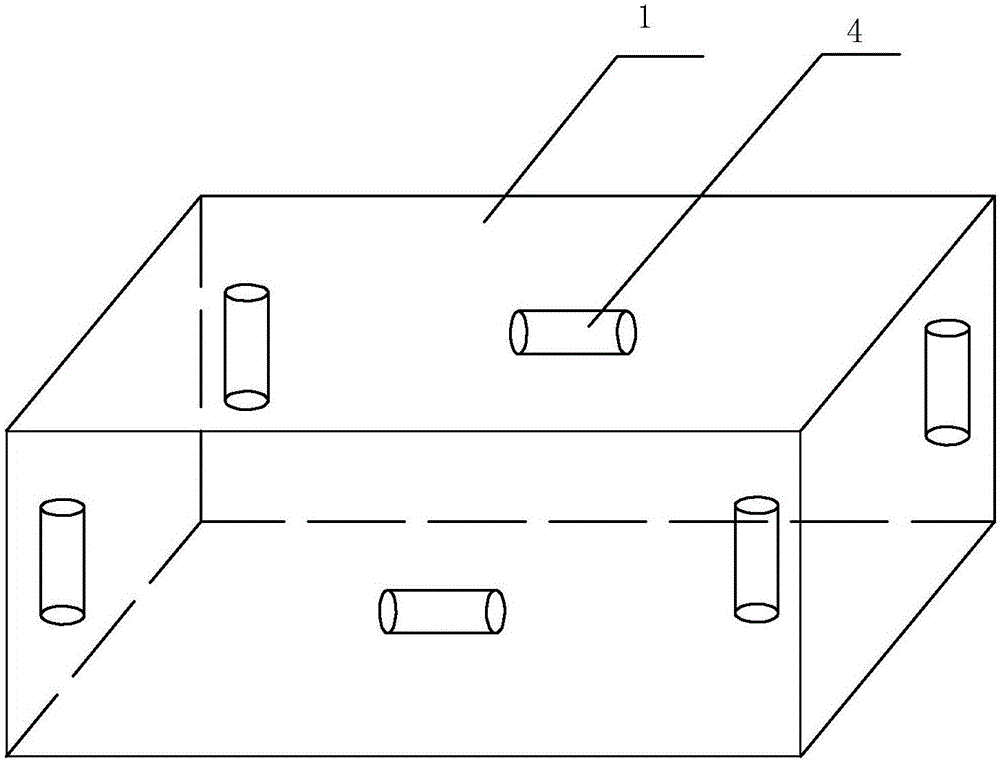

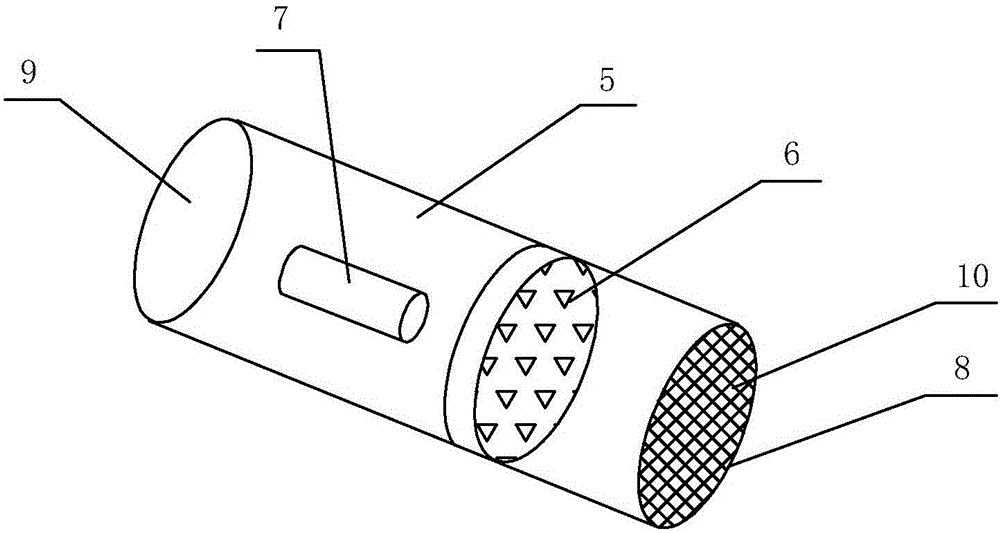

[0019] Embodiment: the liquid leakage detection system of the electric vehicle power battery case of the present embodiment, such as figure 1 As shown, it includes six liquid leakage detection devices 4 installed in the electric vehicle power battery box 1, a signal processing unit 2 and an alarm unit 3 installed on the dashboard of the electric vehicle cab, wherein the four liquid leakage detection devices are respectively Installed at the four corners of the power battery box 1, and in a vertical installation state, the remaining two liquid leakage detection devices are respectively installed on the two longer side walls of the power battery box, and are in a horizontal installation state, such as figure 2 shown. The output terminals of the six liquid leakage detection devices 4 are respectively connected to the six input terminals of the signal processing unit 2 , and the output terminals of the signal processing unit 2 are connected to the control terminal of the alarm un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com