Stator base for three-degree-of-freedom spherical rotor ultrasonic motor

A spherical rotor, ultrasonic motor technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as insufficient driving capacity, complex structure, and insufficient driving feet. , to achieve the effect of simple structure, improved driving ability and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

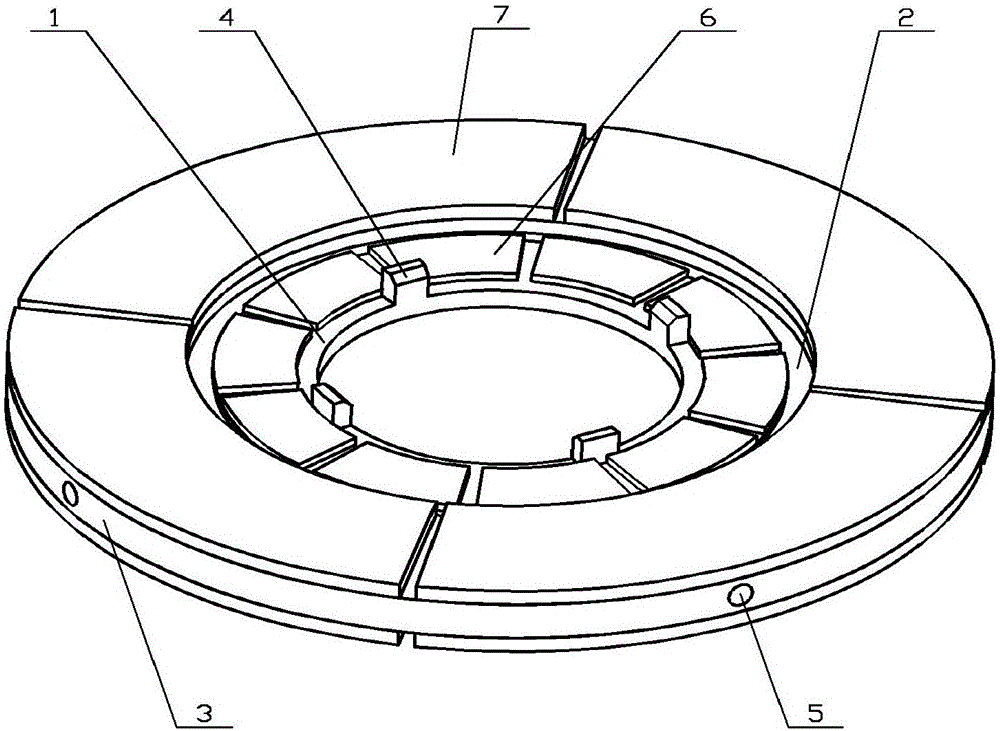

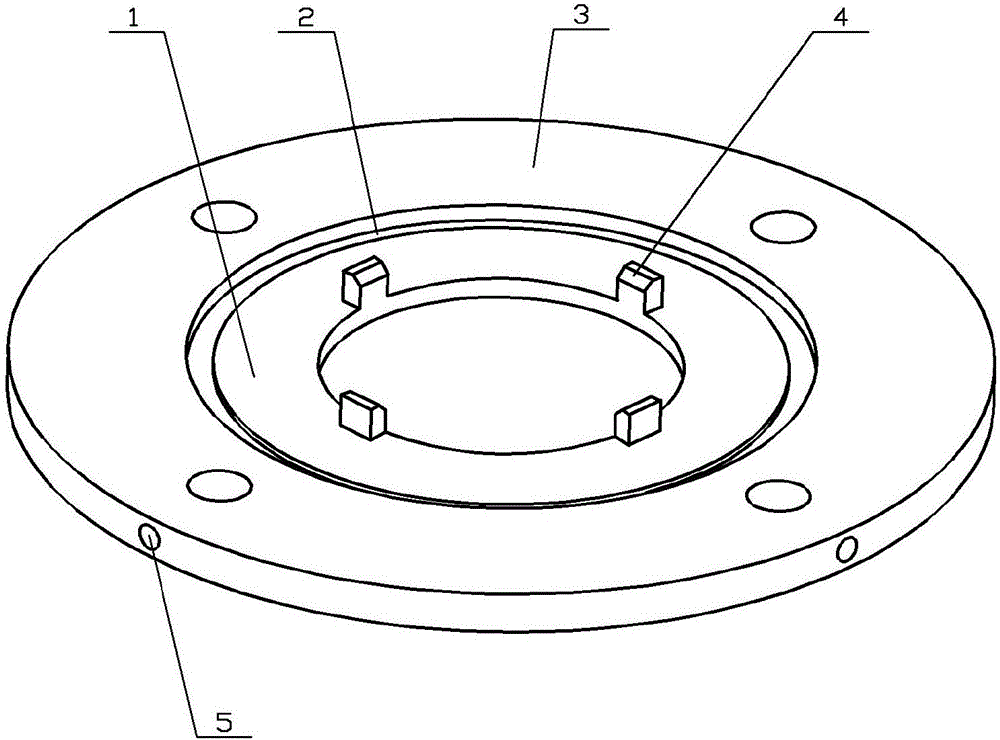

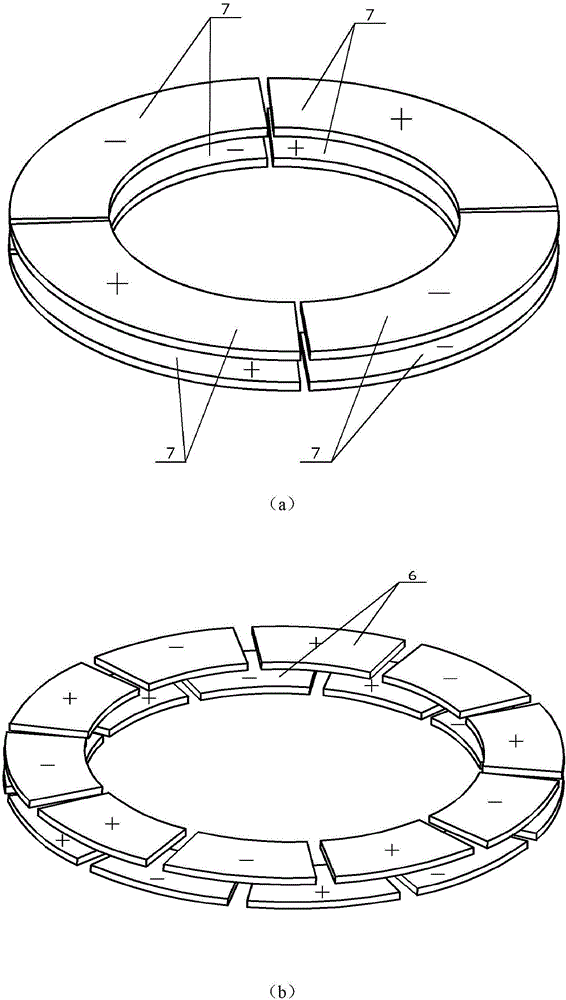

[0013] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment. The stator base of the three-degree-of-freedom spherical rotor ultrasonic motor described in this embodiment includes an axial vibration ring 1, a vibration isolation ring 2, a radial vibration ring 3, four driving feet 4, and two sets of axial vibration rings. Ring piezoelectric ceramic sheet group and two groups of radial vibration ring piezoelectric ceramic sheet groups; axial vibration ring 1, vibration isolation ring 2 and radial vibration ring 3 are coaxially arranged; wherein axial vibration ring 1 and radial vibration ring 3 is connected through the vibration isolation ring 2 in the middle; the upper surface of the axial vibration ring 1 is arranged with four driving feet 4 along the circumferential direction; the upper and lower surfaces of the axial vibration ring 1 are respectively fixed with a group of axial vibration ring piezoelectric ceramics Sheet group, each axial ...

specific Embodiment approach 2

[0015] Specific Embodiment 2: This embodiment is a further limitation on the stator base of the three-degree-of-freedom spherical rotor ultrasonic motor described in Embodiment 1. In this embodiment, the axial vibration ring 1, the vibration isolation ring 2 and the radial vibration ring 3 in one piece. The axial vibration ring 1 is located inside the vibration isolation ring 2, the radial vibration ring 3 is located outside the vibration isolation ring 2, and the vibration isolation ring 2 is located in the middle, and its thickness is smaller than that of the axial vibration ring 1 and the radial vibration ring 3. This arrangement can make the axial vibration of the axial vibration ring 1 not have a great influence on the radial vibration of the radial vibration ring 3, and at the same time, the radial vibration of the radial vibration ring 3 can be effectively coupled to the internal driving foot Above all, the axial vibration of the axial vibration ring 1 and the radial vi...

specific Embodiment approach 3

[0016] Specific Embodiment 3: This embodiment is a further limitation of the stator base of the three-degree-of-freedom spherical rotor ultrasonic motor described in Embodiments 1 and 2. In this embodiment, four driving feet 4 are evenly arranged, that is, two adjacent driving legs 4 The spatial phase difference between the feet is 90°.

[0017] Such an arrangement is conducive to forming an elliptical driving track with a higher amplitude, and at the same time, the symmetrical driving feet are beneficial to improving the stability of the stator base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com