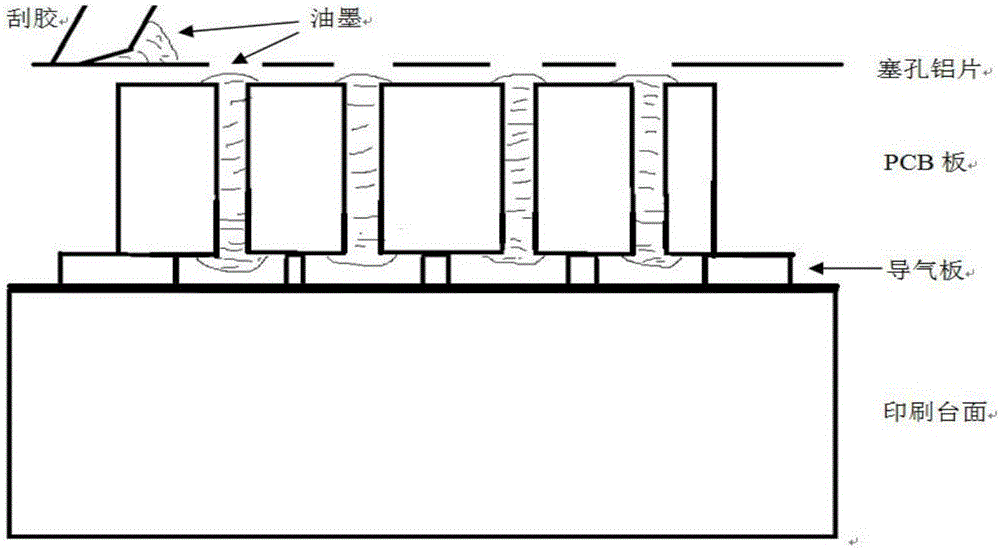

Printed gas-guiding board

A technology of air guide plate and substrate, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc. It can solve the problems of lack of support points, air guide plate falling off, etc., and achieve good air guide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

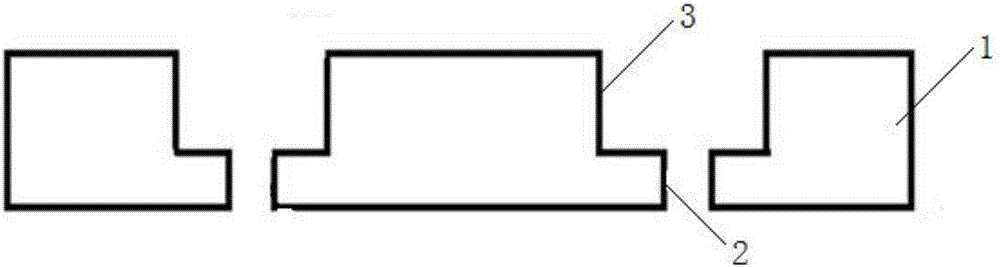

[0017] refer to image 3 , a printed air guide plate, including a substrate 1, the substrate 1 is provided with a borehole through the substrate, the borehole is composed of a first borehole 2 and a second borehole 3, the second borehole 2 Located above the first borehole 3 , and the second borehole 2 communicates with the first borehole 3 .

[0018] In this embodiment, the drilled holes penetrating the substrate are in an inverted "convex" shape.

[0019] In this embodiment, the thickness of the substrate 1 is 2.0mm.

[0020] In this embodiment, the diameter of the first borehole 2 is 0.4mm.

[0021] In this embodiment, the drilling depth of the second drilling 3 is 1.2mm, and the diameter is 2.0mm (ensure that the diameter of the hole is 1.0mm larger than that of the plug hole to prevent the ink from sticking to the air guiding plate).

[0022] Its production method: use a 2.0mm substrate as the carrier, use a 0.4mm drill bit to drill through, and use 2.0mm at the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com