Rotary electric machine stator fitted with optimized coil

A technology for rotating electrical machines and stators, which is applied in the manufacture of motor generators, prefabricated windings embedded in motors, electrical components, etc. It can solve problems such as inability to allow and no time to allow stator sintering flux to melt, so as to ensure continuity, optimize manufacturing time, The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

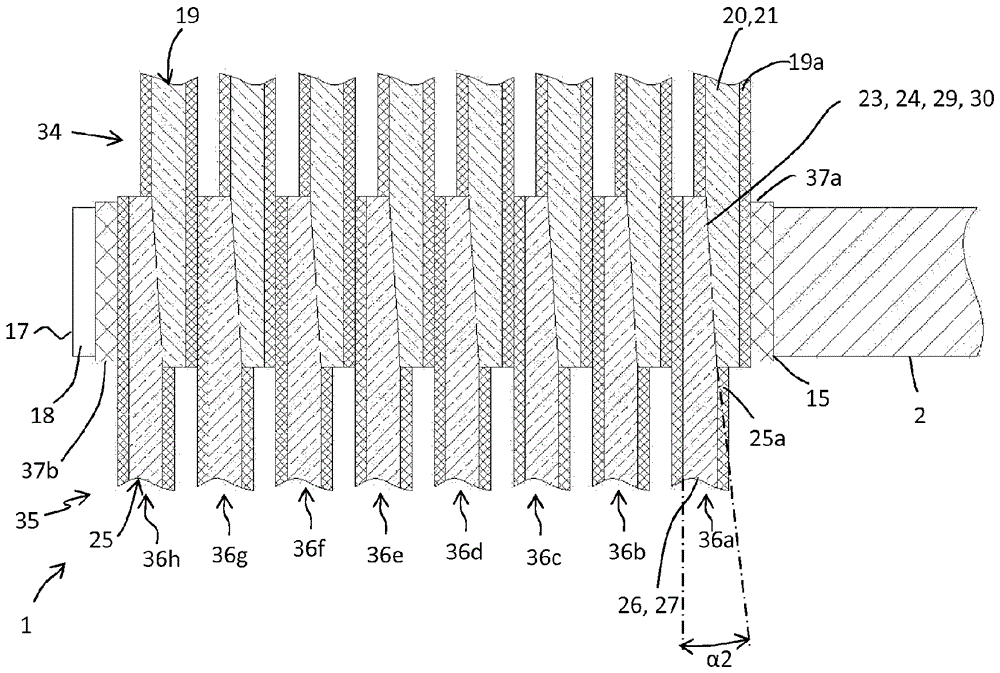

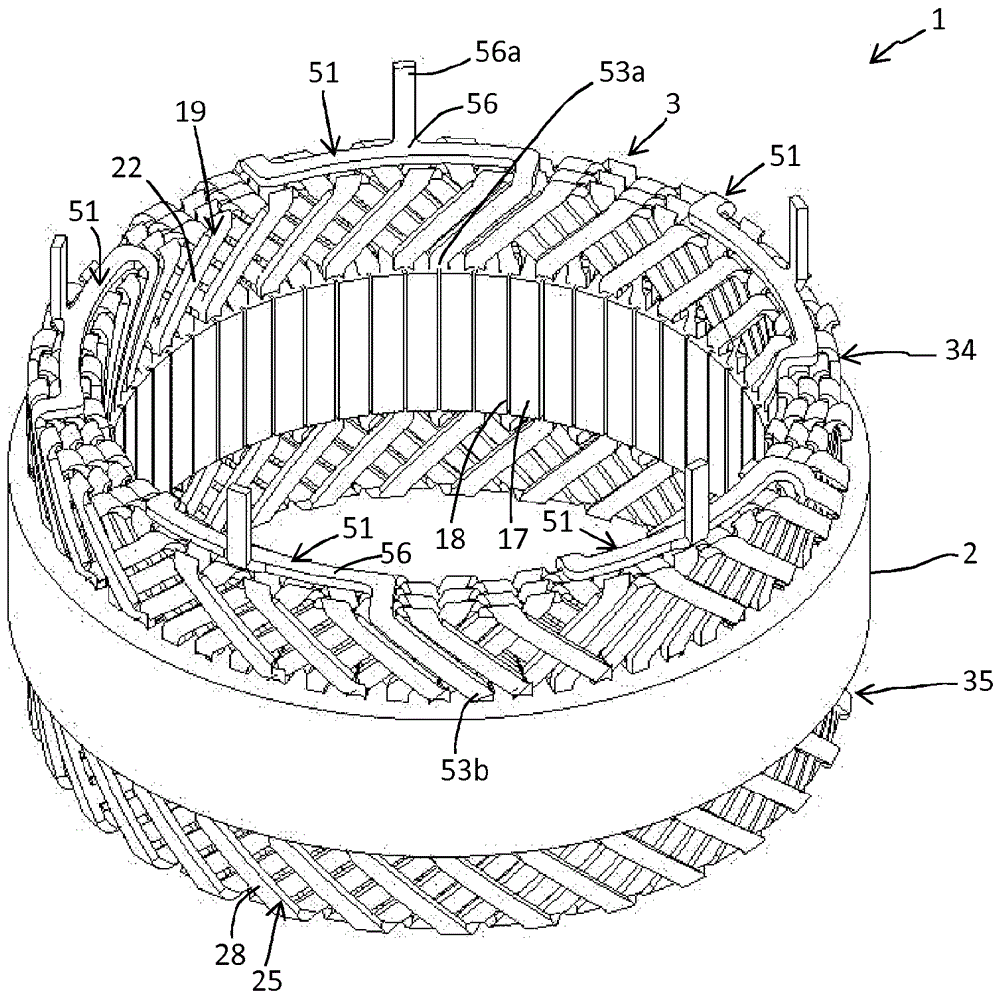

[0062] In the following description, the same reference numerals are used to identify a part of the stator object of the invention and / or the same elements on the different variants.

[0063] figure 1 A stator 1 of a rotating electrical machine (not shown) comprising a motor or generator is shown in . In one application, the stator 1 is intended to implement a generator or generator-starter of a motor vehicle.

[0064] This stator 1 includes a body 2 and a coil 3 . here figure 1 , the coil 3 comprises five phases 4, 5, 6, 7, 8, each phase consists of a single winding on six layers 9, 10, 11, 12, 13, 14, which in Figure 6A and Figure 6B shown in more detail. Of course, the number of phases may vary; for example three phase coils may be provided, each phase comprising a single winding. It is also possible to vary the number of windings per phase; for example two windings per phase could be provided. It is also possible to vary the number of layers per winding.

[0065]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com