A jig for welding elbows of automobile mufflers

An automobile muffler and pipe bending technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inaccurate welding positioning, welding deformation and looseness at the joint between the bending pipe and the special-shaped plate, and achieves the guarantee Welding quality, effects of avoiding shifting or loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and embodiments.

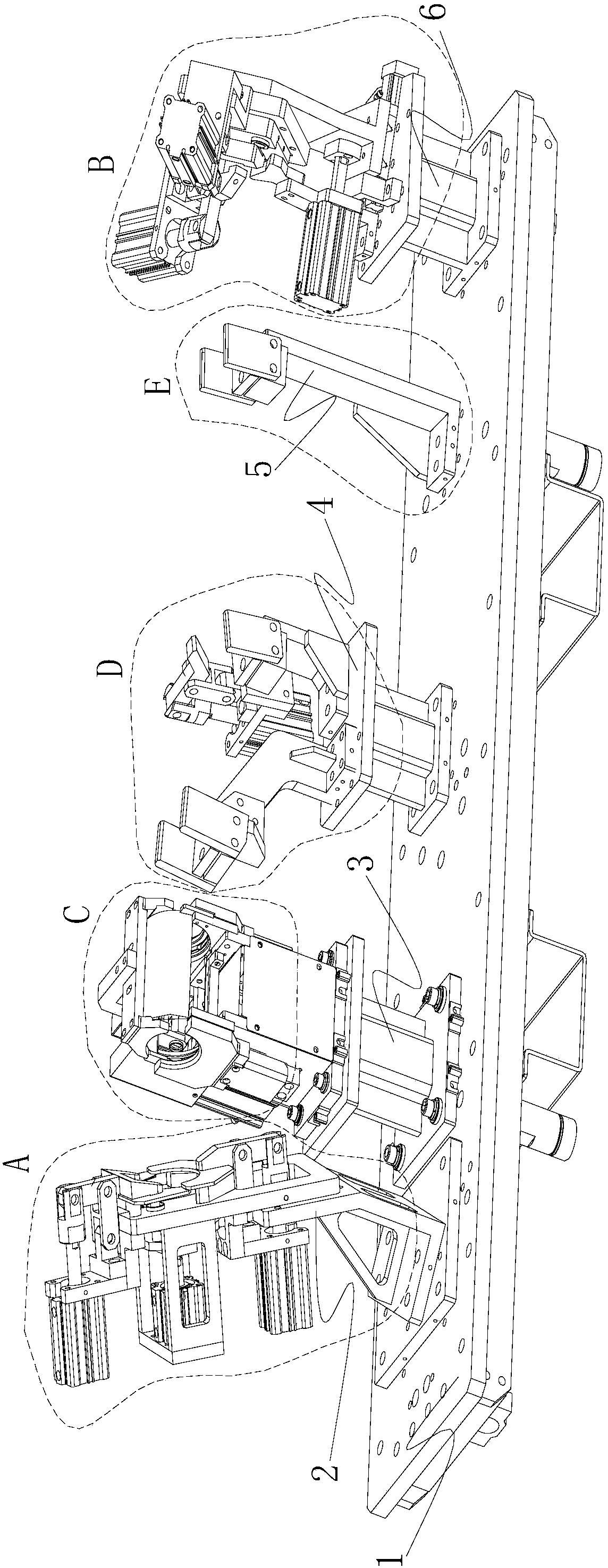

[0027] As shown in the figure, the fixture for welding elbow pipe of automobile muffler is provided with a left clamping seat 2, a first support frame 3, a second support frame 4, and a third support on the frame 1 of the fixture in turn from left to right The frame 5 and the right clamping base 6, the first supporting frame 3, the second supporting frame 4 and the third supporting frame 5 are arranged in sequence, and the first supporting frame 3 is closest to the left clamping base 2.

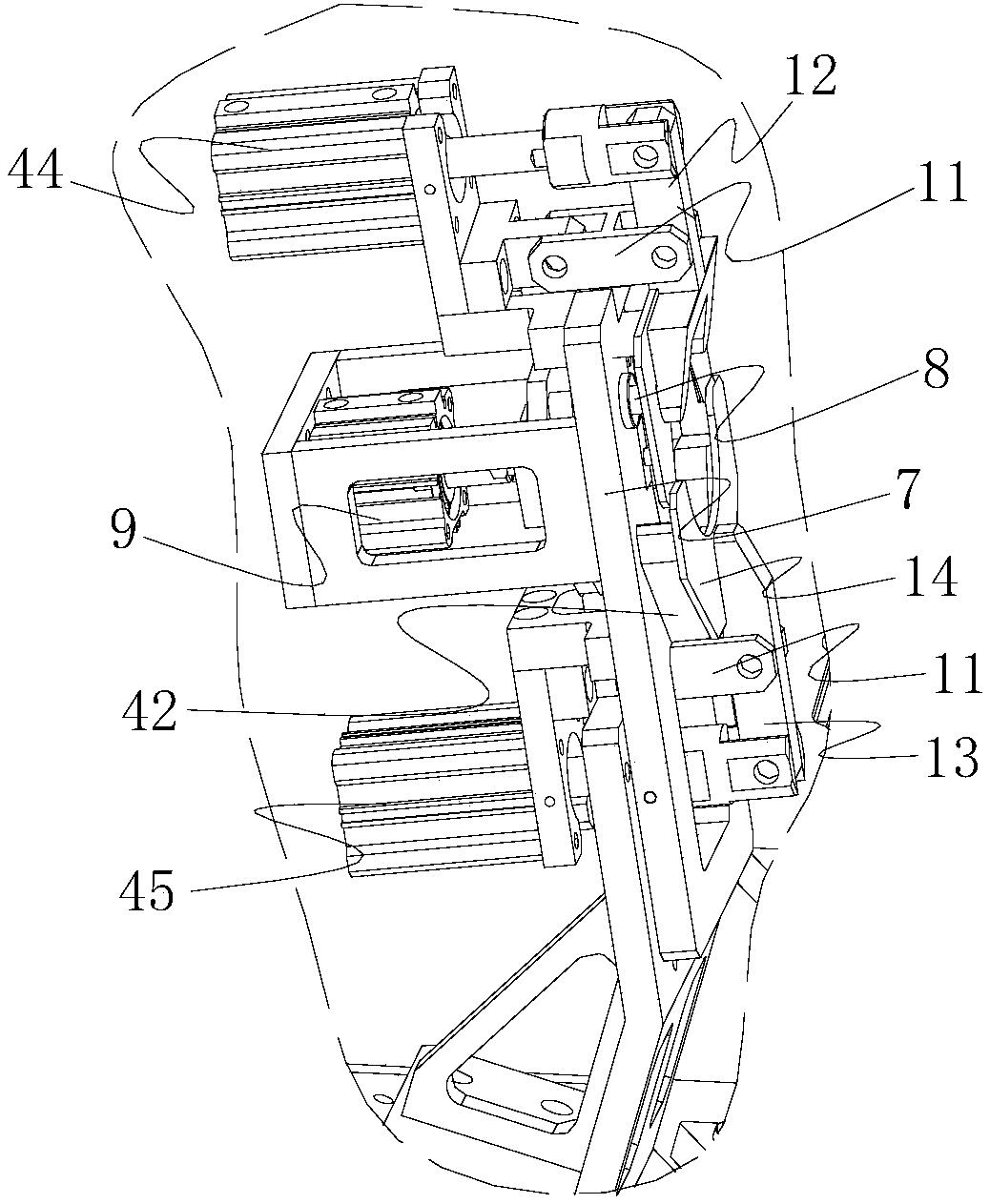

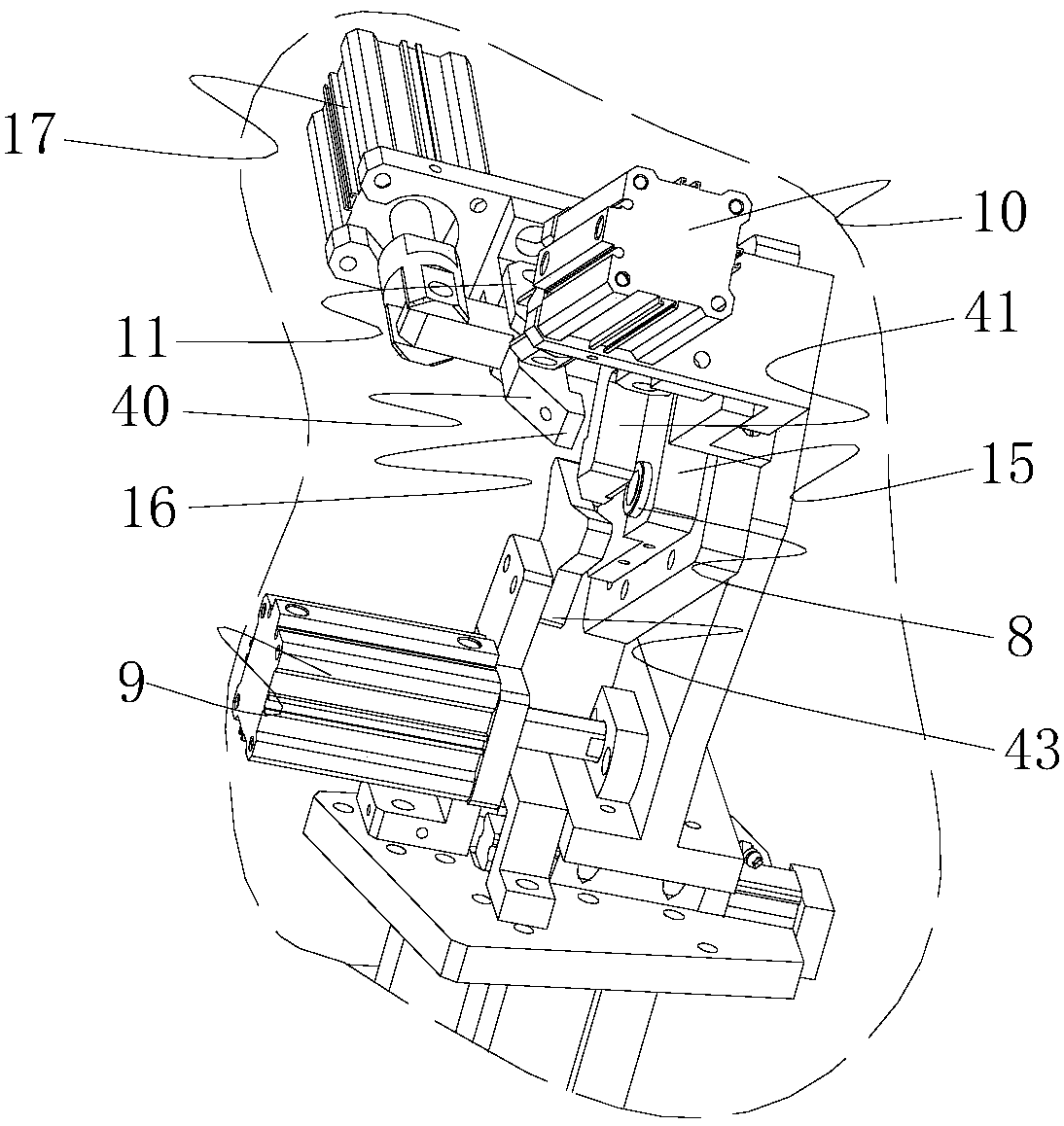

[0028] In this embodiment, the left clamping seat 2 includes a left support table 7 having a plate-like structure. The left support table 7 is provided with three support columns 8 for workpiece positioning and a support column cylinder 9 as a support column power mechanism. The piston rod of the support column cylinder 9 is connected to each support column 8 through a connecting plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com