Fabricated roof, construction method applying fabricated roof and building structure

A prefabricated and structural technology, applied in building structures, building components, roofs, etc., can solve the problems of inconvenient roof construction, high engineering cost, long time consumption, etc., and achieve the effect of saving on-site construction time and construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

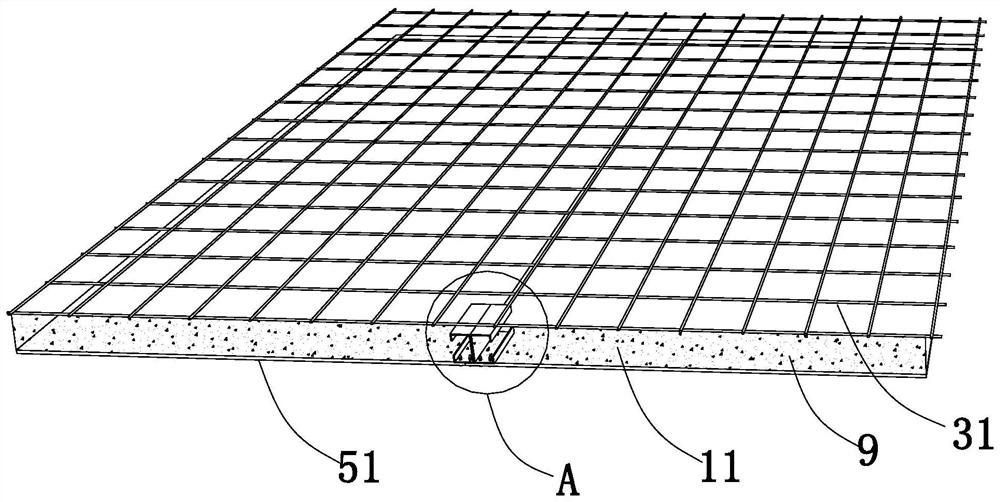

[0066] A prefabricated roof such as figure 1 with figure 2 As shown, it includes a roof installation position 21, a first reinforcing rib cage body 31, a first positioning member 41, a roof module 51, a thermal insulation layer 9, and a coagulation and fixing layer 6, as follows;

[0067] Wherein, the roof installation position 21 matches the preset specifications of the roof; the roof module 51 is set according to the specifications of the roof installation position 21, and is arranged along the bottom surface of the roof installation position 21; the first reinforcing rib cage body 31, the first positioning Part 41 is set according to the specification of roof installation position 21; Spacing 11.

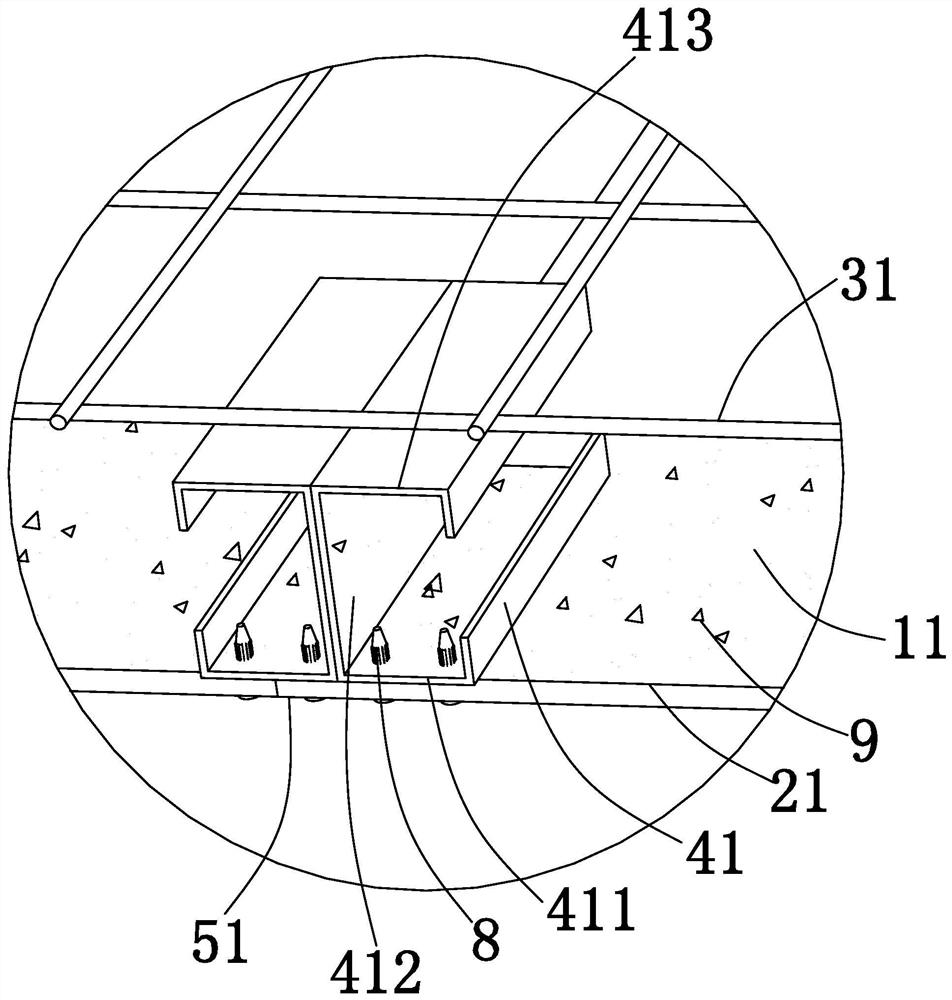

[0068] Wherein, the first positioning member 41 includes a first longitudinal portion 412, a first transverse portion 411, and a second transverse portion 413; the second positioning member 42 has two specific implementation modes, specifically as follows:

[0069] When the f...

Embodiment 2

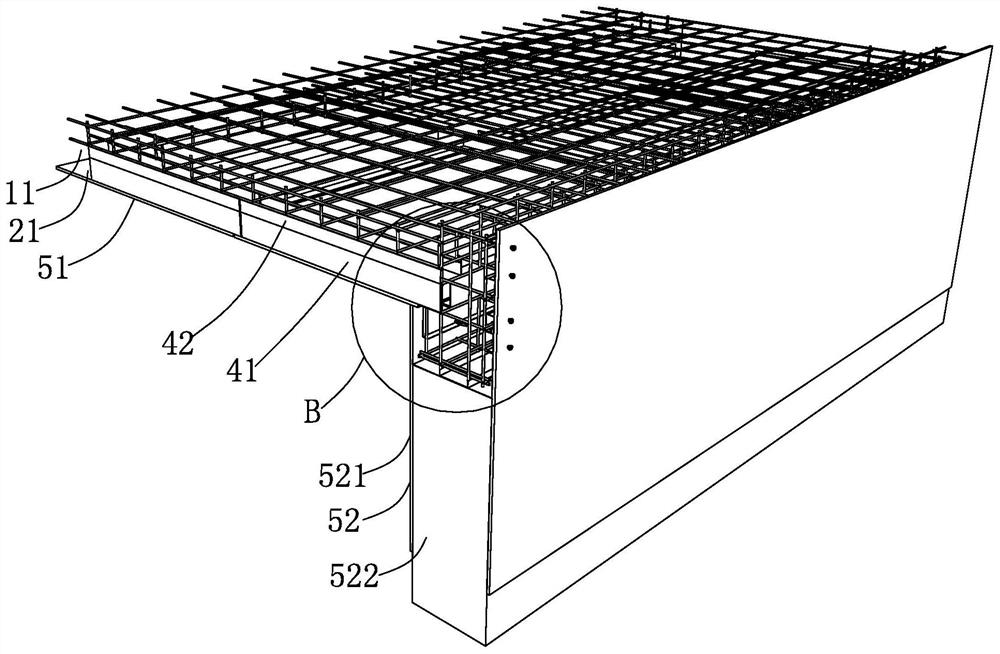

[0082] Such as image 3 with Figure 4 As shown, the difference between the second embodiment and the first embodiment is that: a second positioning member 42 is also provided between the first reinforcement cage body 31 and the first positioning member 41;

[0083] Such as Figure 5 with Image 6 As shown, the second positioning member 42 is connected to the first reinforcement cage body 31 on one side, and connected to the first positioning member 41 on the other side; wherein Figure 5 It is an omitted partial schematic diagram, and the right side of the section line represents the structure of the first reinforcement cage body 31 extending infinitely; by setting the second positioning member 42, there is formed between the first reinforcement cage body 31 and the first positioning member 41 for The second space 12 of the coagulation-fixed layer 6 is filled.

[0084]The second spacing 12 can be used to fill the solidified and fixed layer 6; by predetermining the height ...

Embodiment 3

[0089] A construction method, which is applied as a prefabricated roof as described in Embodiment 1, comprising the steps of:

[0090] pre-installed:

[0091] A roof installation position 21 is preset;

[0092] According to the roof installation position 21, it is divided into several roof modules 51, and each roof module 51 is correspondingly provided with several first reinforcement cages 31 through the first positioning;

[0093] Assembly process:

[0094] Arranging several roof modules 51 along the bottom surface of the roof installation position 21;

[0095] Filling process:

[0096] First, fill the thermal insulation layer 9 into the first space 11 formed between the first reinforcing rib cage body 31 and the roof module 51; after the thermal insulation layer 9 is formed, fill the solidified layer 6 into the roof installation position 21 , so that the coagulation-fixed layer 6 fills the first reinforcing rib cage body 31 .

[0097] Embodiment 3 provides a specific c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com