Pre-dividing location mould for grinding of crankshaft connecting rod journal

A technology for positioning molds and connecting rod necks, which is applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of crankshaft and positioning disc slippage, insufficient pressing, time-consuming pressing, etc., to avoid Dimensional deformation, convenient compression, simple manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

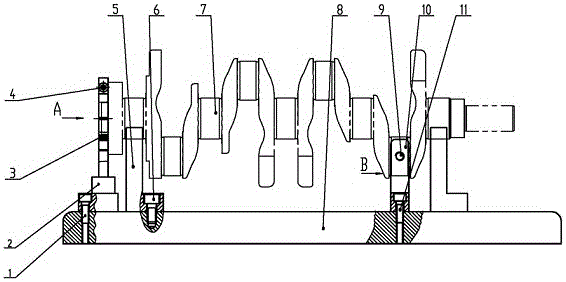

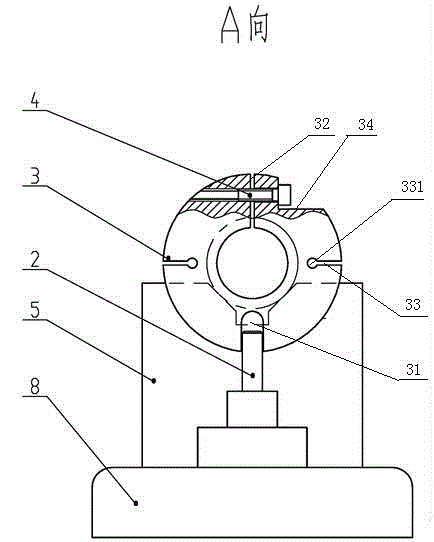

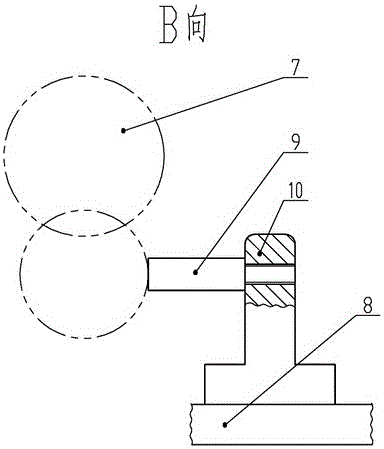

[0013] From figure 1 , figure 2 , image 3 It can be seen from the figure that a pre-indexed positioning mold for crankshaft grinding pin neck includes a positioning plate 3, a positioning column 2, a support body 8, a crankshaft 7, and the like. Crankshaft 7 is installed on the crankshaft support positioning mechanism. The support positioning mechanism includes a V-shaped support block 5 and a positioning seat 10 installed on the support body 8 , and the two V-shaped support blocks 5 and the positioning seat 10 are fixed by bolts 6 and 11 . Two V-shaped support blocks 5 are supported under the main journals at both ends of the crankshaft 7, and the positioning seat 10 is supported on the side of a connecting rod neck of the crankshaft 7, on which a crankshaft connecting rod neck circumferential positioning column 9 is horizontally connected, and the circumferential positioning column 9 One end is fixed on the positioning seat 10 with threads, and the other end locates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com