Tire installation structure achieving turning resisting function under condition of blowout

A technology for installing structures and tires, which is applied to tire parts, wheels, transportation and packaging, etc. It can solve problems such as no technical solutions and tire blowouts, and achieve the effects of easy popularization, reduced use costs, and solutions to car out-of-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

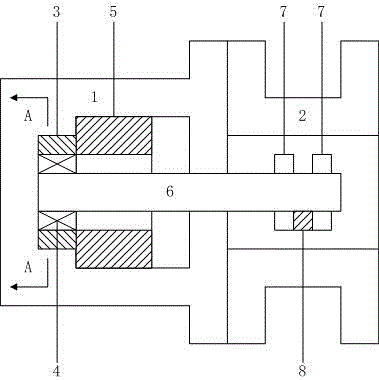

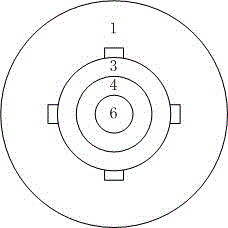

[0028] The tire mounting structure with the function of puncture and steering prevention of this embodiment, the schematic diagram of the structure is as figure 1 Shown. The tire mounting structure includes a transmission shaft 1 and a hub 2 bolted to the transmission shaft 1;

[0029] The transmission shaft 1 is provided with a stepped blind hole along the axial direction, the bottom step part of the stepped blind hole is provided with a plurality of blind grooves evenly arranged in the circumferential direction, and the blind groove is installed with a circular through hole in the middle. Multi-grasping structure 3, the claws of the multi-grasping structure 3 are installed in the blind groove, the circular through hole in the middle of the multi-grasping structure 3 is in interference fit with the outer ring of the bearing 4; the inner wall of the top stepped part of the stepped blind hole The threaded ring fixing ring 5 is screwed to the bottom of the top stepped part through ...

specific Embodiment 2

[0035] The tire mounting structure with puncture prevention and steering function of this embodiment, on the basis of specific embodiment 1, further defines the inner surface of the groove connecting part, and is also equipped with a rubber layer.

[0036] Under the limitation of this structure, even if the nail is not shot at the tire, it will be absorbed by the rubber layer to avoid direct shot at the side wall of the hub, effectively protecting the hub and increasing the service life of the hub.

specific Embodiment 3

[0038] The tire mounting structure with the function of puncture and steering prevention of this embodiment, on the basis of specific embodiment 1, further restricts the structure diagram of the air nail gun 7 as Figure 4 As shown, the air nail gun 7 includes a nailing chamber 71, a pin 72 fixed in the nailing chamber 71 by an elastic material 76, and a compressed air chamber 74 provided with an electronic valve 73 behind the pin 72. The electronic The valve 73 is controlled by the control signal of the wireless receiving module 75; when the wireless receiving module 75 receives the control signal to detonate the tire, the electronic valve 73 is controlled to open, and the compressed air in the compressed air cavity 74 will be released instantly, causing the pin 72 to shoot toward Tires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com